Energy-efficient sport device

A technology of moving devices and inlets, which is applied in transportation and packaging, electric vehicles, vehicle energy storage, etc., to achieve the effect of reducing impact and changing fluid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

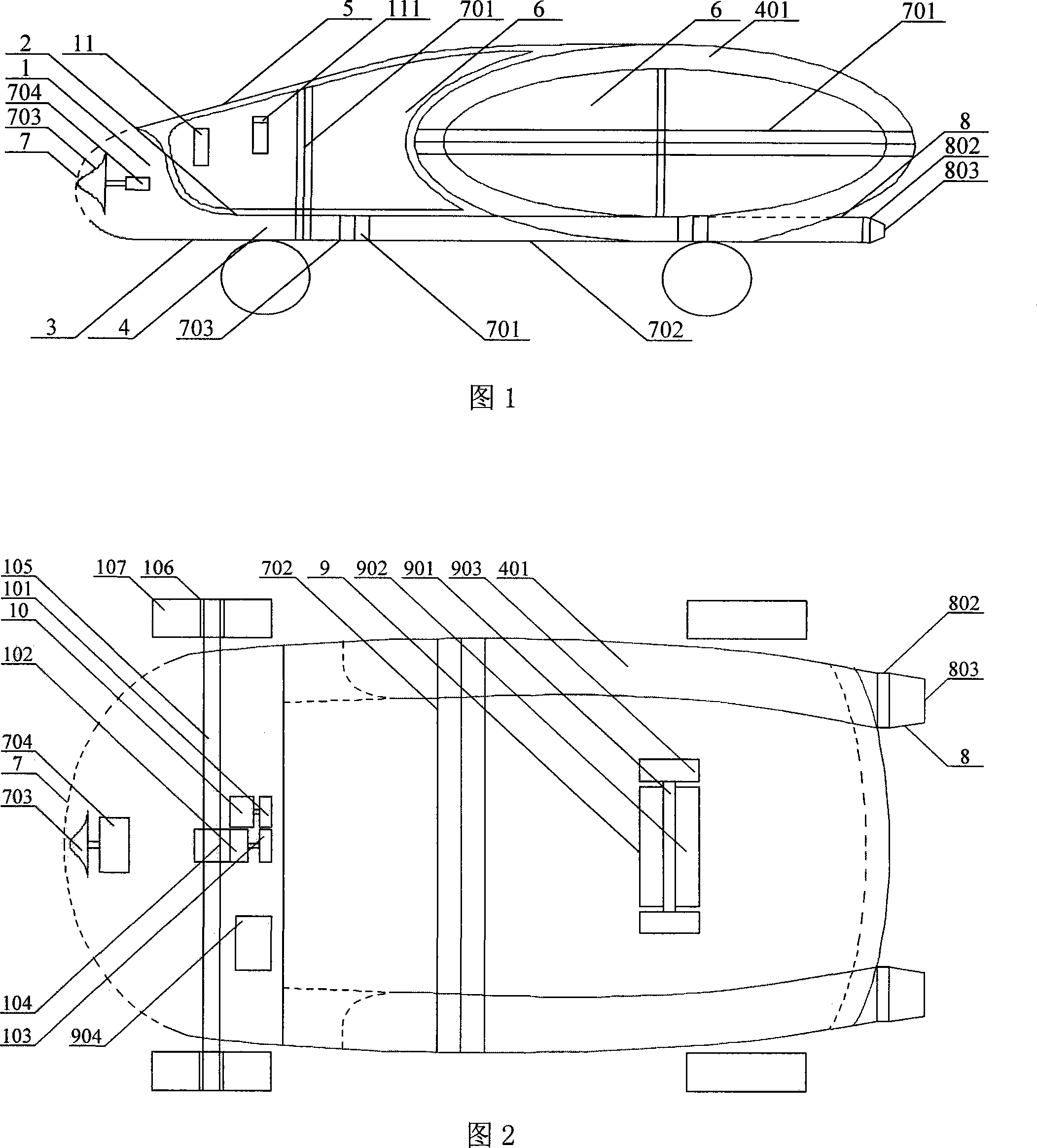

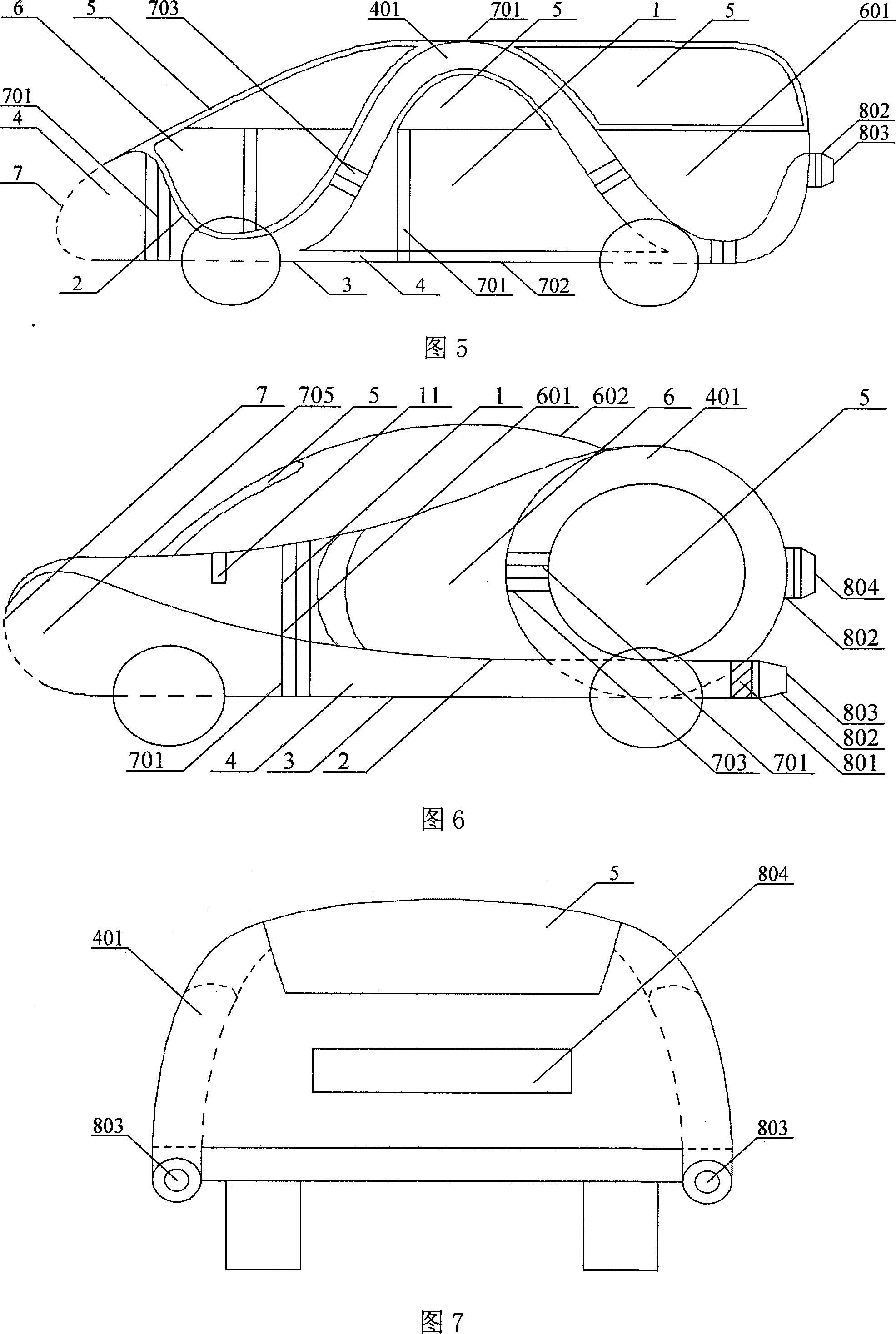

[0028] Embodiment 1, as shown in Figure 1 and Figure 2:

[0029] The front end of the automobile 1 has a fluid inlet 7, which communicates with the fluid layer channel 4 and the two outlets 803 on both sides of the rear. There is a rotating head 703 driven by a motor 704 in the middle of the front-end inlet 7. The shape of the rotating head 703 can be conical, flying saucer-shaped, hemispherical, impeller-shaped, etc., and the rotating head 703 rotates at a high speed. Under the action of centrifugal force, it is convenient for fluid to be introduced into the fluid. In the hole channel 4, on the contact surface between the rotating head 703 and the fluid, there are concave or convex lines to facilitate breaking through the fluid. The fluid layer channel 4 is bent by the channel of metal material to form an elliptical hole as the ring hole 401, and the fluid in the ring hole 401 The outlet 803 is at the lower part of both sides behind the car body, thereby forming the main stru...

Embodiment 2

[0035] Embodiment 2, as shown in Figure 1 Figure 3:

[0036] The difference from Example 1 is that there are three front inlets: 7, 706, and 705, which are completely cut off from front to back by two channel plates 406, and are connected to the inlet, the fluid layer channel, the ring channel and the outlet respectively. Three independent channels, that is, the inlets 706, 402, 405, and 803 are connected, 7, 4, 401, and 804 are connected, and 705, 403, 404, and 803 are connected. The fluid layer channel 4 and the channel structure on both sides of the ring hole 401 are metal Material, the middle channel structure is engineering plastics, wherein the wrinkle line 802 on the guide cylinder 8 can bend the upper, middle and lower angles, so that the fluid can be sprayed to the ground or the fluid hole from the desired angle, and the guide cylinder 8 is equipped with a motor 801 capable of absorbing The function of air and blowing, the inlet 706 on the right side of the front end ...

