Fuel cell system

A fuel cell system and fuel cell stack technology, which is applied in the direction of fuel cell grouping, etc., can solve the problems of reducing the freedom of layout design and storage, and achieve the effect of improving the degree of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

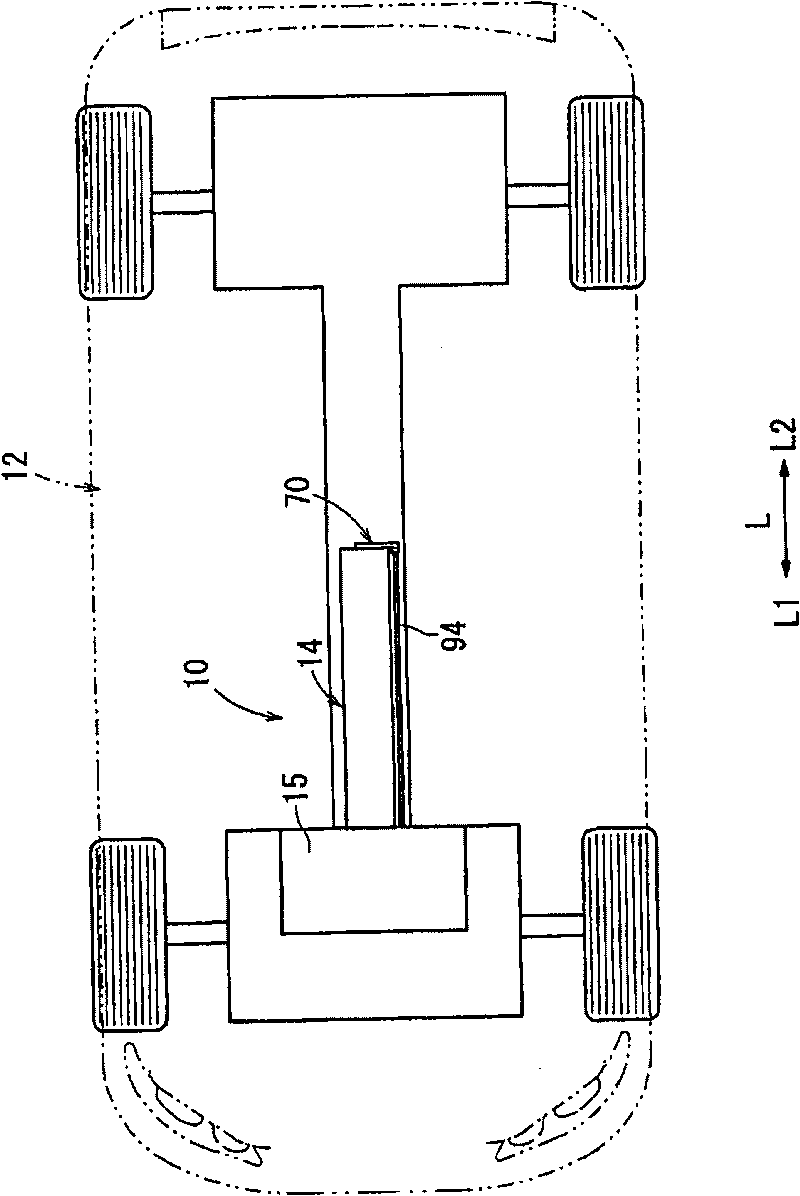

[0023] figure 1 It is an explanatory plan view of a part of a vehicle 12 equipped with the fuel cell system 10 according to the first embodiment of the present invention.

[0024] The fuel cell system 10 includes a fuel cell stack 14 that is arranged at a substantially central portion of the vehicle 12 in the vehicle length direction (arrow L direction). In front of the fuel cell stack 14 in the running direction (direction of arrow L1 ), a device 15 including a contactor and the like for ON / OFF controlling the supply of generated power to the fuel cell stack 14 is arranged.

