Cold air radiating system and method for hot working face of deep mine

A technology for working face and deep well, which is used in mine/tunnel ventilation, earth-moving drilling, household refrigeration devices, etc., can solve the problems affecting the cooling and heat transfer effect of working face, temperature and humidity, etc., to improve efficiency and reduce temperature. and humidity, improve the effect of cooling and dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

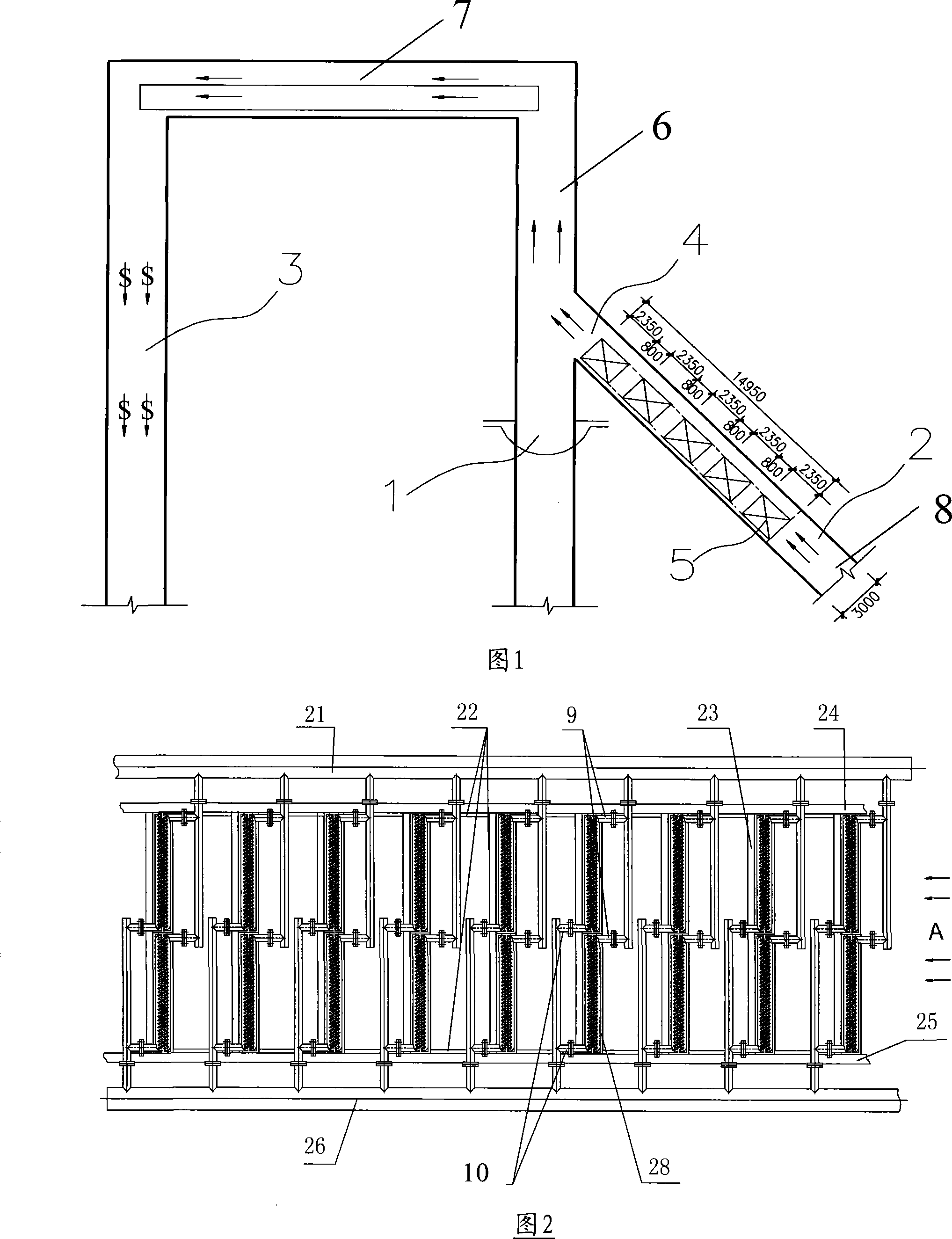

[0023] As shown in Figure 1, this embodiment provides a cold air cooling system for a high-temperature working face in a deep well, which specifically includes:

[0024] Set damper 1 at the air inlet of slot 6 on the working surface of the deep well, set cooling special roadway 2 on the side of slot 6 on the upper side, the air outlet 4 of the special cooling roadway is connected with slot 6 on the upper side, and set the cooling terminal in the special cooling roadway 2 Equipment 5, the air inlet 8 of the cooling special roadway is connected with the air inlet uphill.

[0025] Wherein, the cooling terminal equipment described in the above system adopts a modular cooling device, as shown in Figure 2, the modular cooling device includes: a main water inlet pipe 26, a main return water pipe 21, a frame and at least one cooling structure module 28; The cooling structure module 28 is arranged on the frame, the water inlet pipe 10 of the cooling structure module 28 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com