Aluminum reduction cell alumina dense-phase conveying system accurate feeding technique

The technology of conveying system and process method is applied in the field of precise feeding process of alumina dense-phase conveying system of aluminum electrolytic cell, which can solve the problems of material leakage or shortage, increasing the number of feeding times of 2M3 pressure tank, and reducing the physical and chemical indicators of electrolytic cell, etc. Achieve the effect of reducing unit consumption and realizing continuous detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

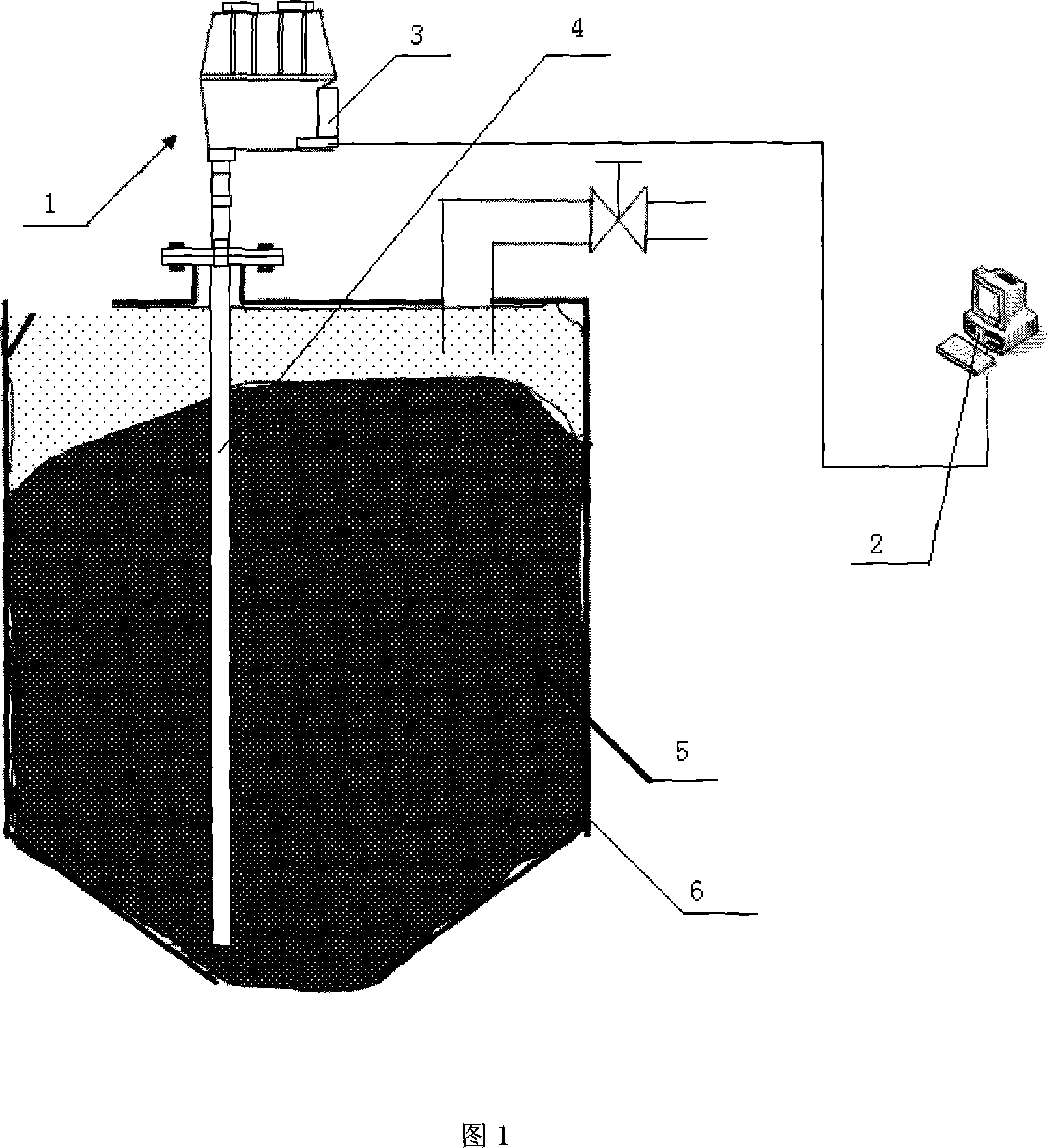

[0022] An aluminum electrolytic cell alumina dense phase conveying system accurate feeding process method includes a continuous level detection device 1 installed on the front and rear bins of the electrolytic cell and a purification automatic control system 2 installed in the workshop monitoring room. The material processing method includes the following steps:

[0023] 1) The real-time detection step of the material level is through the continuous material level measuring device installed on the front and rear bins 6 of the electrolytic tank. 1 The 1.5-meter-long detection rod fixedly installed at the bottom of the electrolytic tank by nuts 4 extends from the top to the bottom of the tank 6 to oppose the electrolytic tank The material level of the tank 6 is detected in real time; when measuring, the 1.5-meter-long probe rod is used as a pole, and the side wall of the electrolytic cell tank 6 parallel to the probe rod is used as a pole; when the material level in the electrolytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com