Flat plate exploder capable of improving velocity of flyer

A flying piece and flat plate technology, which is applied in the direction of blasting barrels, offensive equipment, weapon accessories, etc., can solve the problems of expensive special explosives, etc., and achieve the effects of ensuring powder sintering or synthesis quality, reducing the sparse effect, and increasing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

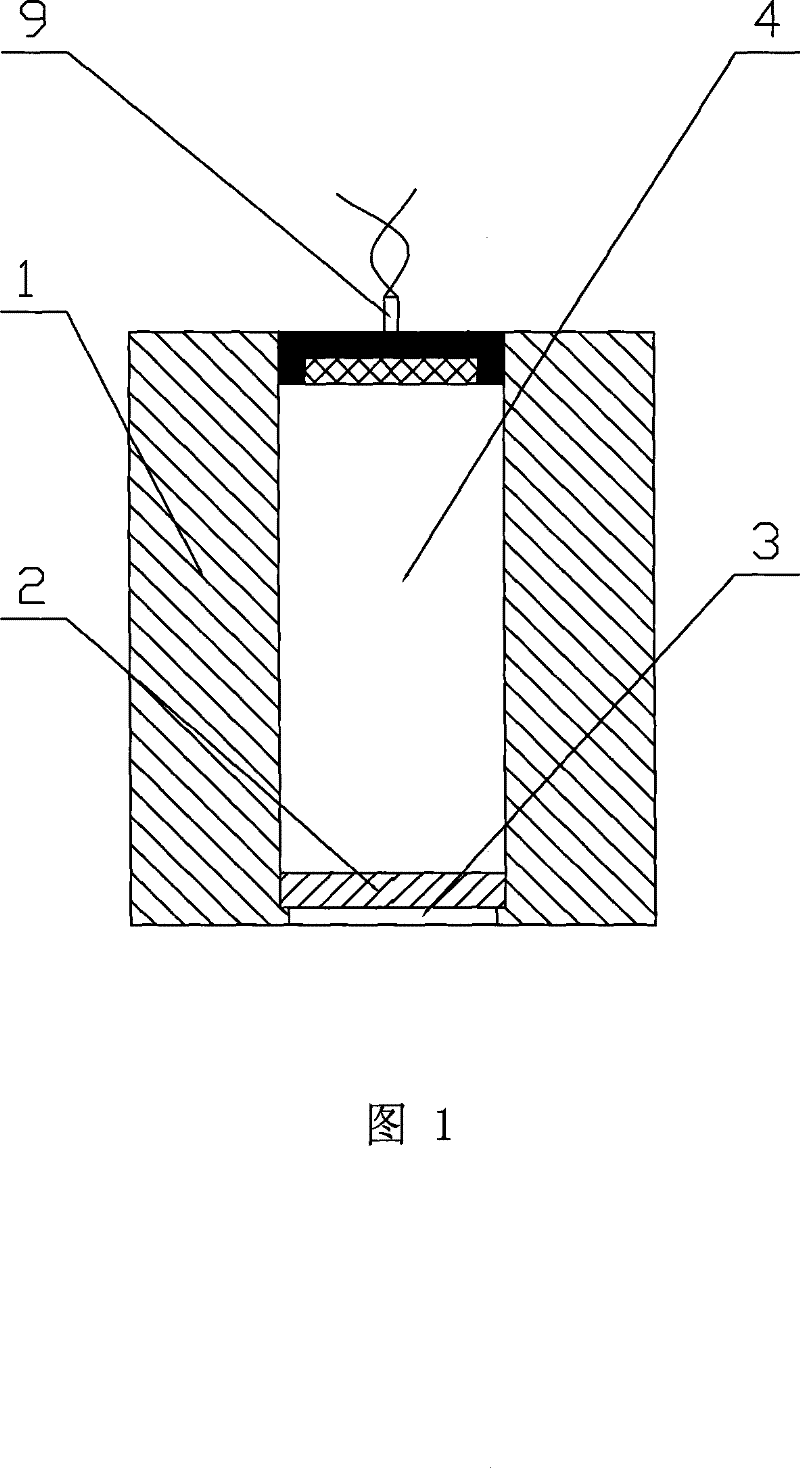

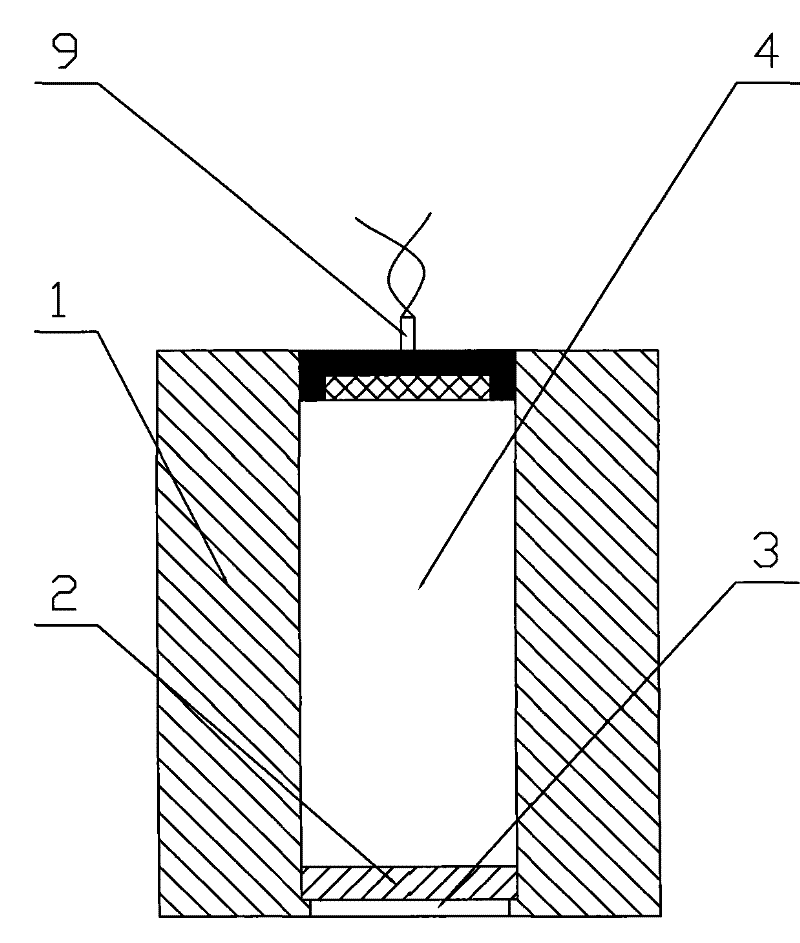

[0012] Such as figure 1 Shown: the density is 1.1 ~ 1.3g / cm 3 Hollow cylinder made of pure cement or polyurethane and other low-density plastics, that is, medium cylinder 1, medium cylinder 1 has a bottom cover, its outer diameter is 278mm, inner diameter is 118mm, and height is 120mm. It is convenient for the flying piece 2 to be placed on the central hole 3 . The inner diameter of the medium cylinder 1 is equal to the diameter of the explosive column 4. The explosive column 4 is placed on the fly piece 1 and connected to the inner wall of the medium cylinder 1. The height of the medium cylinder 1 is 10mm higher than that of the explosive column 4. The detonator on the explosive column 3 should be ensured 9 exposed above the medium cylinder 1, so that detonation. Explosive column 4 can be the smooth cylinder of outer surface, preferably such as image 3 As shown, the cylindrical surface of the explosive column 4 is provided with evenly distributed vertical ribs with a tria...

