Cooling type semiconductor packaging member

A semiconductor and heat-dissipating technology, used in semiconductor devices, semiconductor/solid-state device components, and electric solid-state devices, etc., can solve the problems of waste of precious substrate space, increased cost of molds and heat dissipation structures, and limited configuration of passive components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

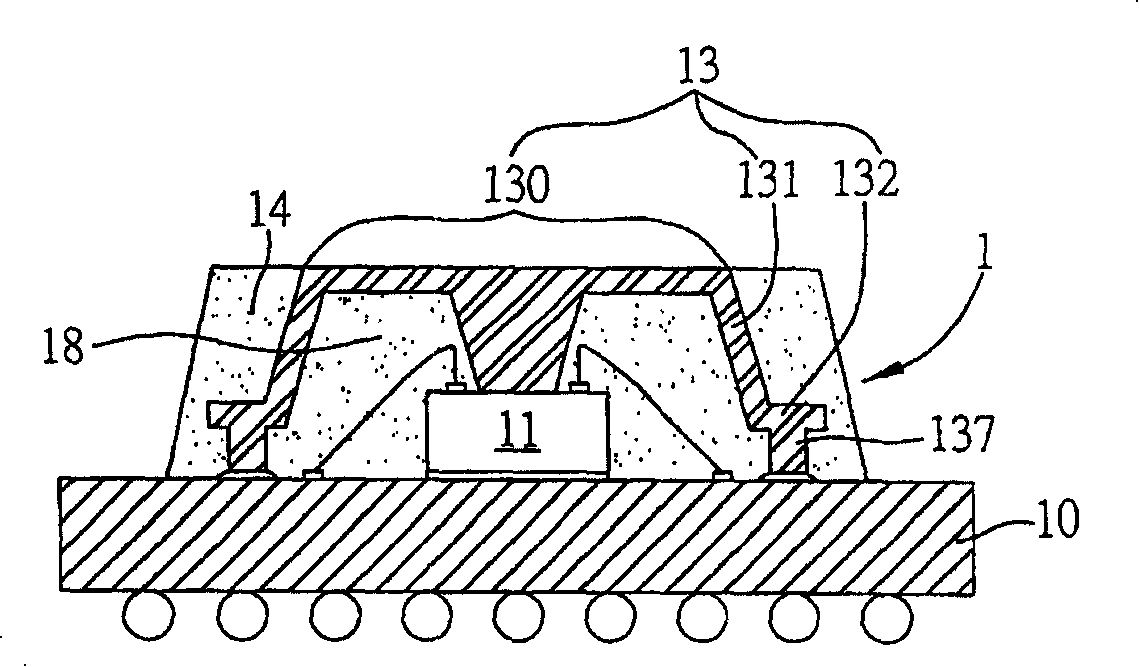

[0063] see Figure 3A and Figure 3B , is a plan view and a schematic cross-sectional view of the first embodiment of the heat dissipation semiconductor package of the present invention.

[0064] As shown in the figure, the heat dissipation semiconductor package includes a substrate 30, the surface of the substrate 30 is provided with a plurality of solder pads 301 and at least one ground pad 302; at least one semiconductor chip 31 is connected to the substrate 30 and electrically connected to the solder pad 301; a plurality of passive components 391 connected to and electrically connected to the substrate pad 301; at least one zero-resistance passive component 392 connected to and electrically connected to the substrate ground pad 302; and a heat sink 32, connected to the passive element 391, and electrically connected to the zero-resistance passive element 392.

[0065] The substrate 30 is, for example, a ball grid array substrate, and a plurality of solder pads 301 and at...

