Water fin removing tool

A water fin and horizontal plane technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of increasing the pulsating pressure of the side wall of the spillway, increasing the height of the side wall of the spillway, and disorder of the flow state of the spillway, so as to eliminate the water fins. Phenomenon, simple structure, the effect of improving water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

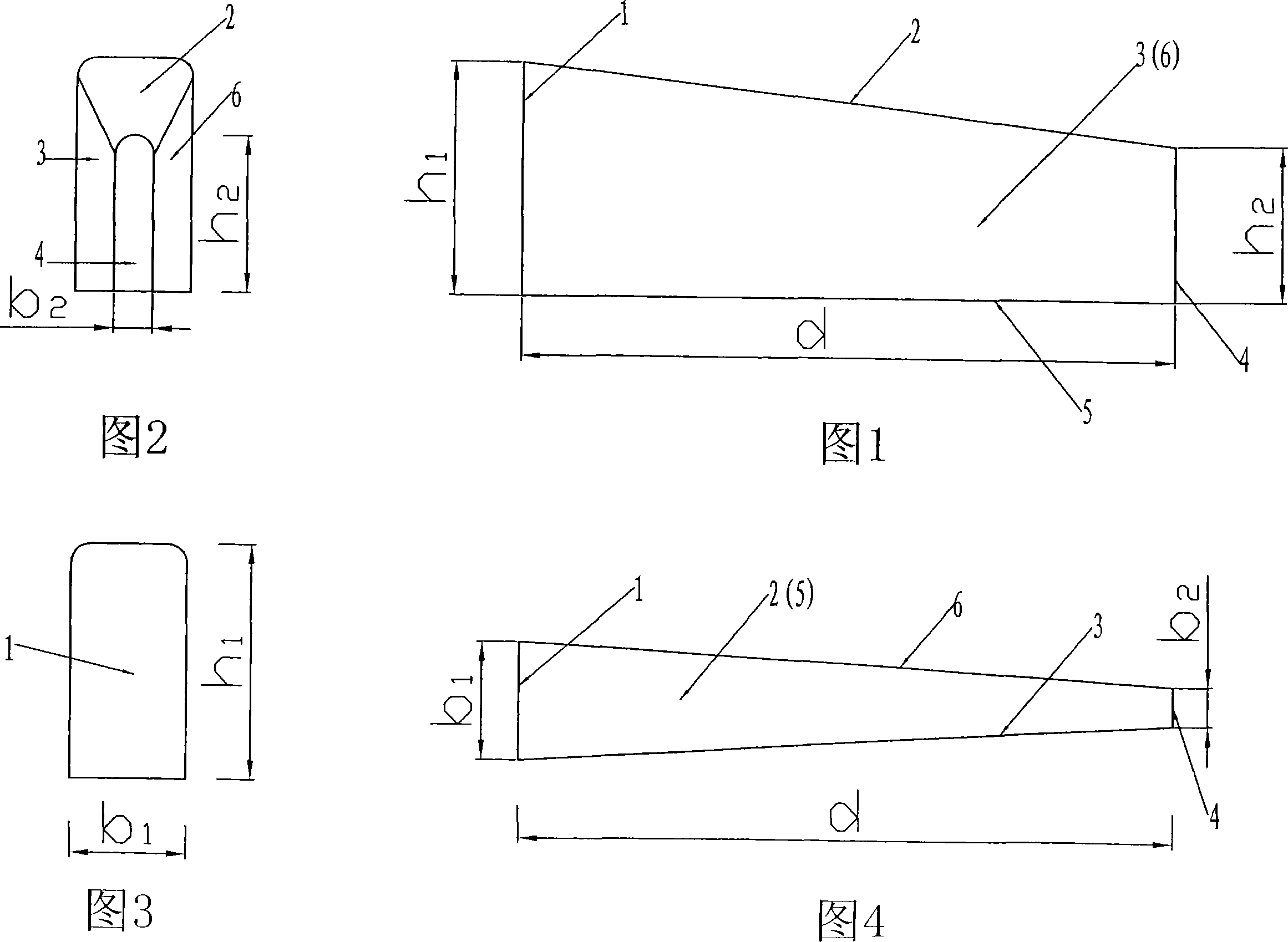

[0021] The water fin elimination tool in this embodiment is formed by pouring concrete. Its shape and structure are shown in Figure 1, Figure 2, Figure 3, and Figure 4. Located on the same horizontal plane; the front end surface 1 is a rectangular surface, the intersection of the top side of the rectangle and the two sides is connected by an arc tangent to the two intersecting sides, and the rear end surface 4 is a "∩"-shaped surface formed by a combination of a rectangle and a semicircle. The upper side 2 transitions with the right side 3 and left side 6 through arc surfaces, and the lower side 5 transitions with the right side 3 and left side 6 through edges.

