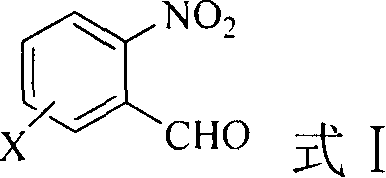

Method for synthesizing o-nitrobenzaldehyde compounds

A technology of o-nitrobenzaldehyde and its synthesis method, which is applied in the field of synthesis of o-nitrobenzaldehyde compounds, can solve problems such as difficult large-scale industrial production, and achieve the effect of simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

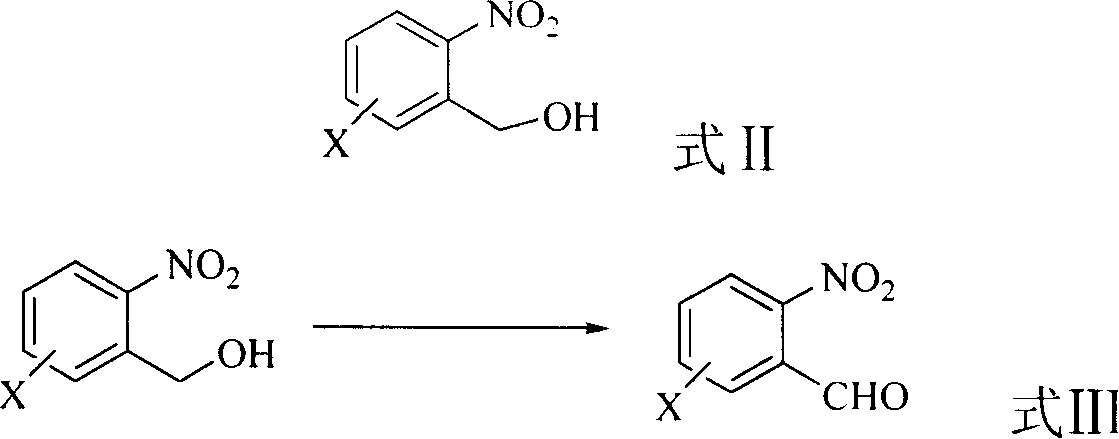

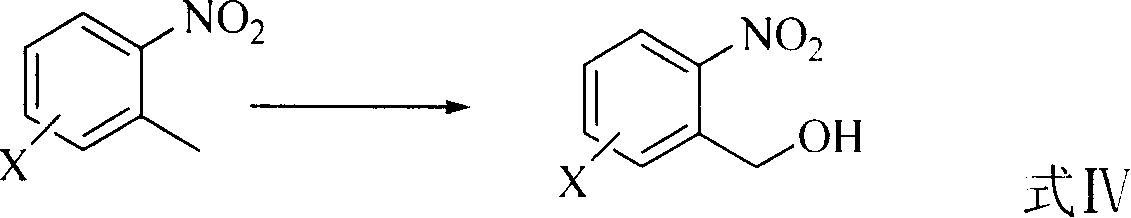

[0017] Embodiment 1 prepares 2-nitro-3-chlorobenzaldehyde

[0018] At room temperature, 2-nitro-3-chlorobenzyl alcohol (9.4g, 0.05mol), dichloromethane (100mL), BAIB (17.7g, 0.055mol) and TEMPO (0.75g, 5mmol) were successively added to the reaction flask , Stir evenly and then stir at 25-30°C until TLC traces the reaction of raw materials to complete (8h). After the reaction, add water (100mL) to the reaction solution, stir well and extract with dichloromethane (3×100mL), combine the organic phases, dry with anhydrous sodium sulfate, filter, and concentrate under reduced pressure to obtain 2-nitro-3- Chlorobenzaldehyde, the yield is 86%.

Embodiment 2

[0019] Embodiment 2 prepares 2-nitro-6-chlorobenzaldehyde

[0020] At room temperature, add 2-nitro-6-chlorobenzyl alcohol (9.4g, 0.05mol), chloroform (120mL), BAIB (40.1g, 0.125mol) and TEMPO (0.40g , 2.5mmol), stirred evenly and reacted at 10-15°C to TLC to track the complete reaction of raw materials (12h). After the reaction, add water (100mL) to the reaction solution, stir well and extract the aqueous phase with dichloromethane (3×100mL), concentrate and evaporate the organic solvent to obtain 2-nitro-6-chlorobenzaldehyde with a yield of 86%. .

Embodiment 3

[0021] Embodiment 3 prepares 2-nitro-6-bromobenzaldehyde

[0022] At room temperature, add 2-nitro-6-bromobenzyl alcohol (11.6g, 0.05mol), 1,1,2-trichloroethane (100mL), BAIB (24.1g, 0.075 mol) and TEMPO (1.5g, 10mmol), stirred evenly and then stirred at 35-40°C until TLC followed the complete reaction of the raw materials (7h). After the reaction, add water (100mL) to the reaction solution, stir well and extract the aqueous phase with dichloromethane (3×100mL), concentrate and evaporate the organic solvent to obtain 2-nitro-6-bromobenzaldehyde with a yield of 88%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com