Chip bonding machine platform and heating plate thereof

A technology of bonding machine and heating plate, which is applied in the direction of conveyor objects, electrical components, electric solid devices, etc., can solve the problems of difficulty in failure analysis work, slow speed, inconvenient rotation, etc., to avoid electrostatic damage to devices, simplify Machine structure, the effect of avoiding bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

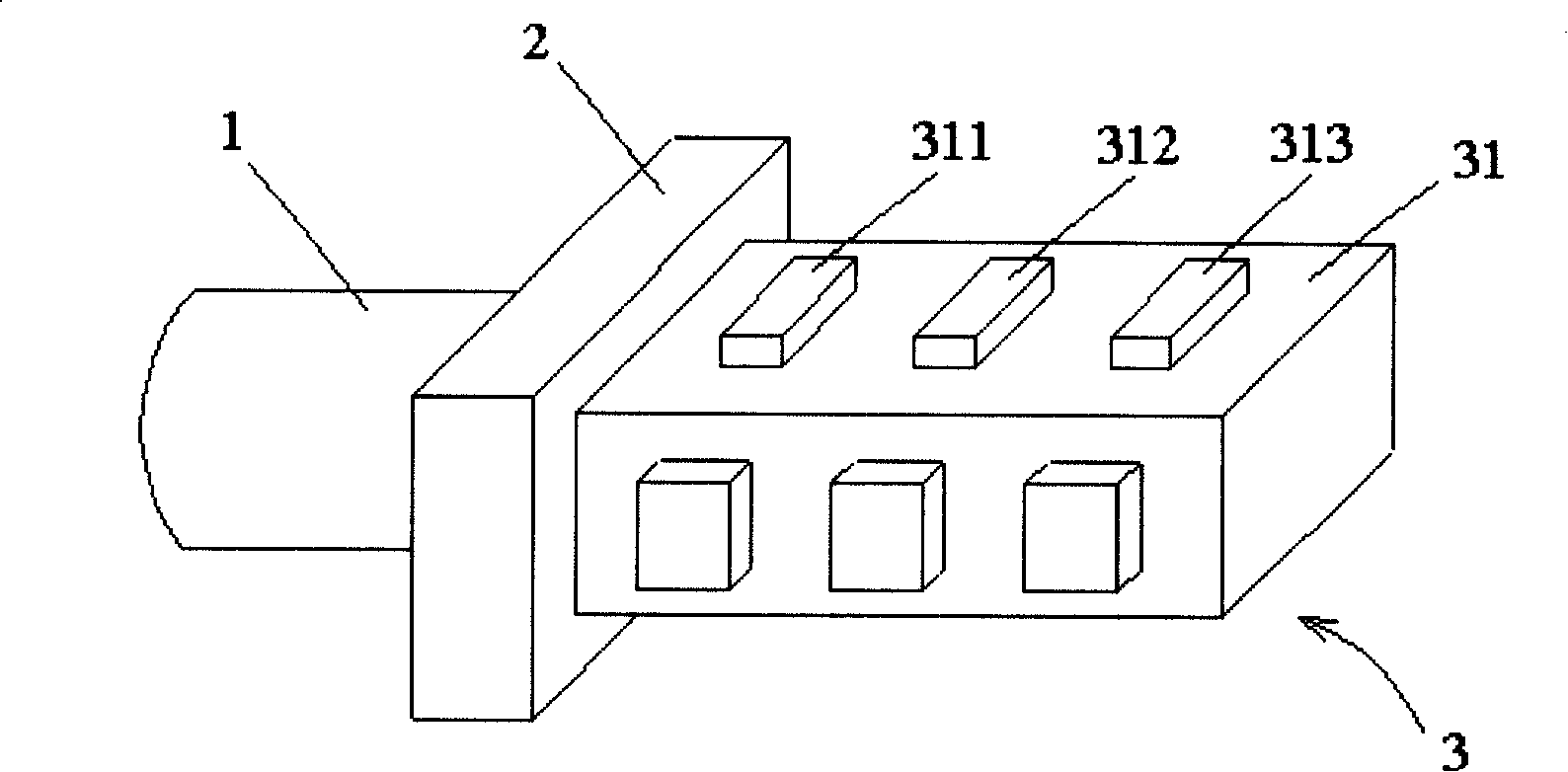

[0030] The chip bonding machine and its heating plate of the present invention will be further described in detail below with reference to the accompanying drawings.