[0022] According to the local topography and geological conditions, the overflow weir of the project spillway adopts a practical weir. Therefore, the relevant dimensions of the water fin elimination work are: the height h of the front face 1 1 = 7m (1.05 times the water depth at the tail of the spillway sluice pier),...

Embodiment 2

[0026] The water fin elimination tool in the present embodiment is shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, and its shape, structure are identical with the water fin elimination tool described in embodiment 1.

[0027] Because the hydrofin elimination tool described in this embodiment is used for wide-crested weirs, according to this specific project, the relevant dimensions are: the height h of the front end face 1 1 = 6m (1.03 times the water depth at the tail of the spillway sluice pier), the width b of the front end face 1 1 = 3m (the width of the spillway gate pier); the height h of the rear end face 4 2 = 4.12m (1.05 times the water depth at the installation position of the end face), the width b of the rear end face 4 2 =0.4m (0.13 times the width of the spillway pier); the distance d between the front end face 1 and the rear end face 4=17m (5.7 times the width of the spillway pier).

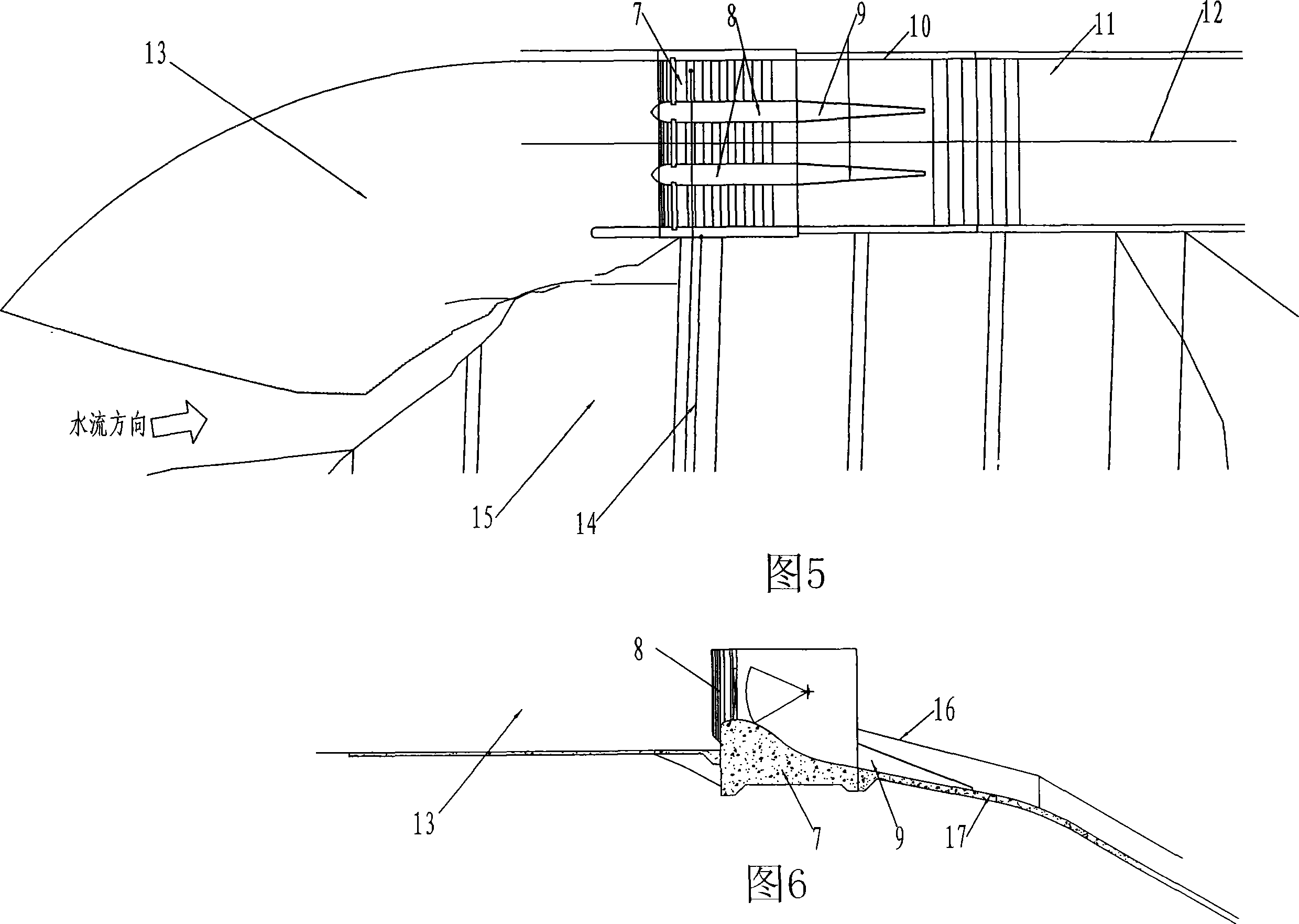

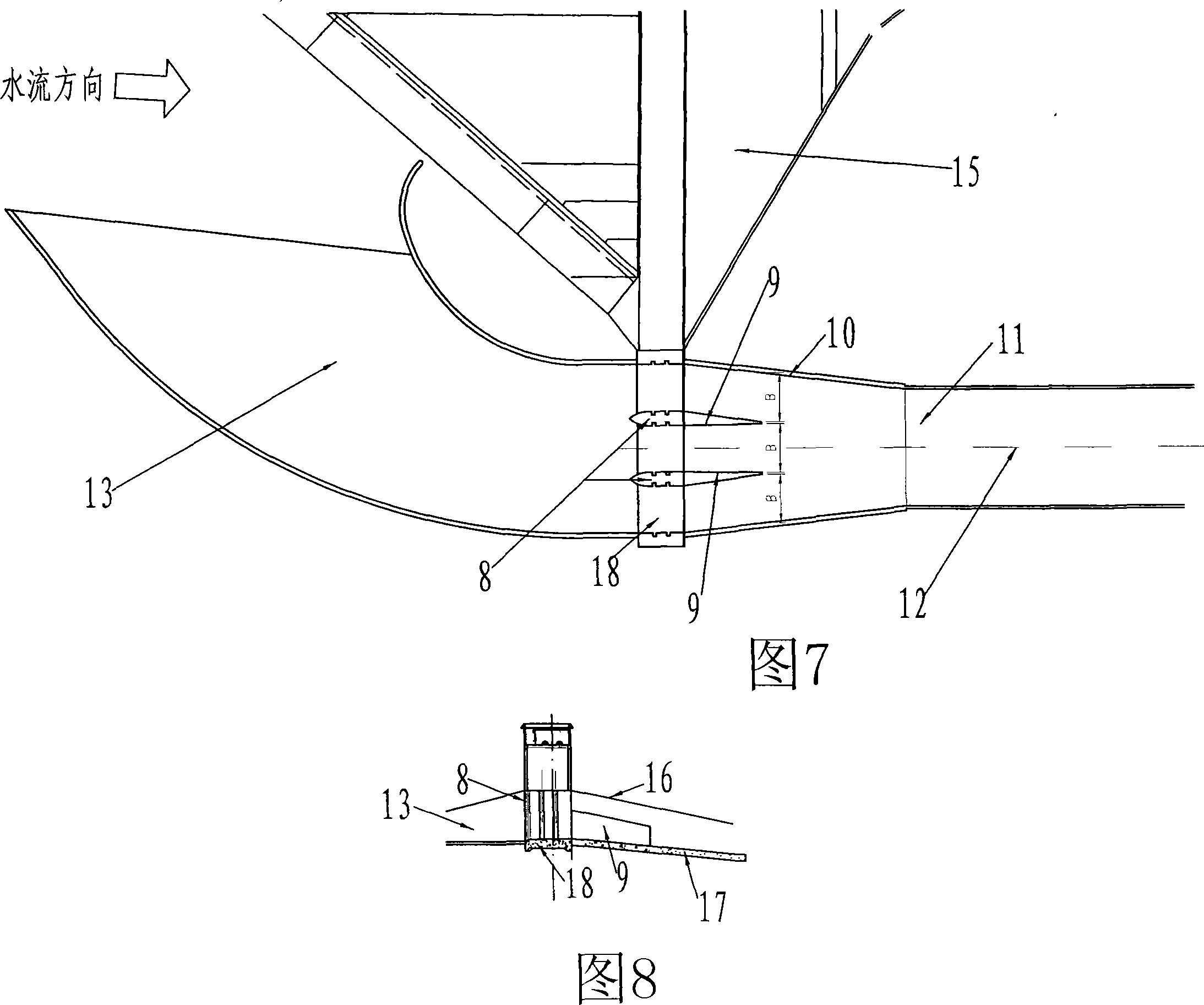

[0028] In this embodiment, two hydrofin elimination works are installed behind the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com