Embodiment 3

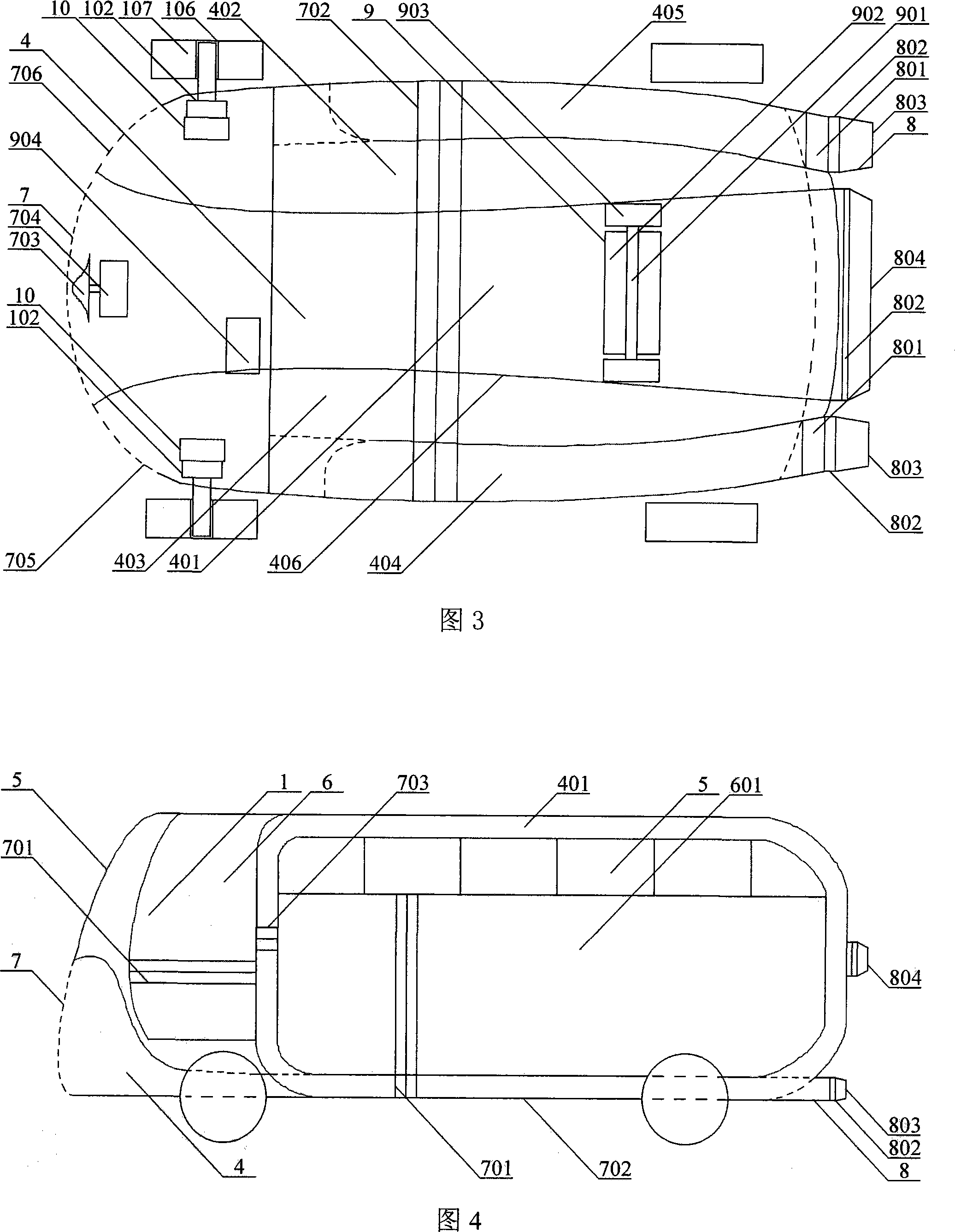

[0038] Embodiment 3, as shown in Figure 4:

[0039] The bus 1 is different from the embodiment 1. Automobile 1 is composed of an inlet 7, a fluid layer channel 4, a ring hole 401 around the automobile shell, a circular outlet 804 in the middle of the rear and two lower outlets 803 on both sides to form the main body of the automobile, and then the front end and the two outlets are installed. The side windshield 5, and the door 6 and the baffle plate 601 are exactly a structure simple and novel and elegant automobile. Wherein the door 6 and the baffle plate 601 are two layers of hollow layers, above which there is an import port 701 to communicate with the ring hole 401, a decorative window 703 is mounted on the import port 701, and the balanced import port 702 at the bottom of the car communicates with the ring hole 401.

[0040] When the automobile 1 is running fast, the fluid wall fluid is introduced into the fluid layer channel 4 from the inlet 7, then passes through the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com