Accurate mechanical bearing and aerostatic bearing associated shafting

An aerostatic bearing and precision machinery technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of single function and difficulty in realizing ultra-precision machining in the purification room, and achieve improved rotation accuracy, low friction, and precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

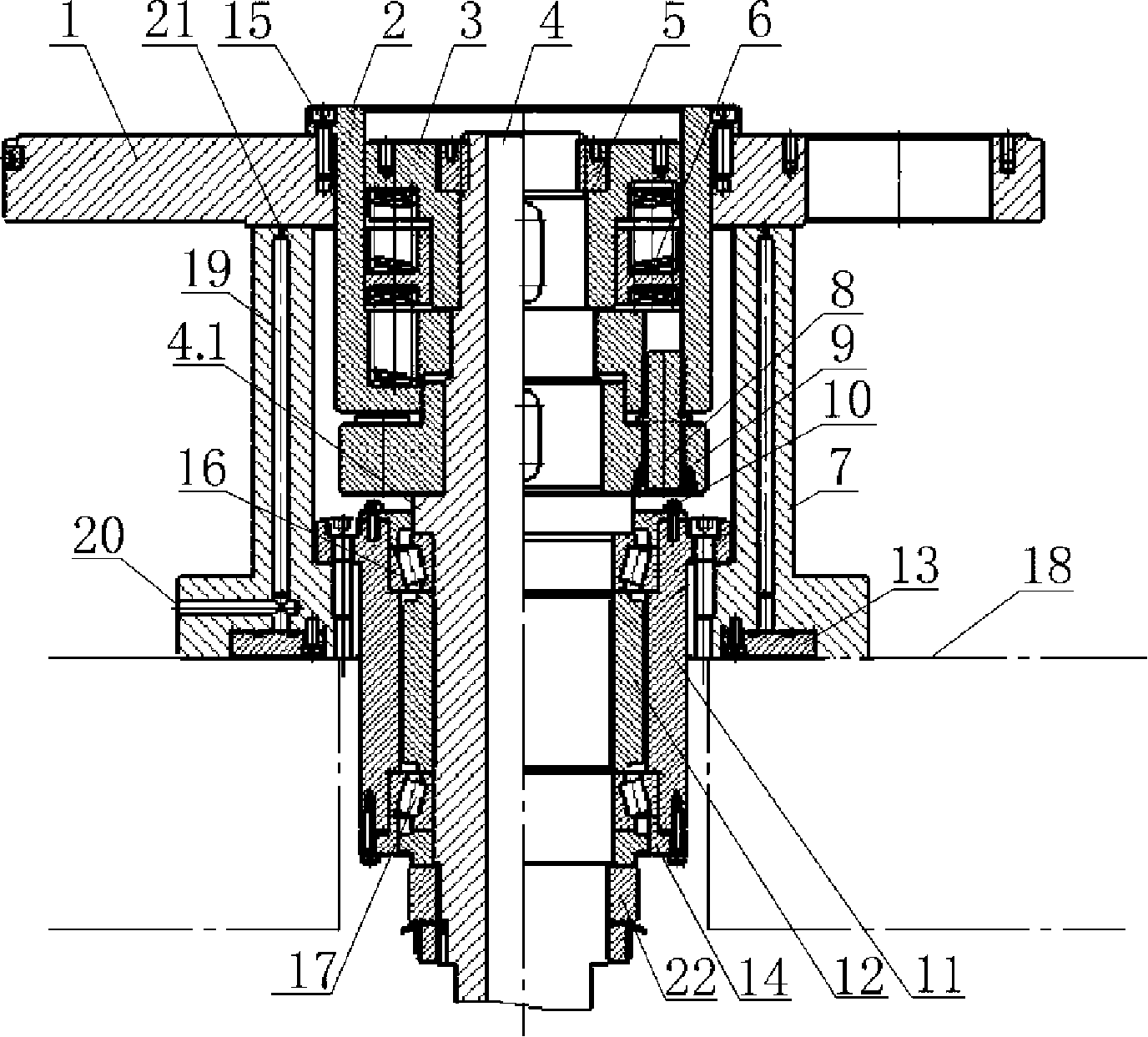

[0019] Examples see figure 1 As shown, this precision mechanical bearing and aerostatic bearing joint shaft system include an upper bearing 16 and a lower bearing 17 connected to the main shaft. The upper bearing 16 and the lower bearing 17 can be precision roller bearings or precision roller bearings. needle bearing. The main shaft 4 is in the shape of a stepped shaft, and there is a ring of flange 4.1 in the middle. There are three steps with gradually smaller diameters from the flange in the middle of the main shaft to the upper end of the main shaft. The transmission disc 9, the connecting sleeve 2 and the adjustment lock are set sequentially from bottom to top. Sleeve 3, transmission disc 9 and connecting sleeve 2 are fixedly connected by pin 8 in the longitudinal direction, connecting sleeve 2 passes through workbench 1, and is fixed with worktable surface by pin 15, and adjusting lock sleeve 3 is connected between main shaft 4 and connecting sleeve 2, the inner ring of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com