Construction method for building of insulating brick

A construction method and technology of thermal insulation bricks, which are applied to buildings, building components, building structures, etc., can solve problems such as peeling back to alkali, long hair, condensation, etc., to reduce difficulty and cost, prolong service life, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

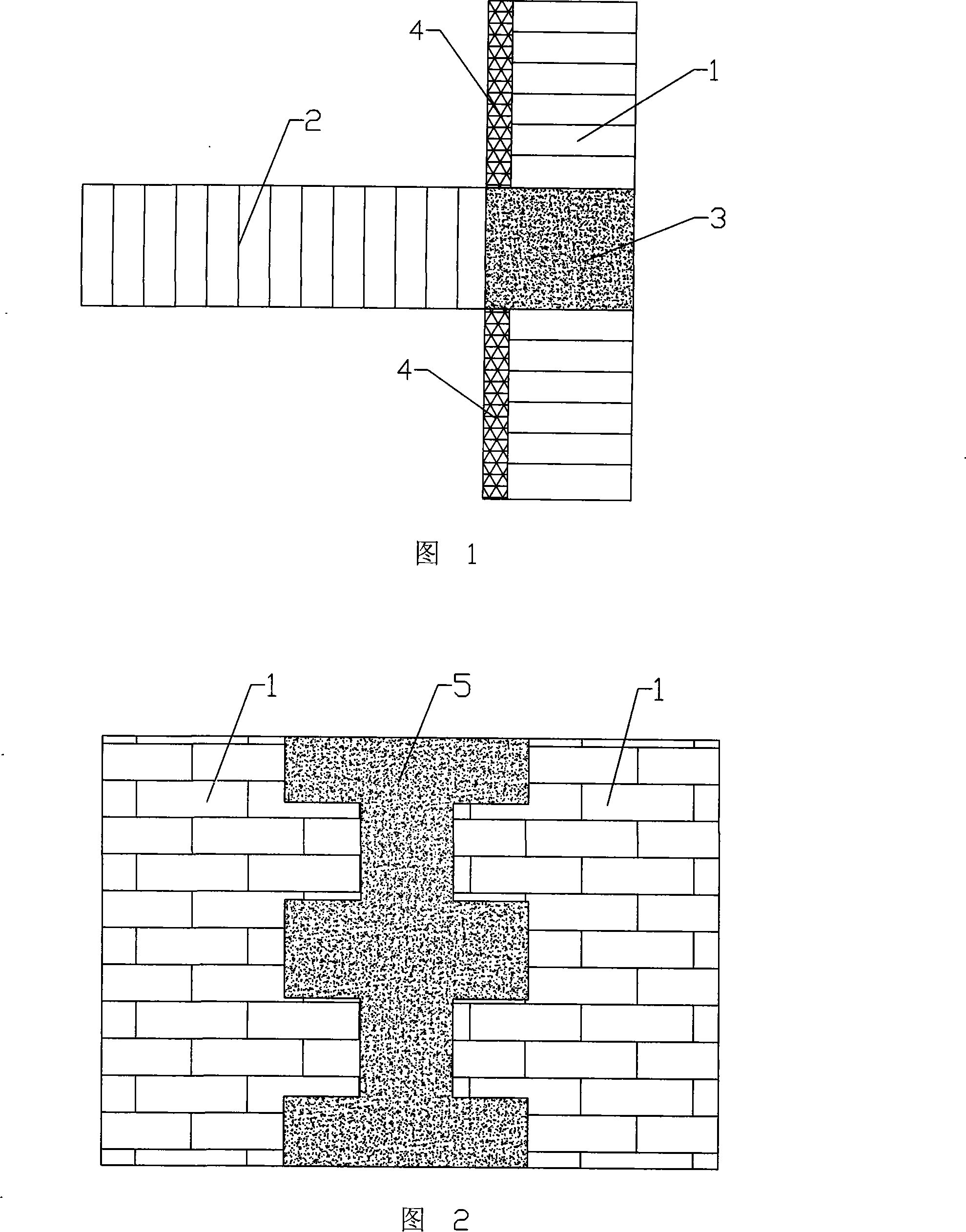

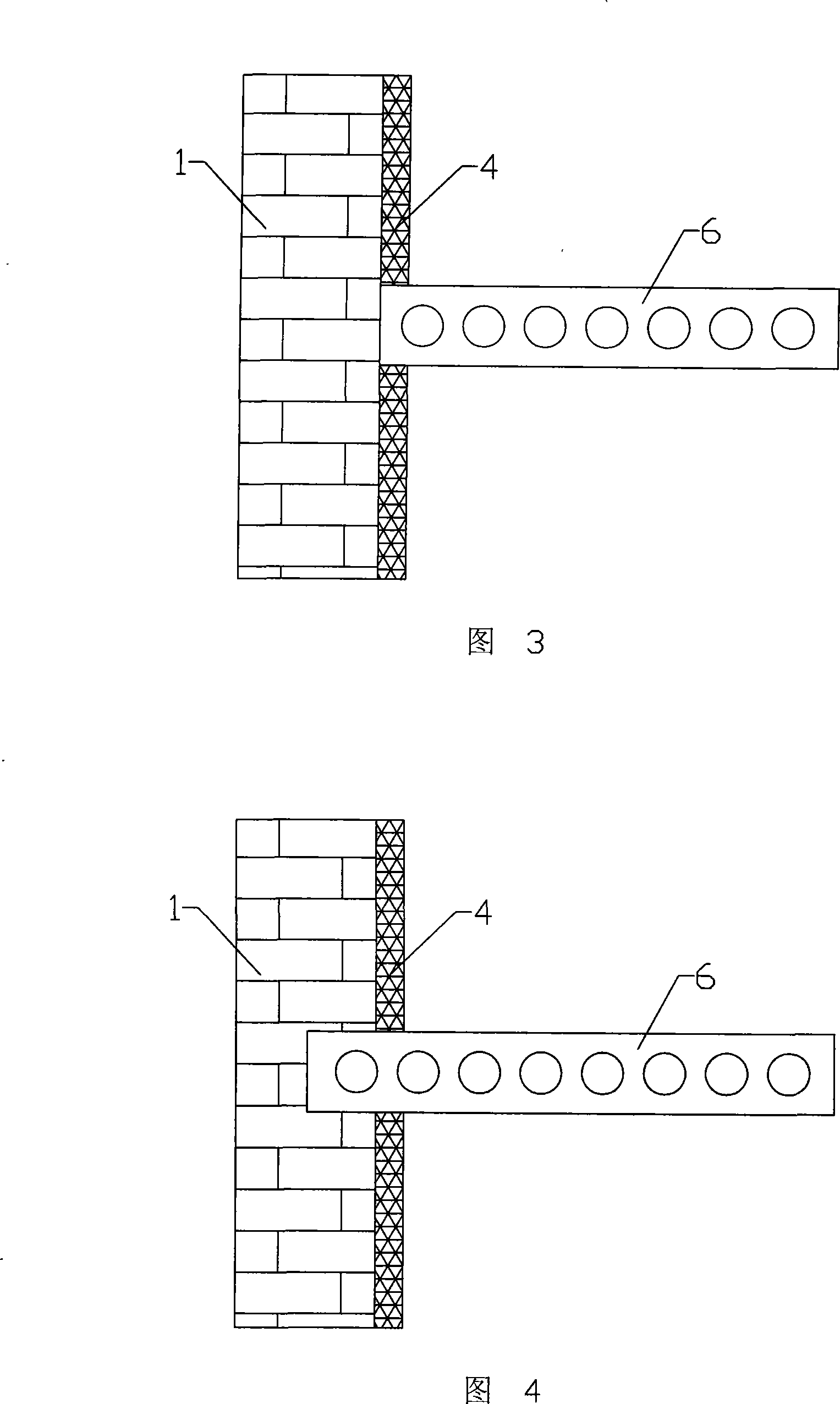

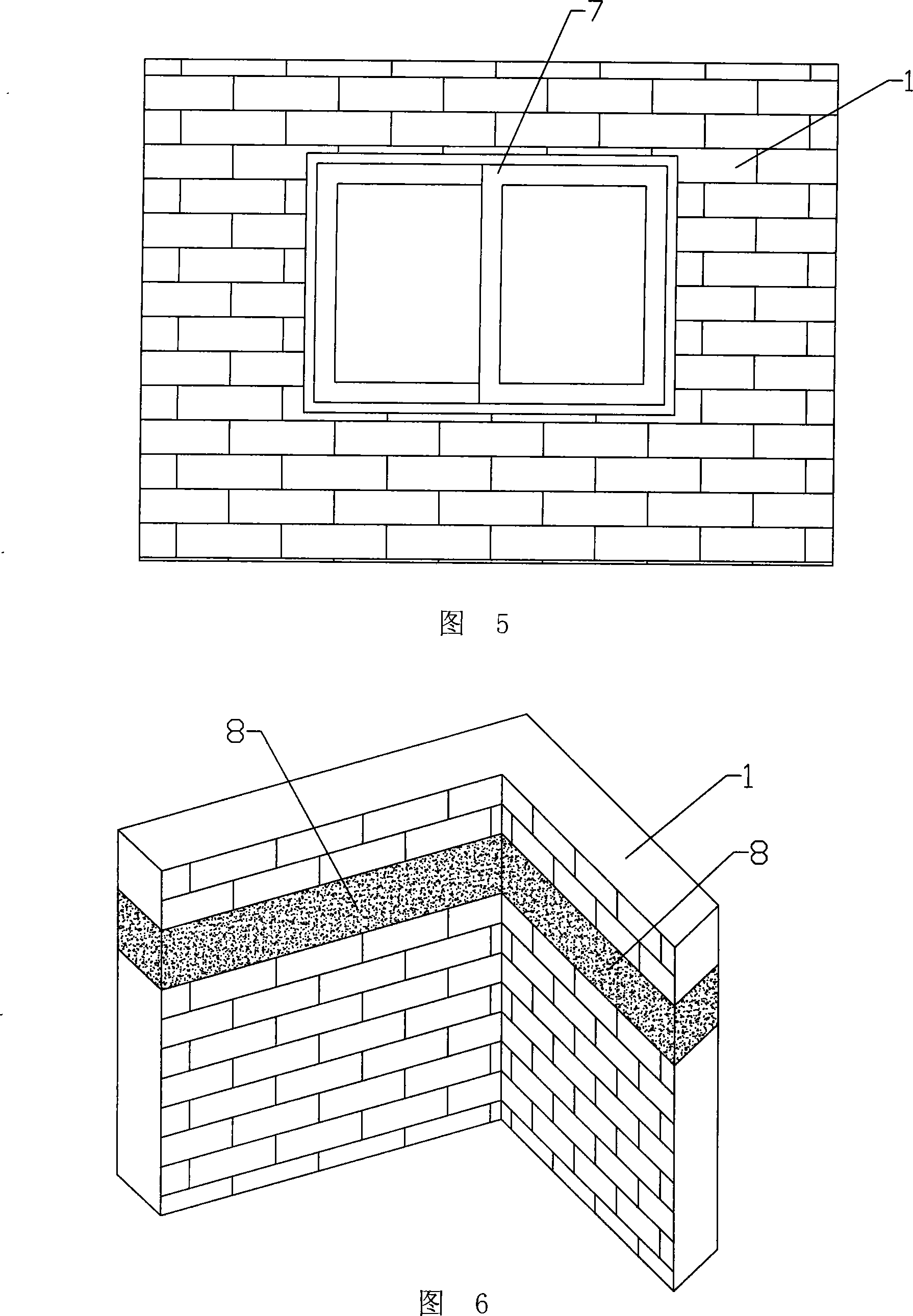

[0033] An embodiment, a construction method for building a house with insulating bricks, the building includes an outer wall 1 made of insulating bricks, an inner wall 2 connected to the outer wall 1, a prefabricated or cast-in-place floor slab 6, metal doors and windows 7 and a concrete ring Beam 8, as shown in Figure 7, said thermal insulation brick includes three parts: concrete load-bearing area 11, EPS thermal insulation layer 12 and concrete protection layer 13, in order to make the connection between the three parts tight, set the dovetail groove that cooperates with each other, the brick It has the advantages of high masonry strength and good thermal insulation effect. As shown in Figure 8, a concrete structural column 3 is provided between the outer wall 1 and the inner wall 2. The construction method of the concrete structural column 3 is to place the concrete structural column 3 inward The wall 2 is extended in the direction to form an extension 18, and an insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com