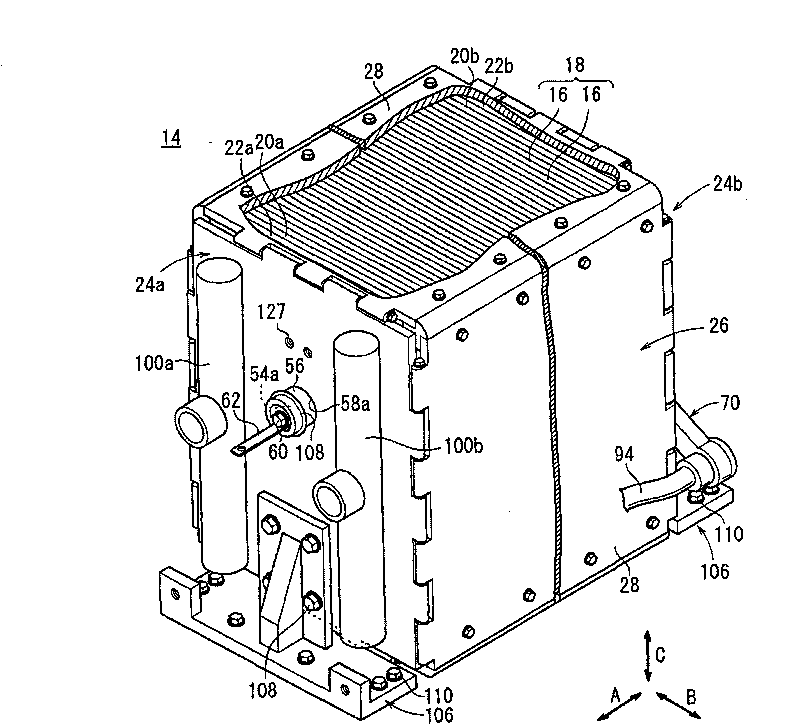

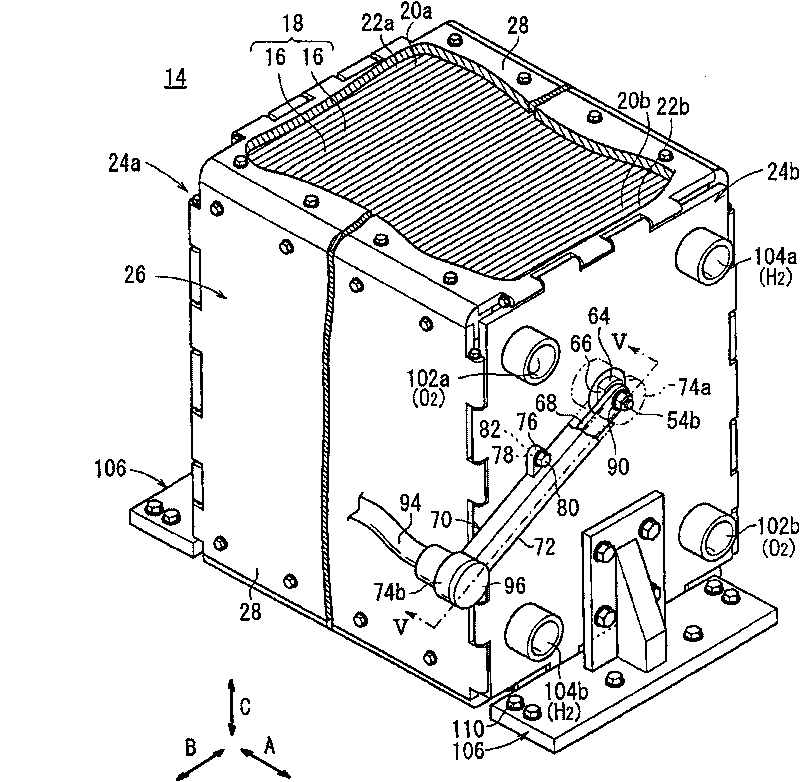

[0025] Such as figure 2 As shown, the fuel cell stack 14 is provided with a stack 18 in which a plurality of power generating elements 16 are stacked in the horizontal direction (arrow A direction). At one end in the stacking direction (arrow A direction) of the stacked body 18, the terminal plate 20a, the insulating plate 22a, and the end plate 24a are arranged facing outward. At the other end in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com