Power module cascade connection converter valve

A technology for power modules and converter valves, applied in the field of converter valves, can solve problems such as IGBT import restrictions, and achieve the effects of avoiding tip discharge, convenient power expansion, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

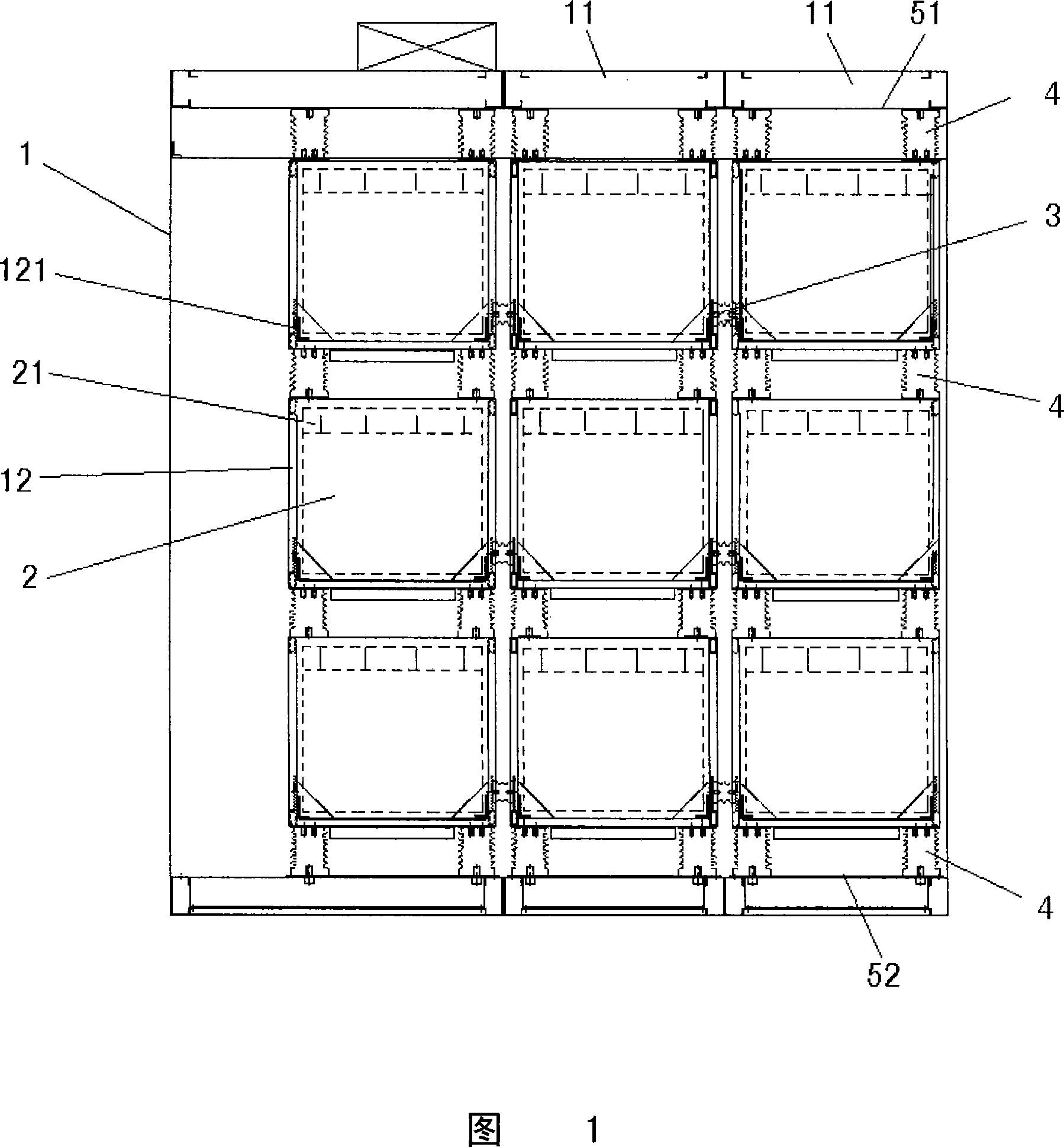

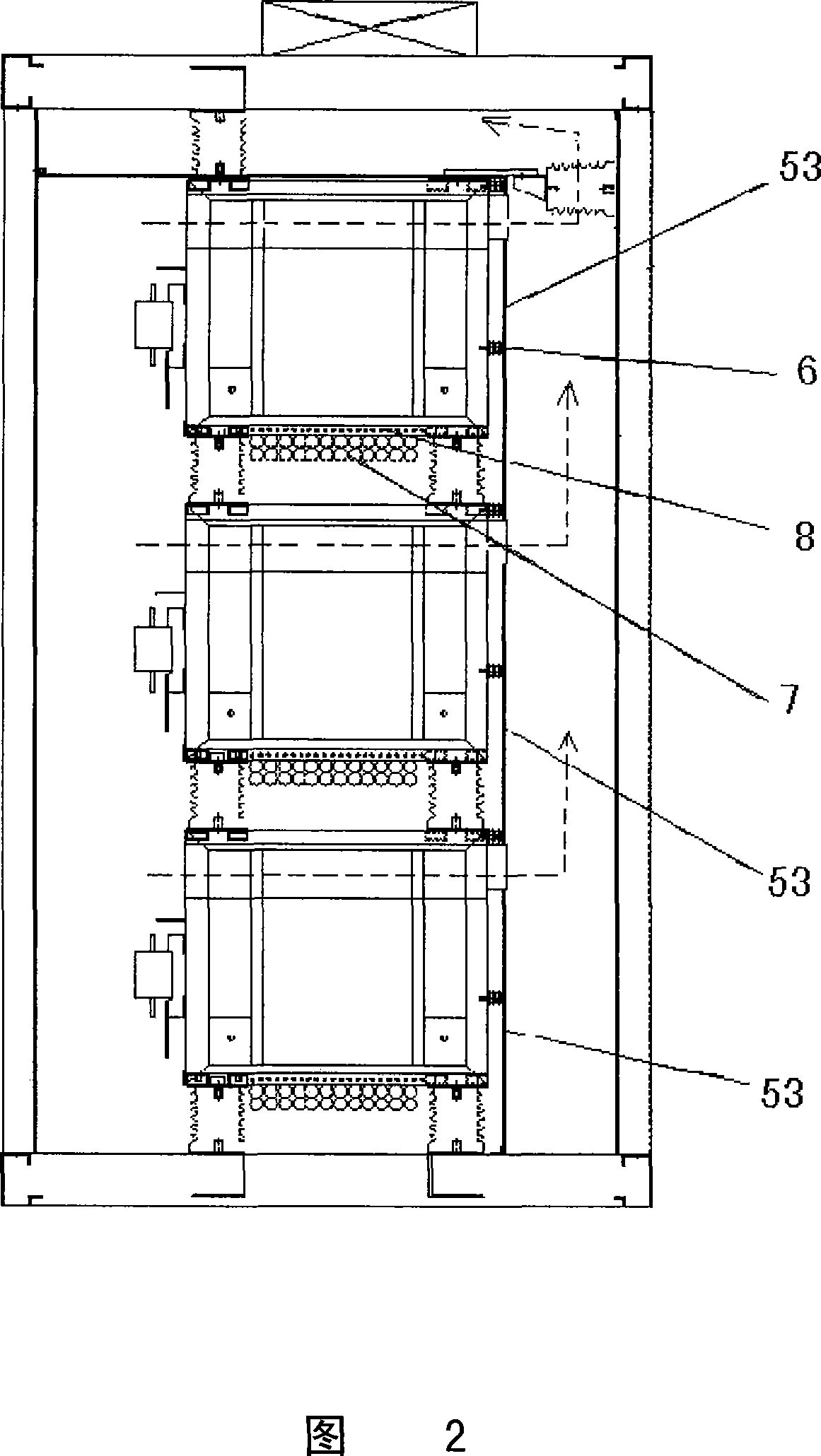

[0011] As shown in Figure 1, the power module cascade converter valve of the present invention includes a cabinet body 1, and the cabinet body 1 is composed of multiple groups of single cabinets 11 connected according to the cascading number of power modules 2, and multiple groups of single cabinets 11 are arranged side by side Placement, from the outside, the individual cabinets 11 are independent, but internally, the individual cabinets 11 are connected. In each single cabinet 11, upper, middle and lower three-layer module frames 12 are arranged. On the two lower corners of each module frame 12, two slide rails 121 are installed. The power module 2 , the power module 2 can slide along the slide rail 121 . The power modules 2 in the upper, middle and lower module frames 12 of the same single cabinet 11 are respectively set to three phases A, B, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com