Machine tool

A technology of machine tools and processing units, which is applied in the field of machine tools, can solve the problems of machining accuracy limitation, positioning accuracy limitation, no disclosure or suggestion, etc., and achieve the effect of reducing machine weight and load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

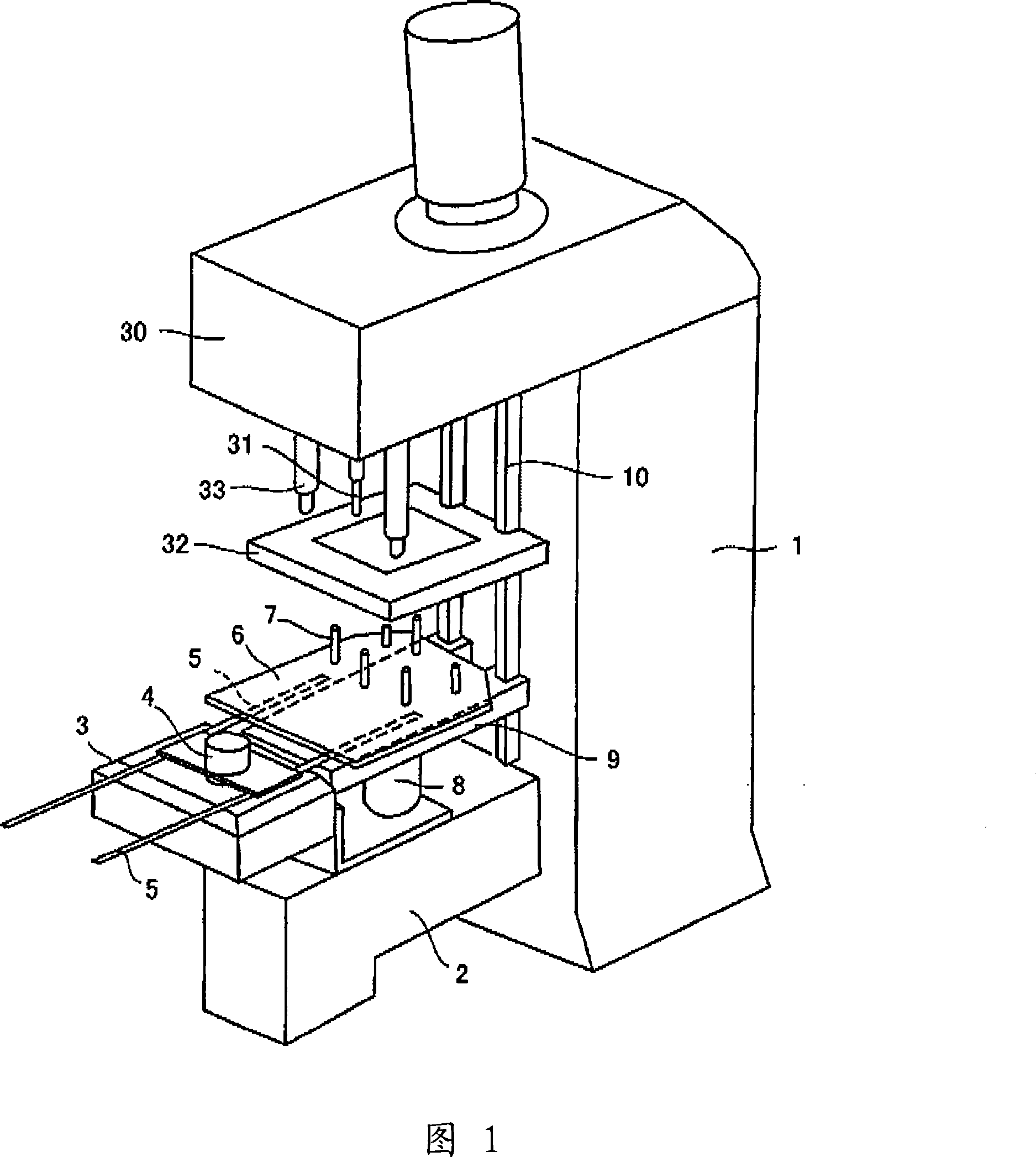

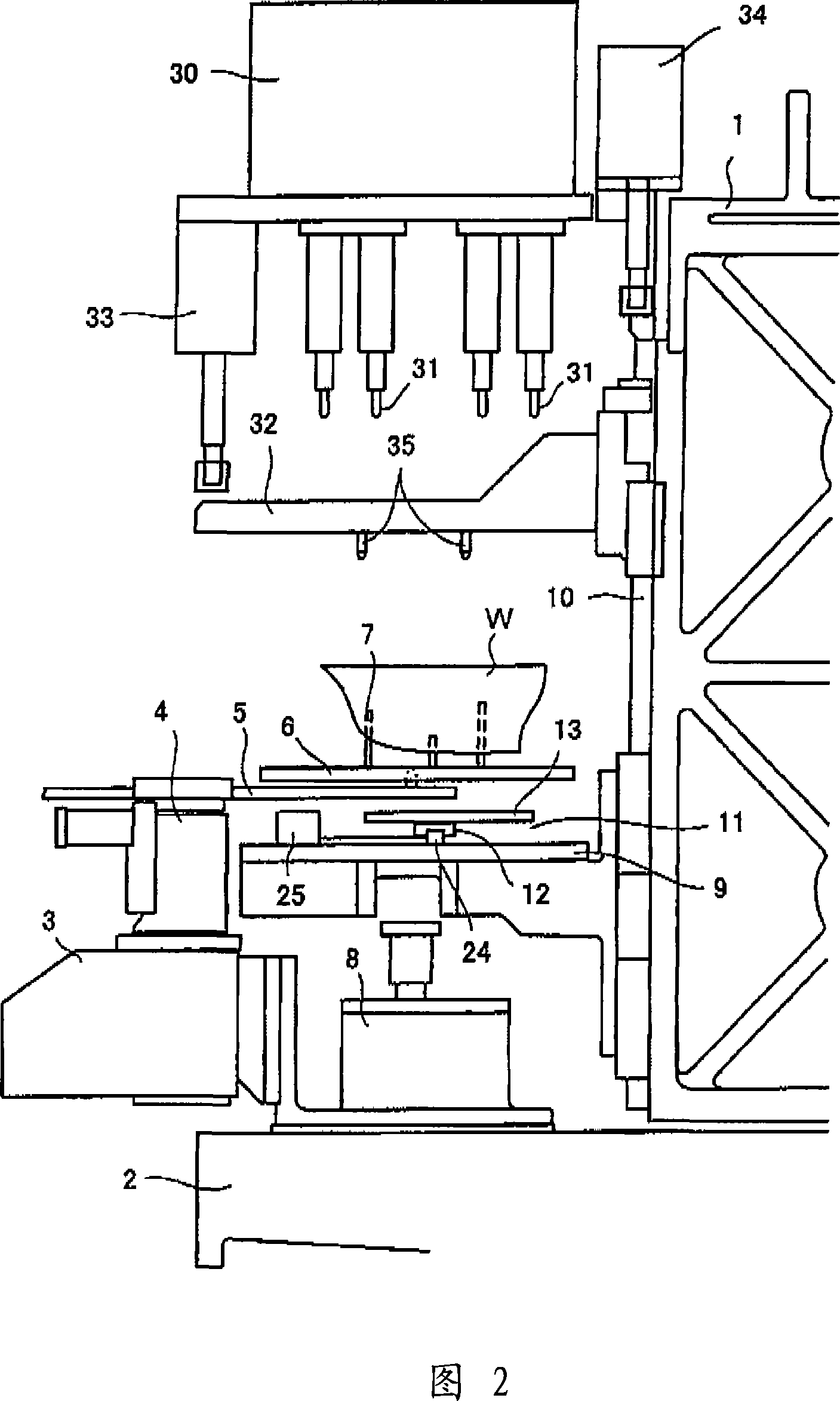

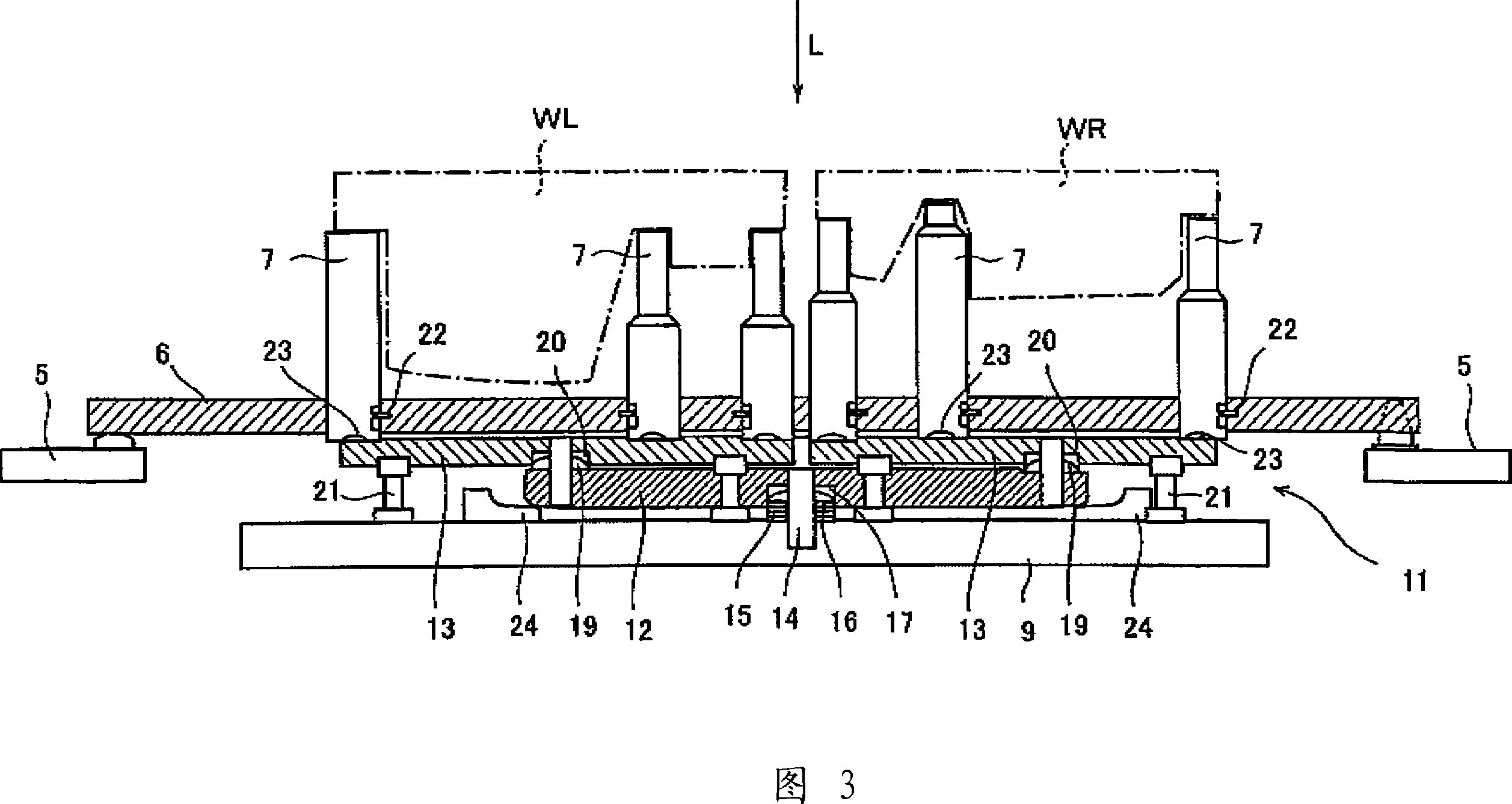

[0030] Illustrative embodiments of the present invention will be explained with reference to the drawings. FIG. 1 is an overall perspective view of a machine tool according to an exemplary embodiment of the present invention. Fig. 2 is a side view of the machine tool in a standby state. Fig. 3 is an enlarged view showing a state where the tray is placed on the bottom plate. Fig. 4 is a front view of the machine tool in a standby state. Fig. 5 is a side view of the machine tool in a processing state. FIG. 6 is a view showing a state where a workpiece is lifted from the position shown in FIG. 5 and then processed.

[0031] In the machine tool, a protruding base portion 2 is provided to a bottom portion of a frame 1 to protrude forward, and a turntable 3 is fitted to an end of the protruding base portion 2 . The respective arms 5, which are out of phase by 180°, are fitted to the shaft 4 of the turntable 3, which shaft 4 is turned by a motor. When the arm 5 is rotated on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com