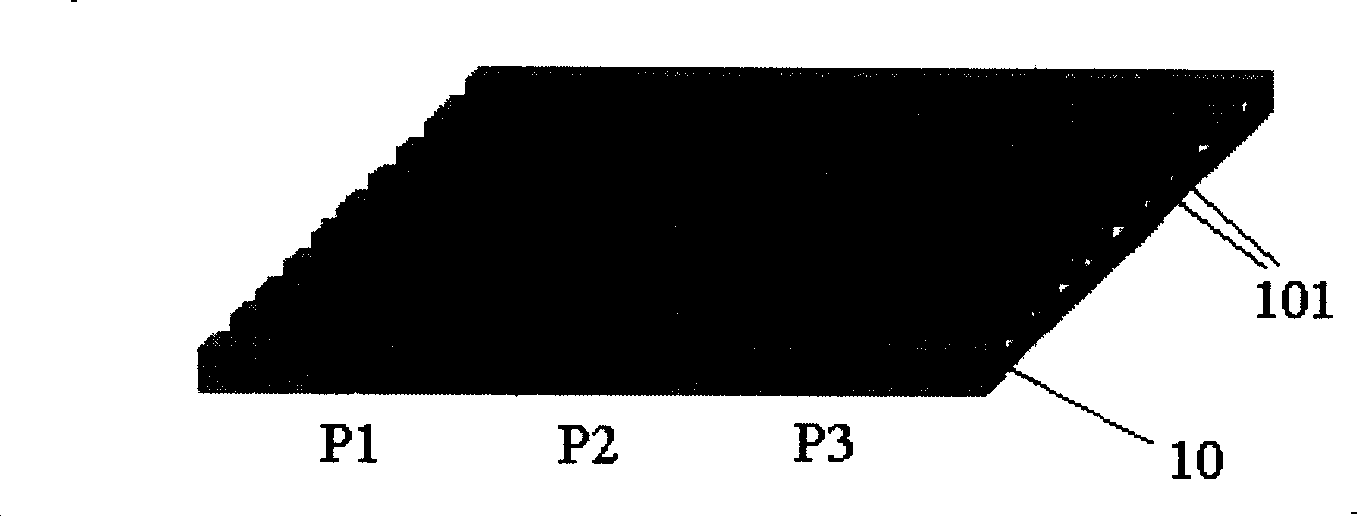

[0031] The chip bonding machine of the present invention at least includes a heating plate, a temperature control device and a vacuuming device connected to the heating plate. figure 2 It is a schematic diagram of the structure of the heating plate, which is divided into three heating areas P1, P2, and P3 along the longitudinal direction, and the temperature gradually increases, and the temperature of each heating area is controlled by the temperature control device. The surface of the heating plate is provided with several parallel slots 10, and each slot 10 corresponds to the region P3 with the highest temperature. open and close state.

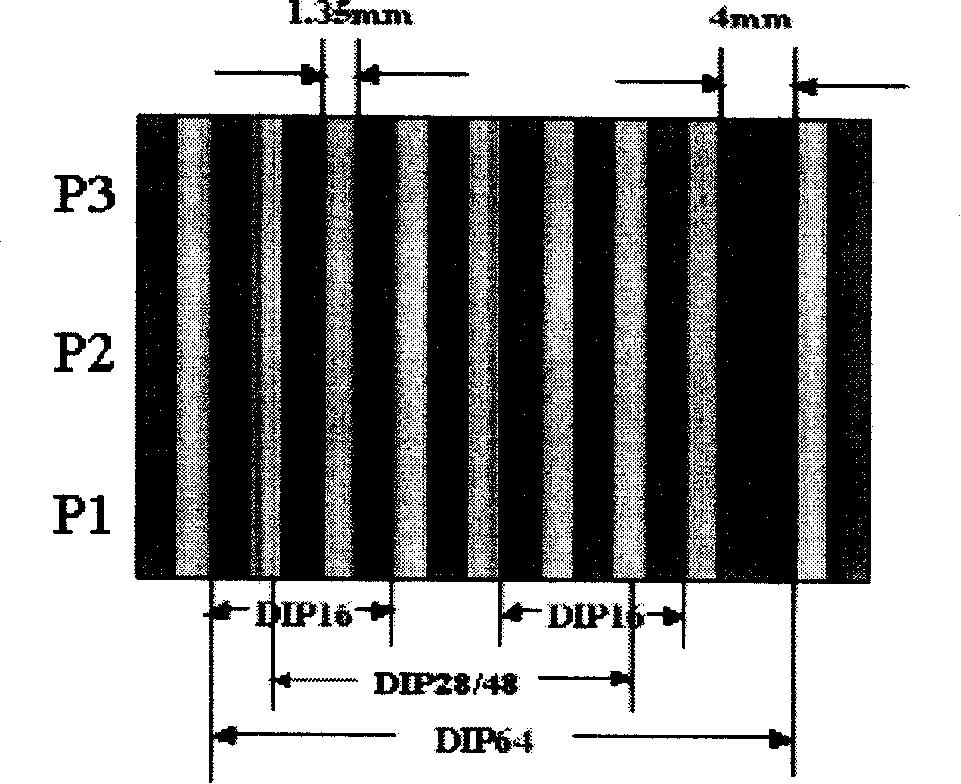

[0032] The width of the card slot 10 on the heating plate and the distance between two adjacent card slots 10 are set according to the span of two rows of parallel pins of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com