Method for reduction of temperature during period of building well for deep well coal mine and equipment thereof

A technology for coal mines and deep wells, applied in the field of cooling during well construction, can solve the problems of increasing underground temperature and drainage, equipment can no longer be reused, and expensive cold air station equipment, so as to achieve less cooling loss, reduce underground humidity and drainage, The effect of high cooling conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

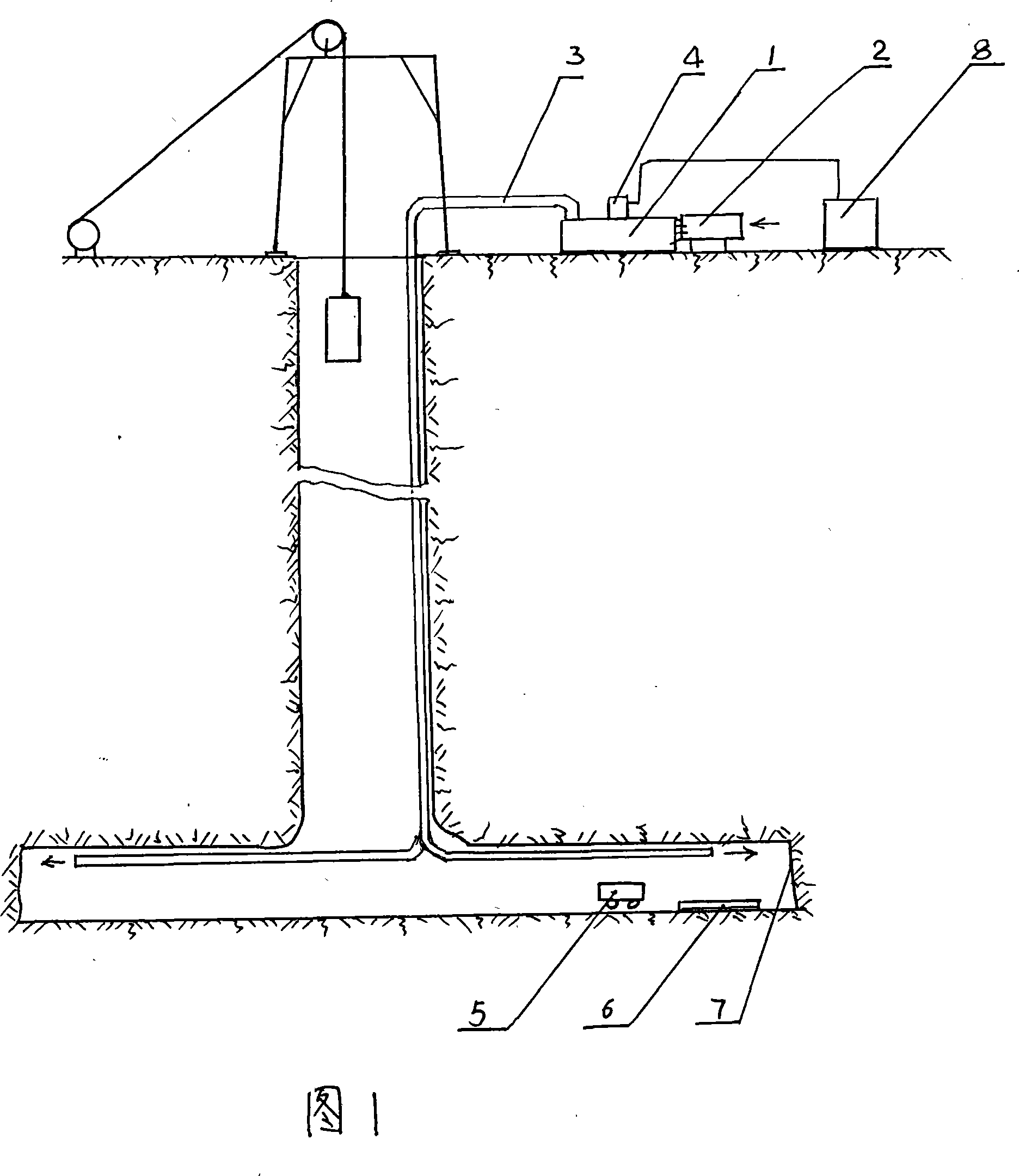

