Virtual rolling simulation method of hot tandem rolling strip steel

A simulation method, hot rolling technology, applied in the field of hot-rolled strip rolling, can solve problems affecting the accuracy of strip steel, rolling equipment over limit, tracking instability, etc., to improve control quality and precision, and improve design quality , The effect of shortening the debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

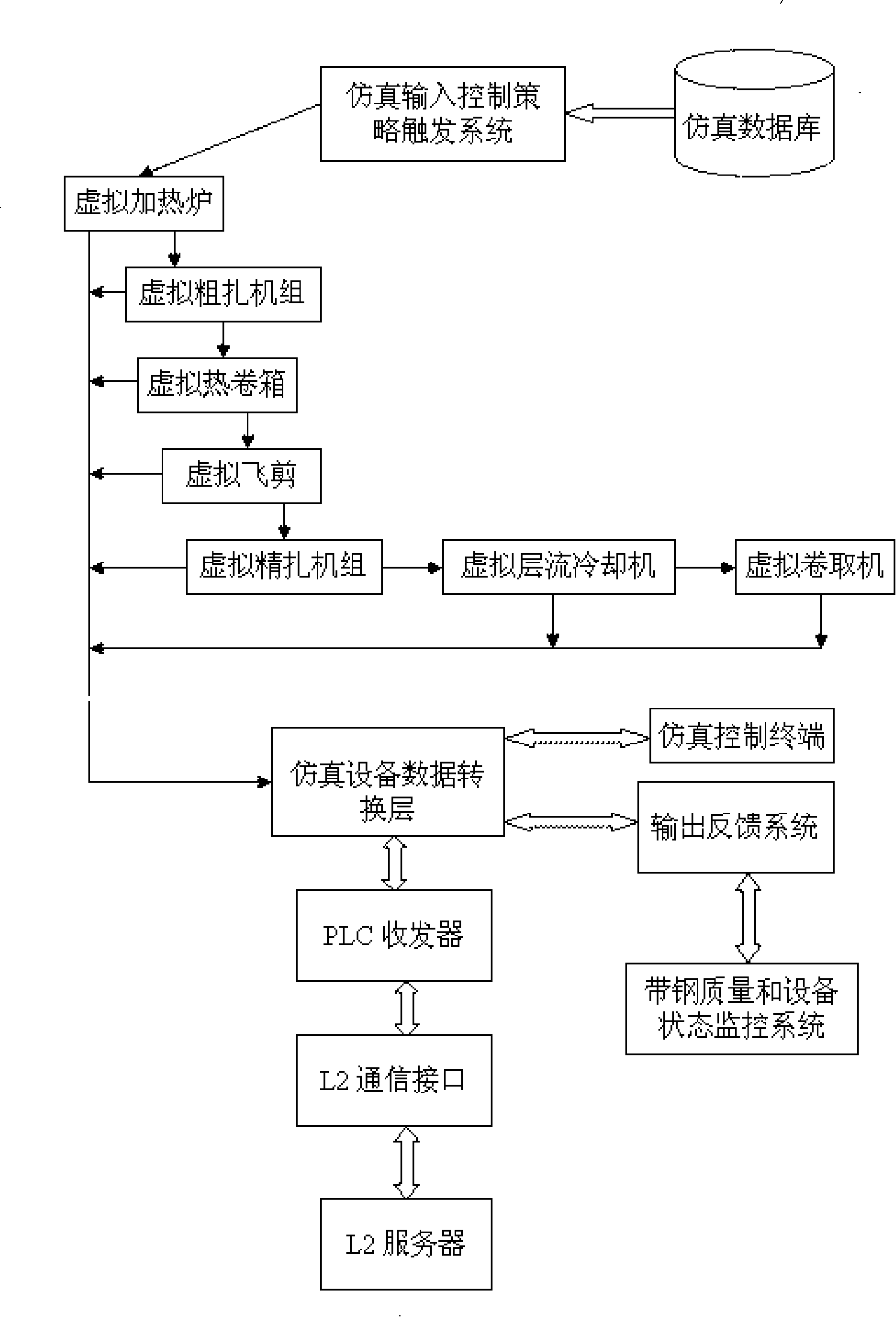

[0022] Starting from the steel rolling process, through mathematical modeling of the steel rolling process, the main equipment parameters of each link in the hot-rolled strip rolling process, rolling steel performance indicators, operating principles, rolling power consumption, wear status, etc., are extracted using OPENGL 3D The model builds the underlying soft environment of the hot rolling site, uses the ROSE modeling tool to build a software simulation support platform, intuitively and quickly reproduces the steel rolling scene and the status of each equipment during the strip rolling process and the change of strip data, realizes the visual simulation of the rolling process, and provides simulation Manually input the foreground and strip data intervention items, and dynamically adjust the strip rolling rhythm and equipment abnormal state, the rolling process of strip steel under different equipment working conditions and time sequences can be simulated. The simulation supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com