no. 2 example

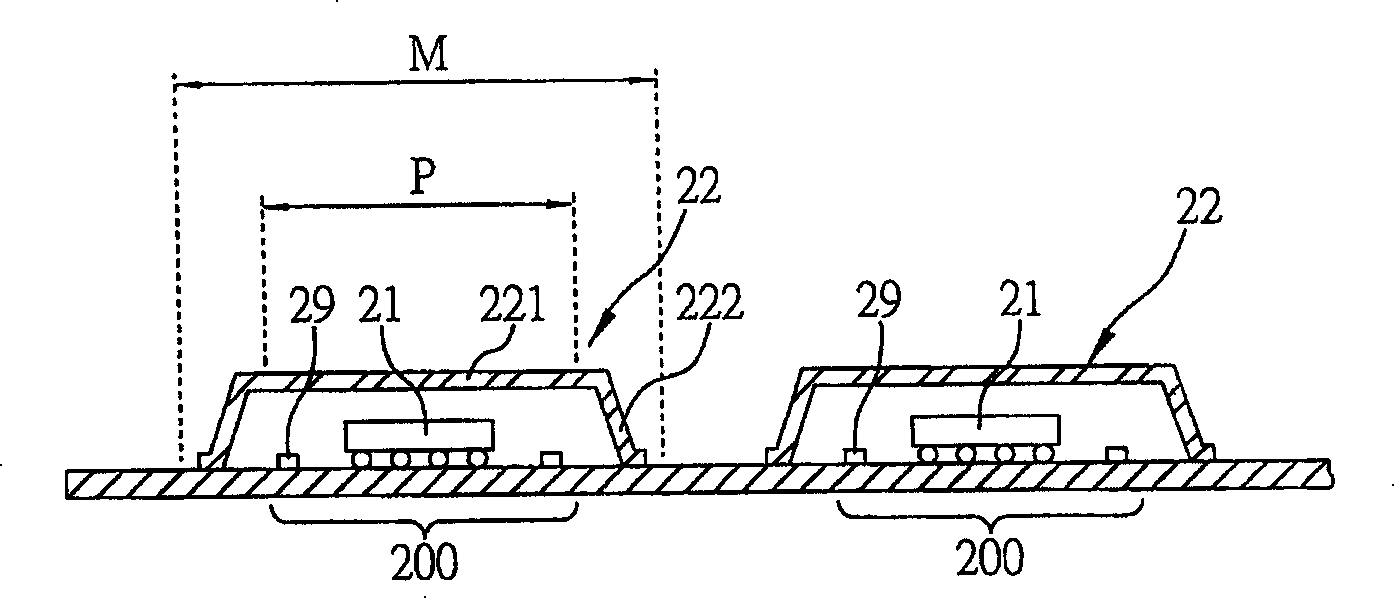

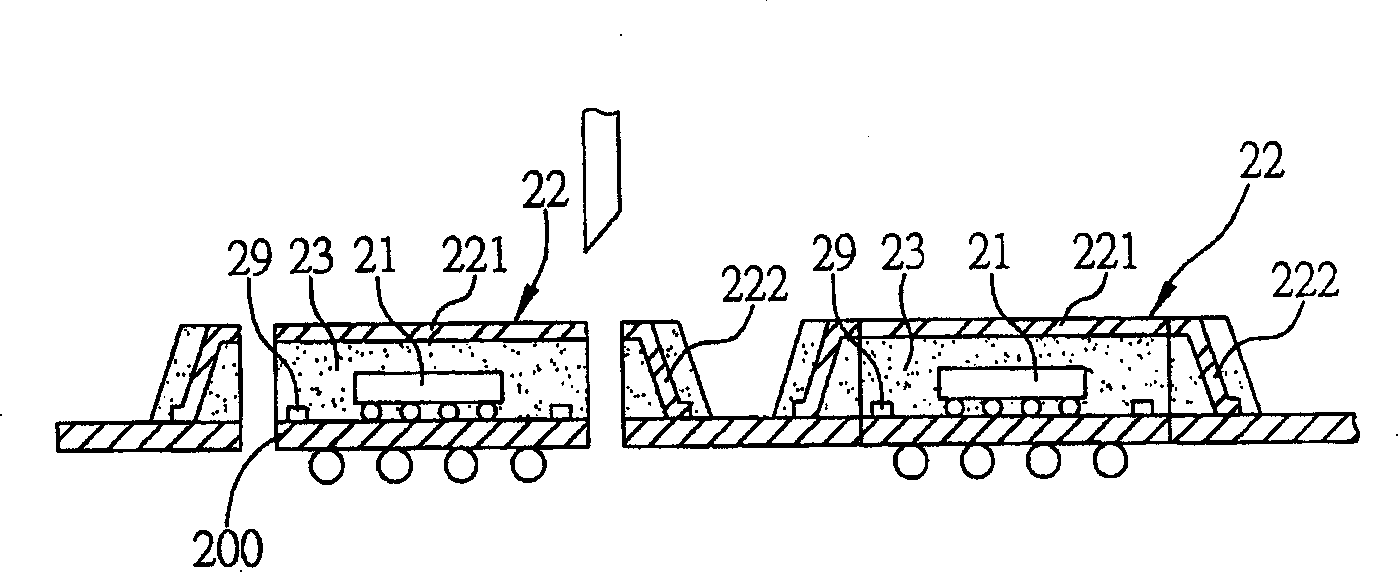

[0075] see Figure 4A to Figure 4C , is a schematic diagram of the second embodiment of the heat dissipation semiconductor package of the present invention, wherein the Figure 4B for correspondence Figure 4A A schematic cross-sectional view of a heat-dissipating semiconductor package.

[0076] What is disclosed in the second embodiment of the heat dissipation semiconductor package of the present invention corresponds to the situation where a general passive element cannot be used as a support structure for a heat sink, or to avoid damage to it, it can be placed at the proximal corner of the substrate 30 (such as Figure 4A and Figure 4B shown) or near the edge (as Figure 4C As shown), a plurality of ground pads 302 are formed, and at least three zero-resistance passive components or metal blocks 38 are placed and electrically connected on the ground pads 302, and at the same time, solder pads 301 are provided on the rest of the substrate 30 for grounding. Place and ele...

no. 3 example

[0078] see Figure 5 , is a schematic diagram of the third embodiment of the heat dissipation semiconductor package of the present invention, the heat dissipation semiconductor package of this embodiment is substantially the same as the previous embodiment, the main difference is that the heat sink 32 can be connected to the heat sink 32 through the thermal conductive adhesive 37 at the same time on the semiconductor chip 31 to enhance the dissipation of heat generated by the semiconductor chip 31 during operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com