Fabricated concrete insulation board and non-thermal-bridge strengthening connecting joint thereof

A technology for strengthening connection and insulation board, applied in the direction of insulation, building components, walls, etc., can solve the problems of high energy consumption, air pollution, and the insulation effect cannot be maintained in a good state for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

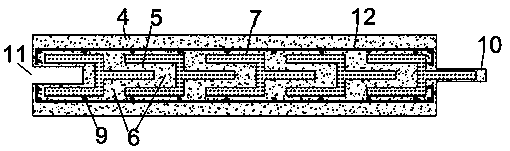

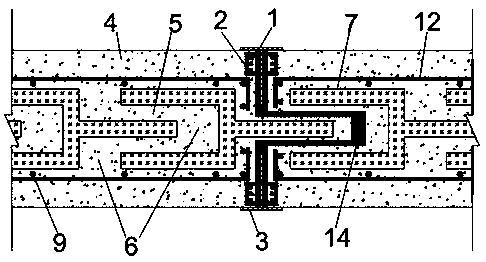

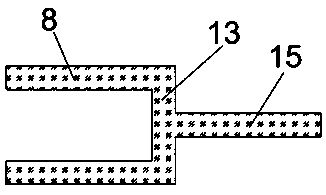

[0022] A prefabricated concrete insulation board and its non-thermal bridge reinforced connection node, including connection reinforced longitudinal reinforcement 1, ring hoop 2, T-shaped steel 3, concrete outer layer 4, concrete intermediate layer 5, concrete rib 6, sandwich insulation Plate 7, thermal insulation sub-board one 8, longitudinal reinforcement 9, convex part 10, concave part 11, reinforced connecting steel bar 12, thermal insulation connection plate 13, thermal insulation bonding mortar 14, thermal insulation sub-board two 15, sub-insulation board one 16 and sub-insulation Board 2 17, in the prefabricated concrete insulation board and its non-thermal bridge reinforced connection node, the sandwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com