Building pipe built-in joint

A pipeline and construction technology, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve the problems that the water pipes and the punched holes cannot be fully matched, easy to damage the building structure, concrete cracks, etc., to achieve simple structure, Guaranteed strength and convenient pre-embedded construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

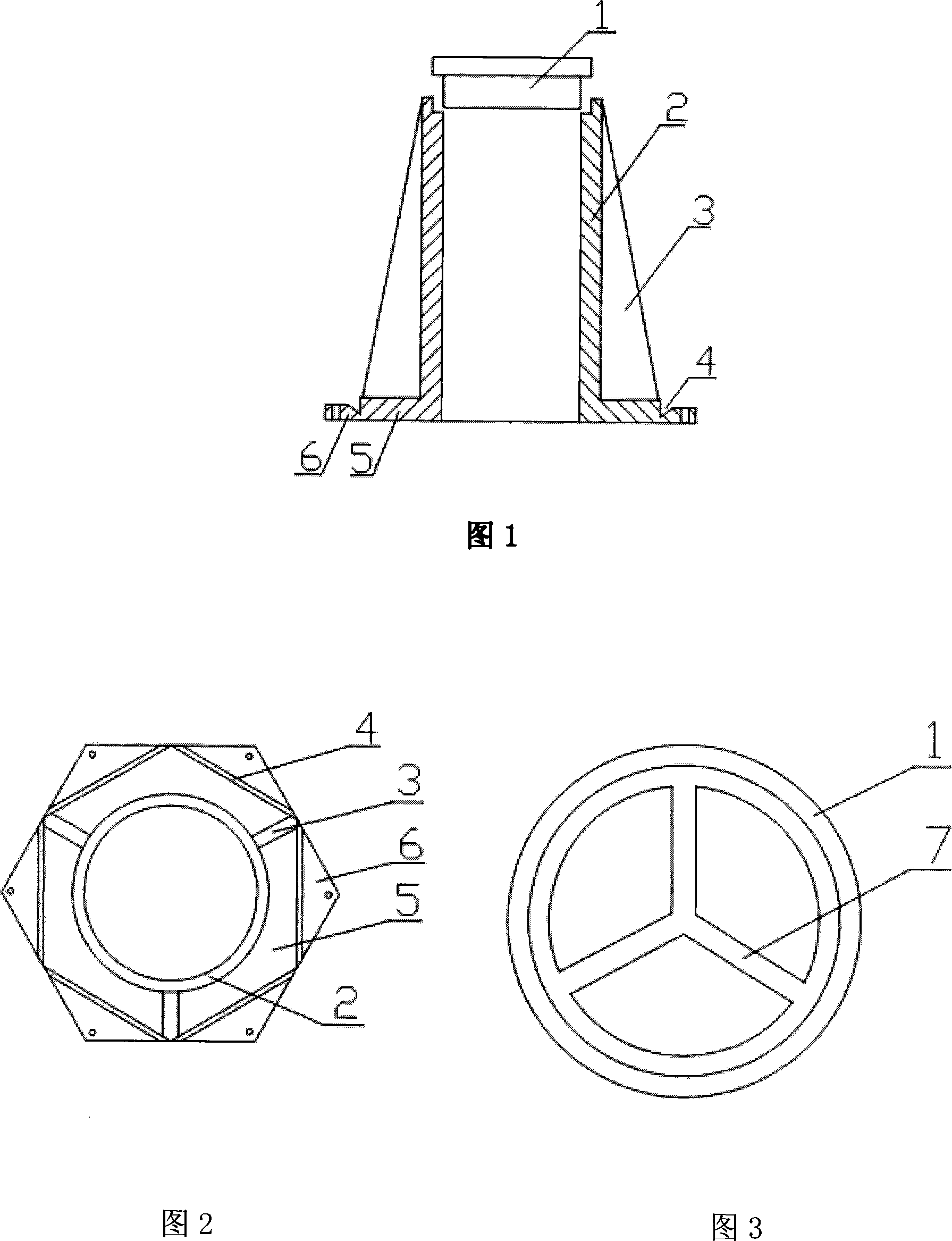

[0010] As shown in FIGS. 1 , 2 and 3 , the pre-embedded joint of the construction pipeline includes a pipe body 2 , a pipe base 5 connected to the lower part of the pipe body 2 , and a pipe cover 1 covering the opening above the pipe body 2 . The pipe body 2 and the pipe base The 5 rooms are connected with reinforcing ribs 3, which play the role of strengthening the structure. The pipe base 5 is also connected with a fixing block 6 , and the connection between the pipe base 5 and the fixing block 6 is slightly thin to form a concave fracture 4 . The fixed block 6 is used to be fixed on the concrete formwork during construction to ensure the accurate position of the joint; when the formwork is dismantled, the formwork fracture 4 is broken, and the fixed block 6 is detached from the pipe base 5 . The tube cover 1 is T-shaped, the outer diameter of the protruding part below it is the same as the inner diameter of the tube body 2 , and the protruding part is hollow, and a tube cap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap