Choke transformer without maintenance

A choke transformer, maintenance-free technology, applied in the direction of variable inductance/transformer, transformer/inductor coil/winding/connection, plastic/resin/wax insulator, etc., can solve the problem of not meeting the requirements of railway signal use, installation and maintenance Inconvenience, poor transmission characteristics and other problems, to reduce the probability of theft, easy installation and maintenance, to ensure the effect of traction current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

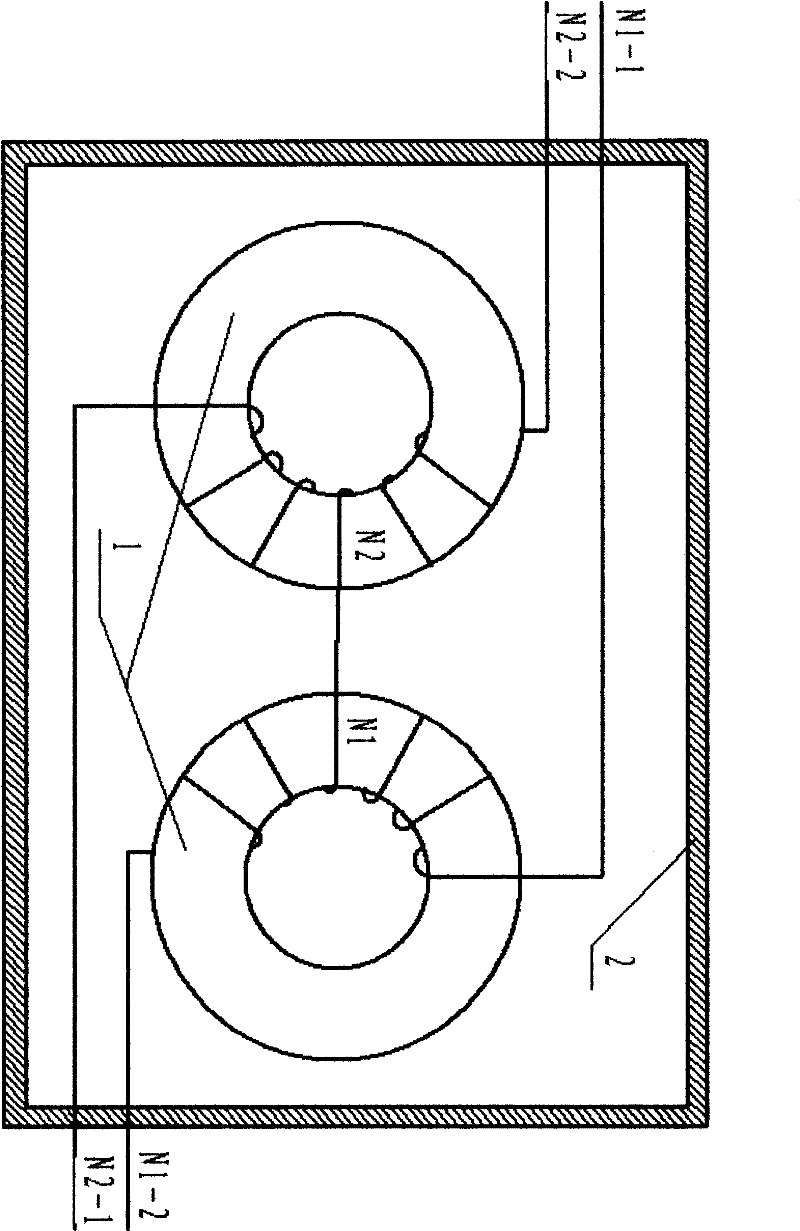

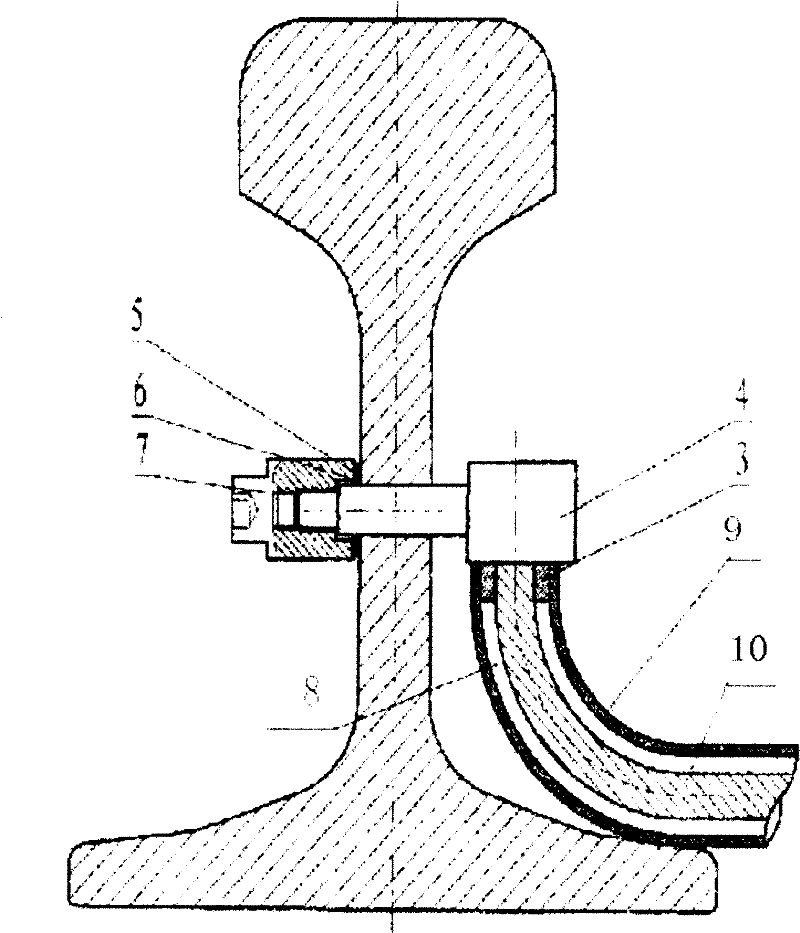

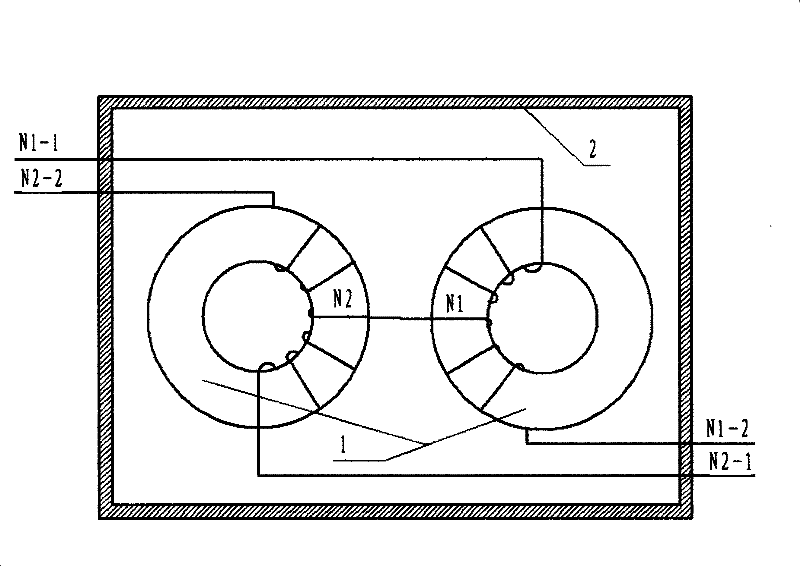

[0013] See attached figure 1 . 1 is the maintenance-free choke transformer core, which can be wound with silicon steel strips. 600-800A maintenance-free choke transformer core section is 45*45mm. 1000A maintenance-free choke transformer core section is 60*60mm. The second is the maintenance-free choke transformer box, which is made of die-cast aluminum, and a fastener is installed at the outlet. See attached figure 2 . 3 is the secondary waterproof welding sheath, using 301 austenitic stainless steel pipe. The 4th, plug nail, use No. 20 steel manufactures. 5 is anti-loosening pad. 6 is the plug screw thread. 7 is the anti-theft nut that maintenance-free choke transformer uses. 8 is an inner layer sheath, which adopts polyethylene material or polyvinyl chloride material. 9 is an outer sheath, which adopts a cross-linked polyethylene material. 10 is a steel-cored aluminum stranded wire, and a 600-800 ampere maintenance-free choke transformer adopts a steel-cored alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com