Bitumen-containing high-quality bitumen and its preparation method

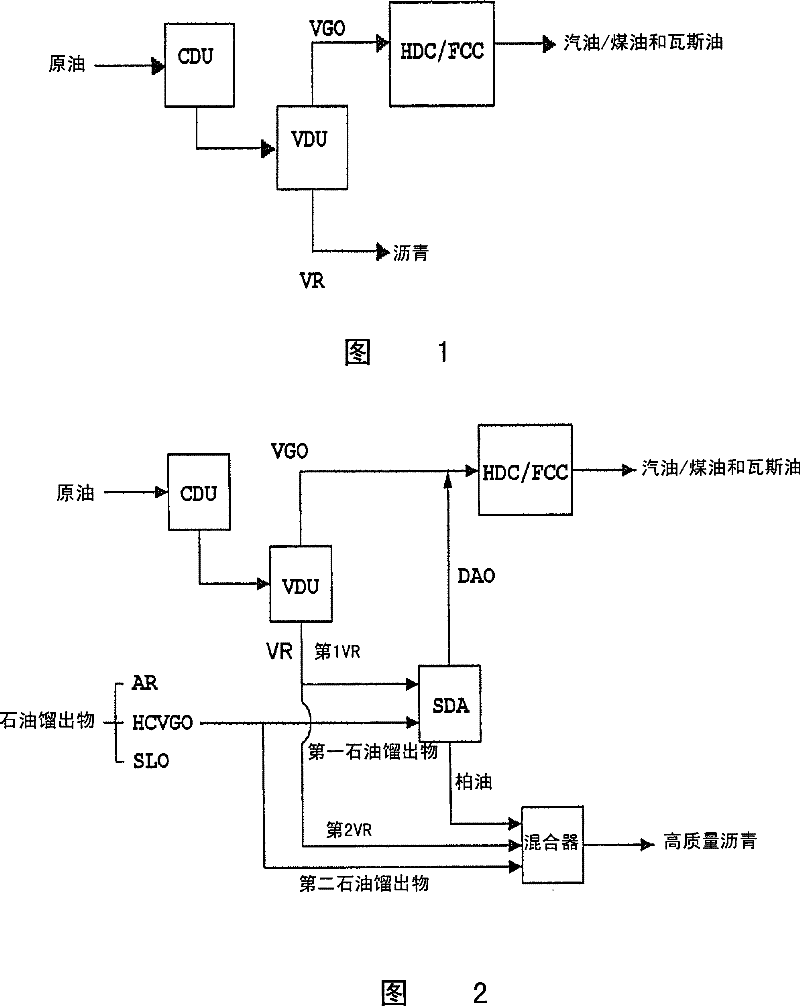

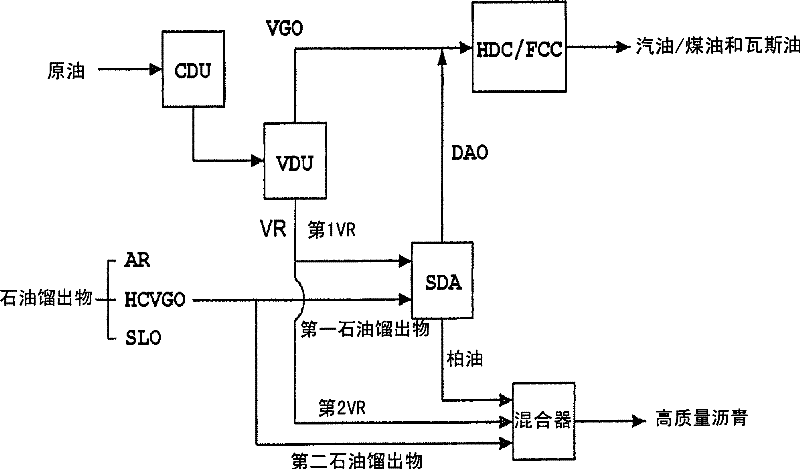

A high-quality, asphalt technology for solvent refining by deasphalting, processing of tar pitch/petroleum pitch/natural pitch, processing of tar pitch/petroleum pitch/natural pitch by mixing fractions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The raw material comprising atmospheric residue (AR) and vacuum residue (VR) having the properties shown in Table 1 mixed at a volume ratio of 18:11 was subjected to solvent deasphalting under the conditions shown in Table 2 below, thereby producing deasphalted oil and asphalt. The results are shown in Table 3 below. In order to control the permeability of the bitumen thus produced, a middle distillate vacuum residue was also added to produce bitumen. The properties of the bitumen thus obtained are shown in Table 4 below.

[0038] As can be clearly seen from Table 4, when using asphalt to prepare asphalt, compared with the conventional asphalt prepared from the vacuum residue produced by using a vacuum distillation device, the asphalt prepared by the present invention has a higher content Aromatics and resins and a lower content of saturated compounds, so high-quality bitumen with low wax content and high ductility after film oven test can be produced. Since the bitu...

Embodiment 2

[0046] The raw material containing atmospheric residue and vacuum residue with the properties shown in Table 1 mixed in a volume ratio of 18:11 was subjected to solvent deasphalting under the conditions shown in Table 5 below to obtain deasphalted oil and asphalt . The results are listed in Table 6 below. The bitumen so produced is blended with vacuum residue and then with middle distillate vacuum residue to control its permeability to produce bitumen. The properties of the bitumen thus obtained are listed in Table 7 below.

[0047] From Table 7 it is evident that bitumens made using asphalt demonstrate better ductility after film oven testing than bitumens made from vacuum residue under the same permeability conditions.

[0048] Table 5 Conditions for solvent deasphalting: 70% asphalt

[0049] Feed AR / VR (18 / 11 volume ratio) solvent propane Asphalt yield, wt% 70 Pressure, kg / cm 2 gram 45.7 Asphaltenes separator temperature 88

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com