Label type polymer base ESD protection device and manufacturing method thereof

A polymer-based, patch-type technology, applied in the direction of electric solid devices, semiconductor devices, overvoltage protection resistors, etc., can solve the problems of loss, high-speed data transmission data distortion, etc., achieve small leakage current, low turning voltage, The effect of small electrode spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

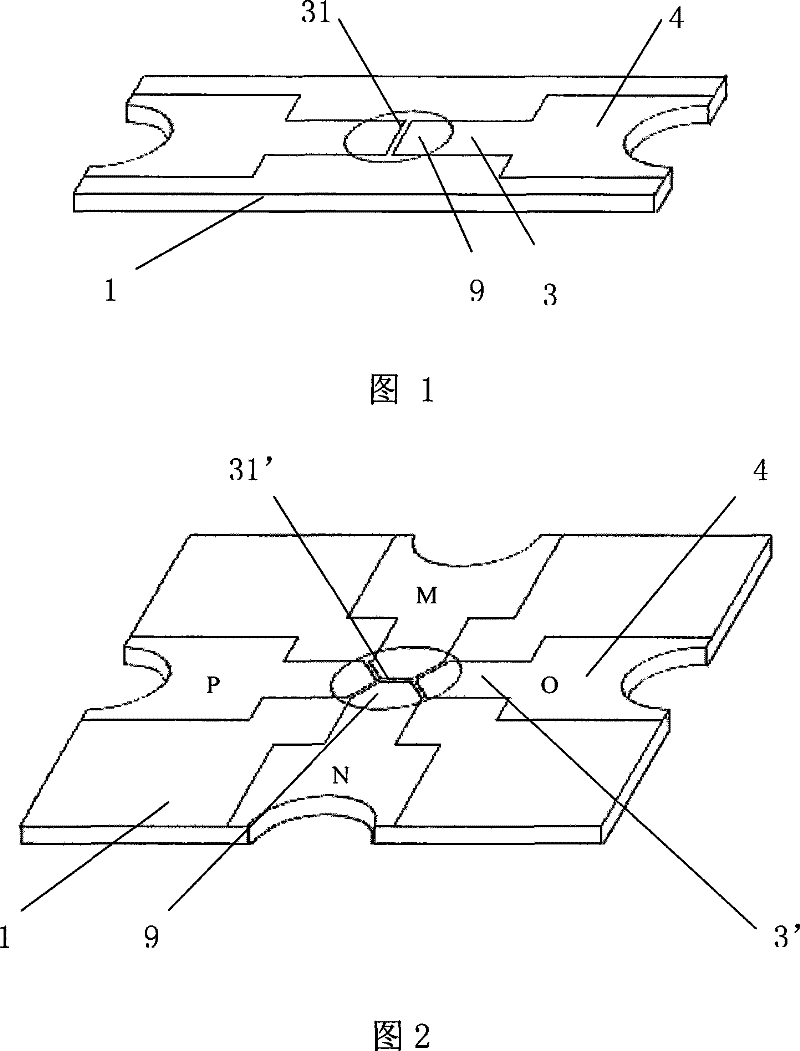

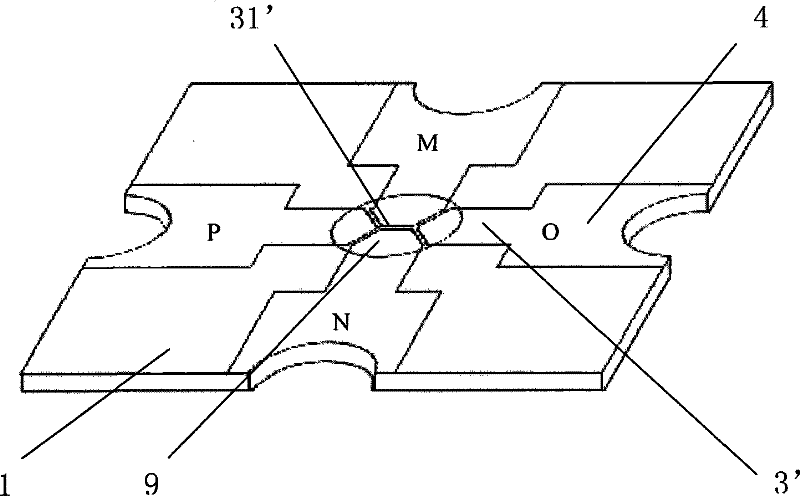

[0044] see figure 1 It is a structural representation of the patch type polymer-based ESD protection device of the present invention, image 3 It is the schematic diagram of the microscopic morphology of the polymer-based ESD protective device core material of the present invention, such as figure 1 , a chip-type polymer-based ESD protection device, including a substrate 1, an internal electrode 3, a core material 2, an end electrode 4 is provided at the end, and the outside is encapsulated by an encapsulation material, wherein the internal electrode 3 is The copper electrode is provided with an electrode groove 31, and the inner electrode 3 is coated