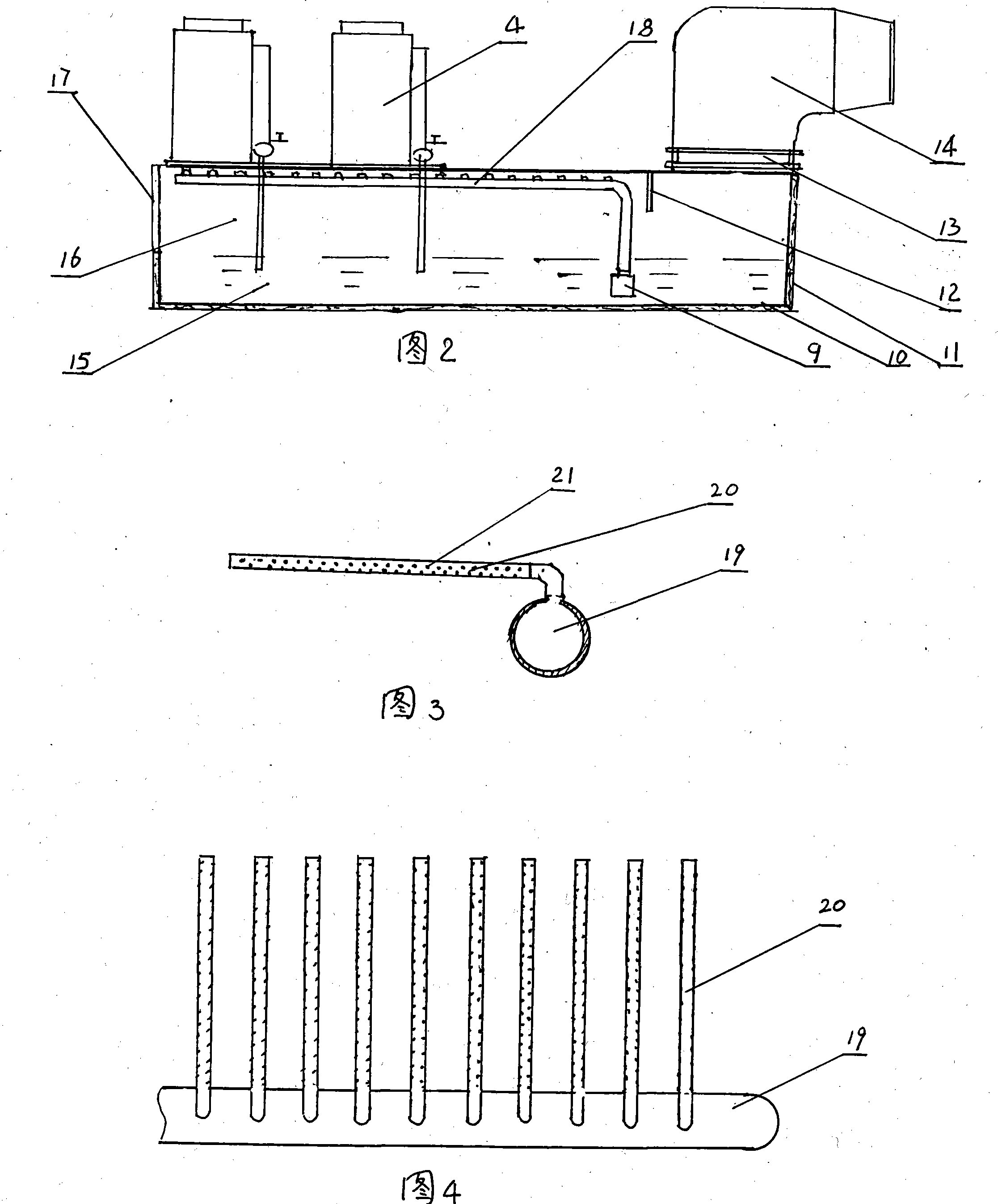

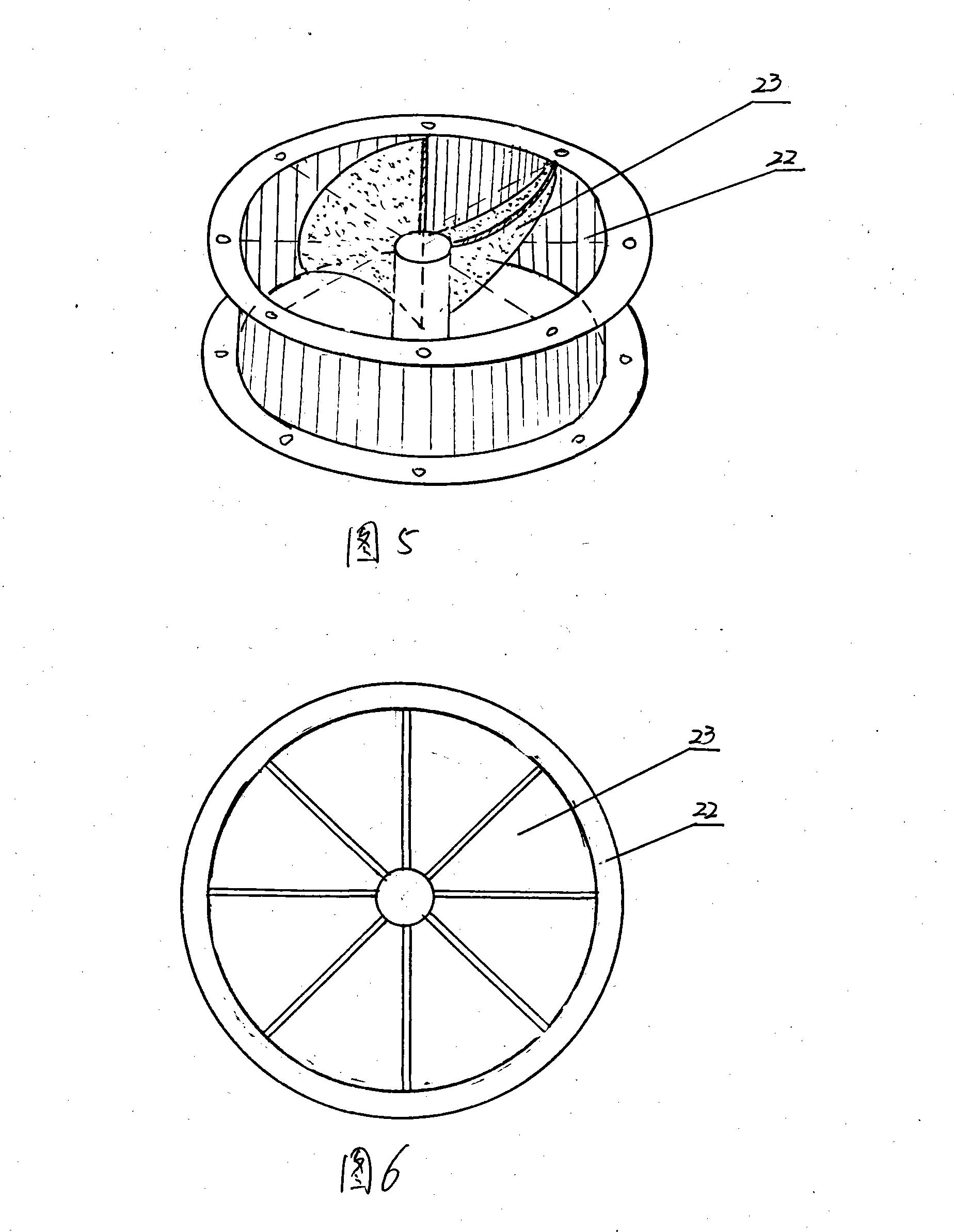

[0027] The present invention will be further described below in conjunction with an embodiment and accompanying drawings.

[0028] Example overview:

[0029] A coal mine has a mining depth of more than 800 meters. When the main and auxiliary shafts are dug, the temperature exceeds 32°C, and the groundwater temperature at the working face exceeds 46°C. After the shaft is dug to the bottom, two roadway working faces need to be constructed at the same time. In order to ensure normal construction, it is necessary to take cooling measures, and it is required to drop below 30°C. After calculation, the required air volume of each working face is 400m 3 / min, the local natural wind temperature needs to be 27°C, and it needs to drop below 21°C before sending it down the well with the air duct to meet the cooling requirements of shaft construction. When the wellbore continues to deepen, 200kg of cooling capacity of -5°C flake ice per hour is needed to meet the cooling requirements.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com