Embodiment 2

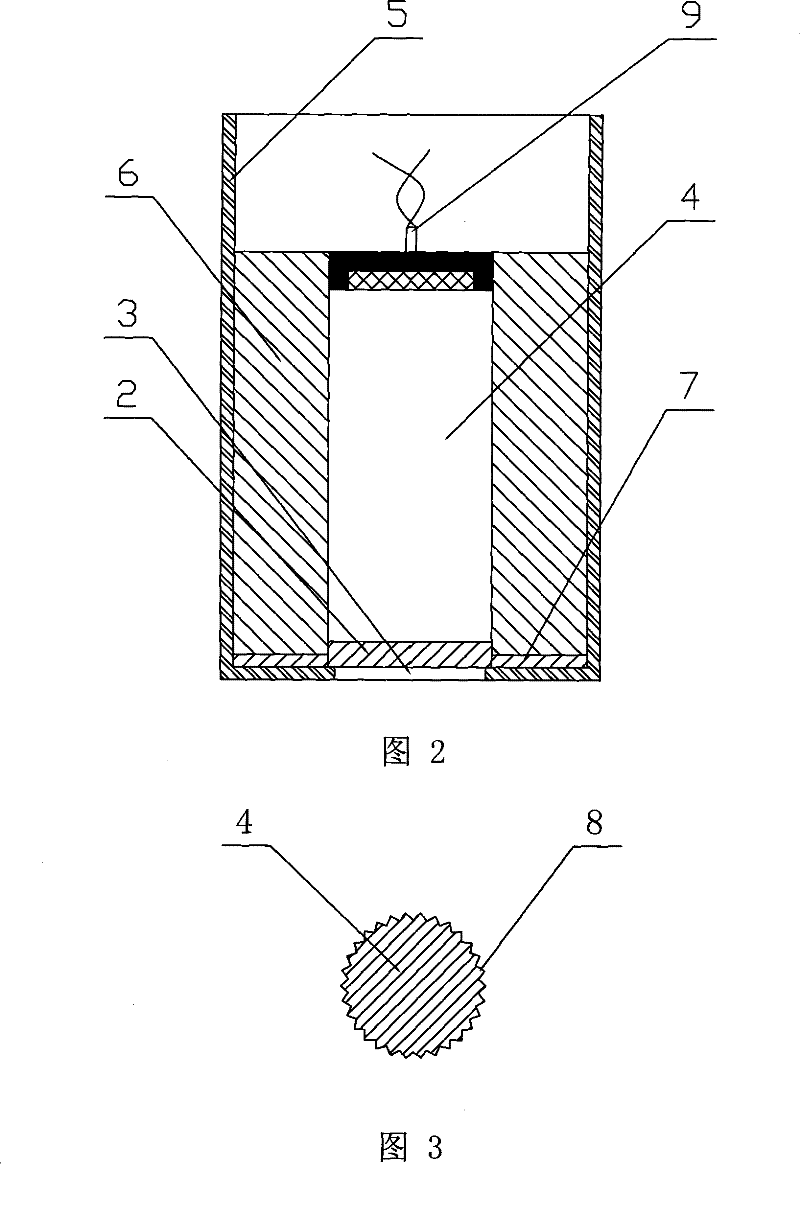

[0015] Such as figure 2 Shown: plastic drum 5 is arranged, and there is the center hole 3 that diameter is slightly smaller than flying sheet 2 at the center of the bucket bottom of plastic drum 5, and flying sheet 2 is pressed on the center hole 3, and explosive column 4 is placed on flying sheet 2, and the plastic The barrel 5 is filled with water 6, the plastic barrel 5 and the water 6 form a medium barrel 1 wrapped outside the explosive column 4, and a steel plate 7 with a thickness of 2 to 3 mm is provided inside or outside the barrel bottom of the plastic barrel 5, which can be placed on On or glued to the bottom of the barrel. The external diameter of plastic barrel 5 is 3 times of explosive column 4 diameters, and the height of water 6 is exactly the height of medium column 1, should be higher than explosive column 30mm, and detonator 9 can detonate in water 6 or in air.

[0016] The present embodiment explosive density 1.62g / cm 3 , the detonation velocity is 7500m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com