with a core material slurry in the coating area 9 according to the design pattern, and the core material slurry is filled in the electrode groove 31, and becomes a core material after curing. 2.

[0045] On the basis of the above solution, the internal electrode 3 is a linear internal electrode, the electrode groove 31 is locat...

Embodiment 2

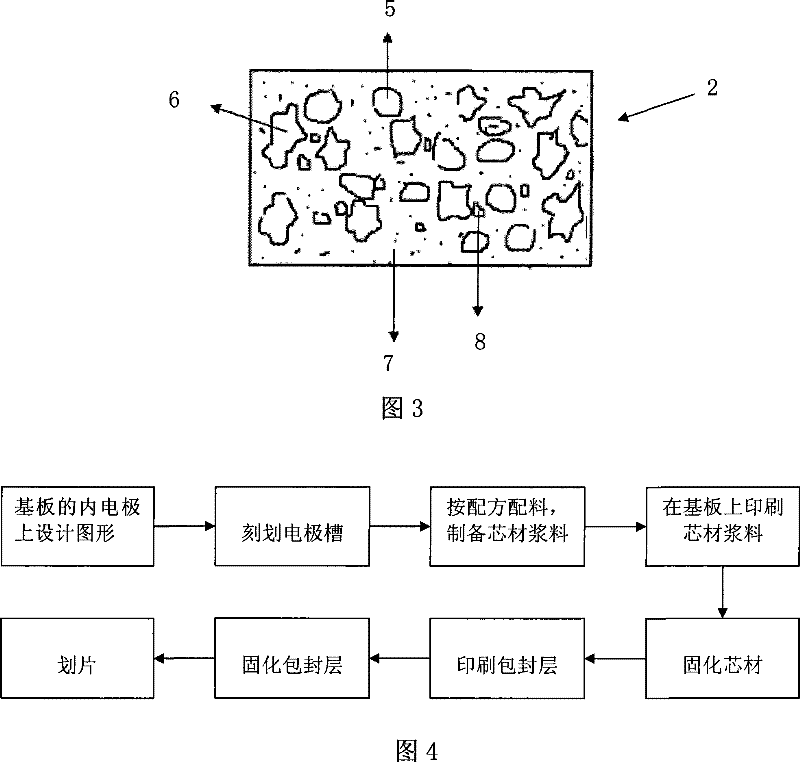

[0060] Others are all the same as in Embodiment 1, except that the structure of the inner electrode and the electrode groove is different, please refer to figure 2 It is another structural schematic diagram of the chip-type polymer-based ESD protection device of the present invention. A chip-type polymer-based ESD protection device includes a substrate 1, an internal electrode 3', a core material, and a terminal electrode 4 at the end. The internal electrode 3' is a cross-shaped internal electrode 3', which has four regions of M, N, P, and O. The electrode groove 31' is located in the middle of the cross-shaped internal electrode 3', which is a ">--<" electrode groove 31' can realize five-way protection of inner electrodes MN, MO, MP, NO and NP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com