Asphalt cement mortar stirring mainframe

A mixing machine and cement mortar technology, applied in the field of construction mixing machinery, to achieve reliable transmission, reduce mixing effect, and improve cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

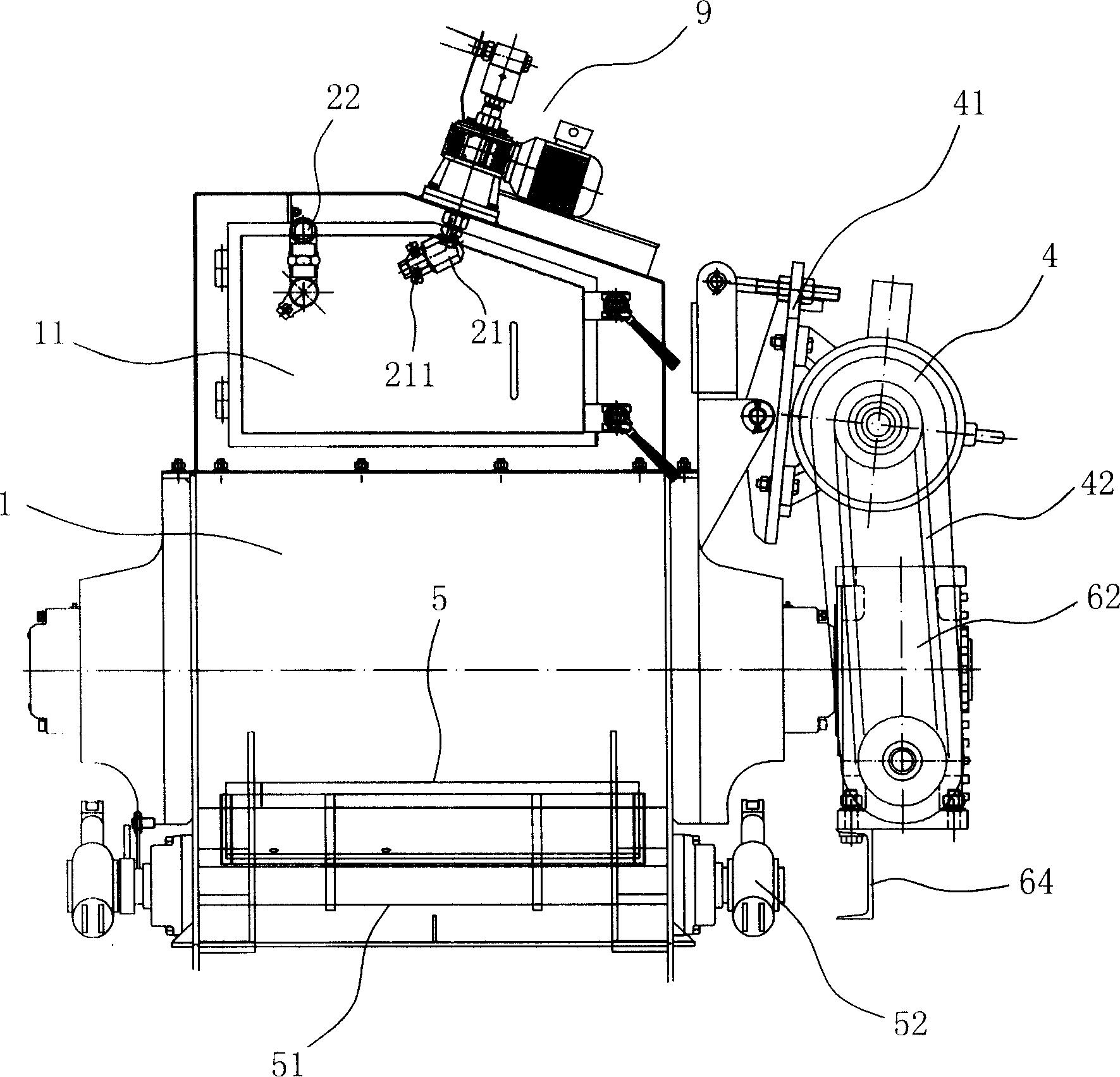

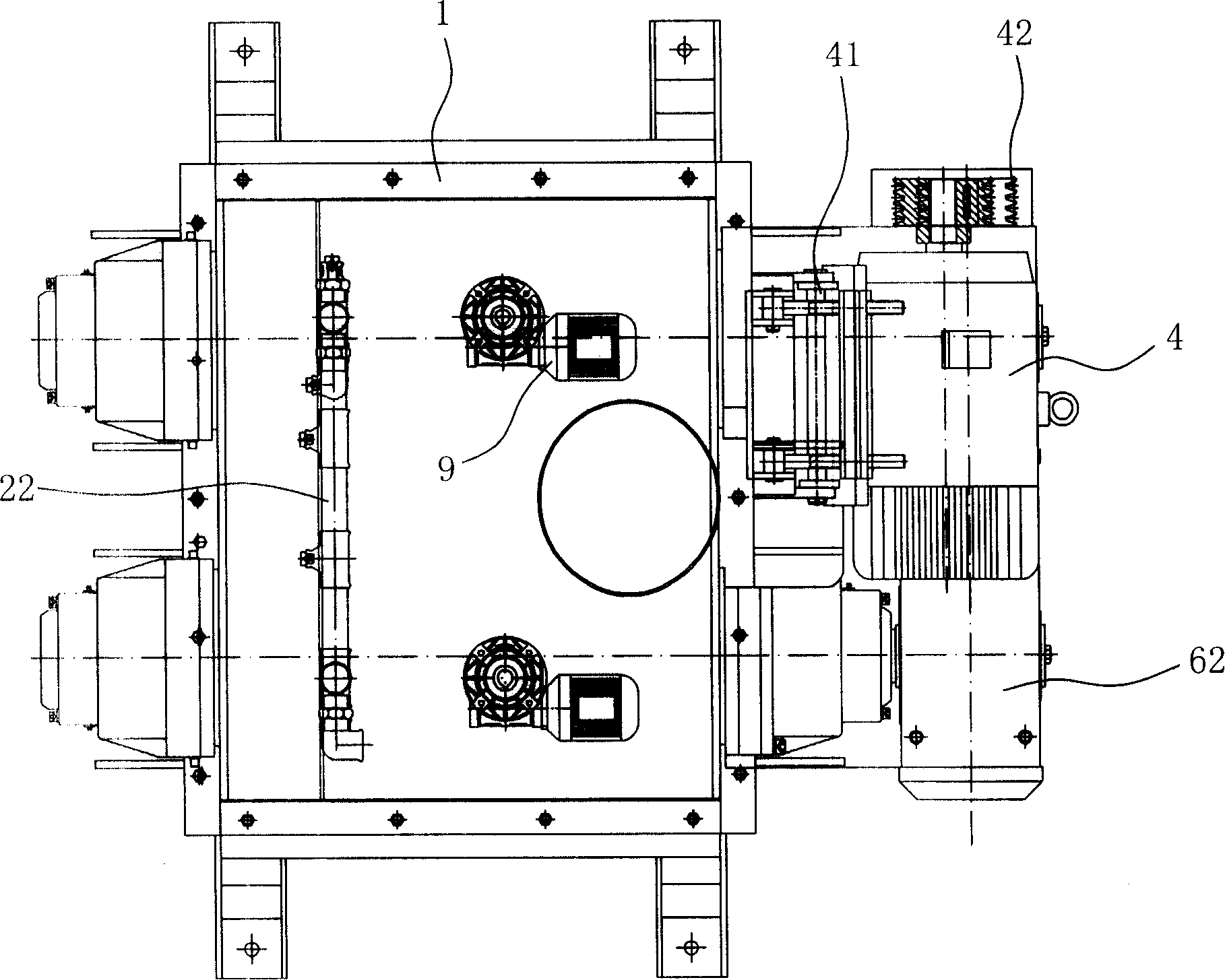

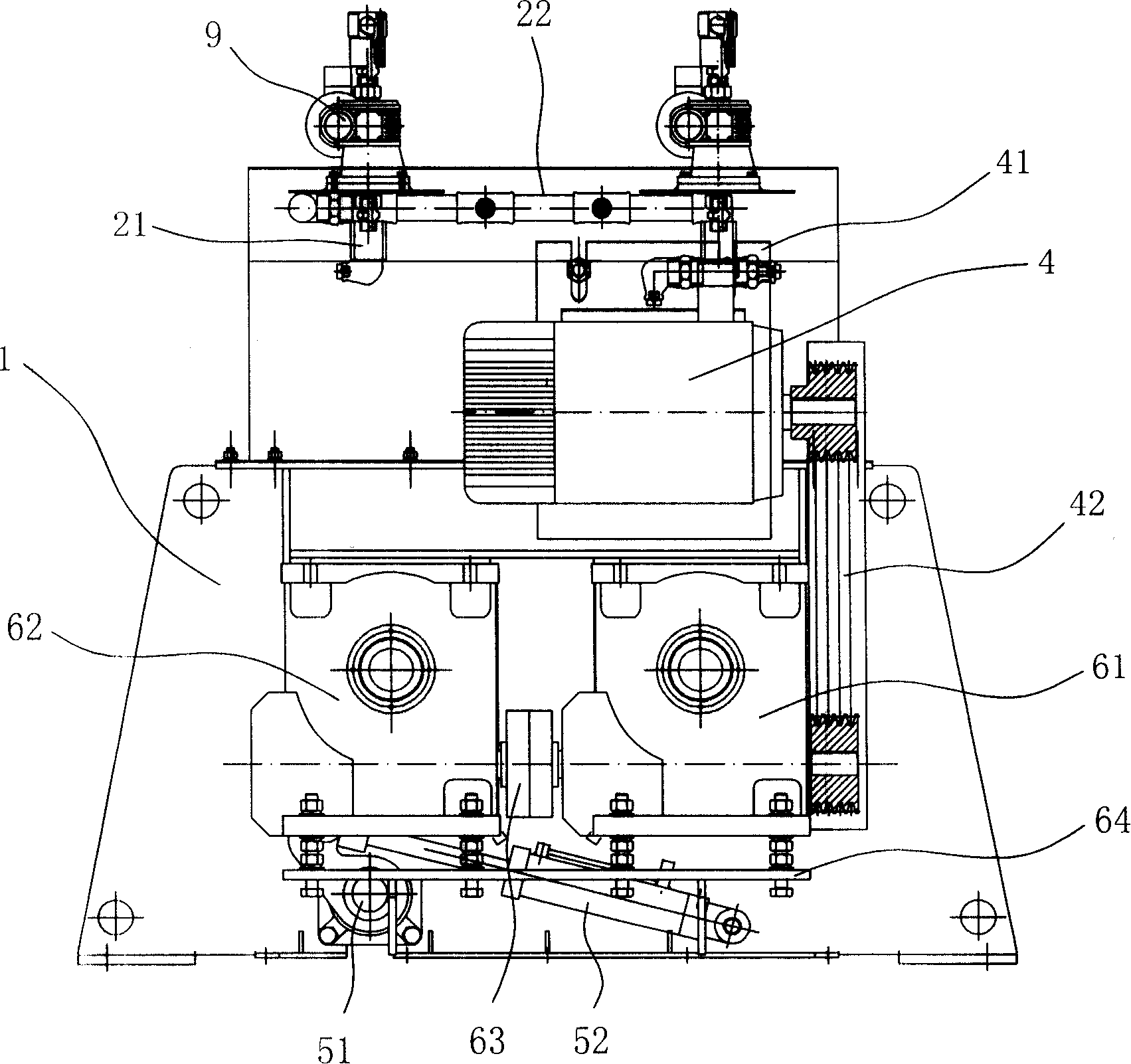

[0026] refer to Figure 1 to Figure 6 . The asphalt cement mortar mixing main engine includes a machine body 1 with an openable inspection door 11 on the upper part; a high-pressure rotary nozzle 21 and a low-pressure water supply pipeline 22 are installed on the top of the machine body 1; Stirring shafts 31, 32; adjustable speed dragging motor 4 is installed on the body 1 through an adjustable motor bracket 41; the bottom of the body 1 is provided with a large discharge door 5 that can close the opening along the bottom length of the entire stirring tank. The machine body 1 adopts a fully welded symmetrical structure, and the stirring liner can be interchanged, which is convenient for assembly and maintenance.

[0027] With reference to the figure, two agitating shafts 31, 32 corresponding to the overhanging shaft ends are respectively suspended by a reducer 61, 62 driven by a worm gear, and the two reducers 61, 62 are connected by a synchronous coupling 63; the two reducers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com