Steam cylinder head device possessing torsion bar

A cylinder head and torsion bar technology, applied in valve devices, engine components, machines/engines, etc., can solve problems such as valve clearance enlargement, impact on cylinder output effect, and insufficient structural rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

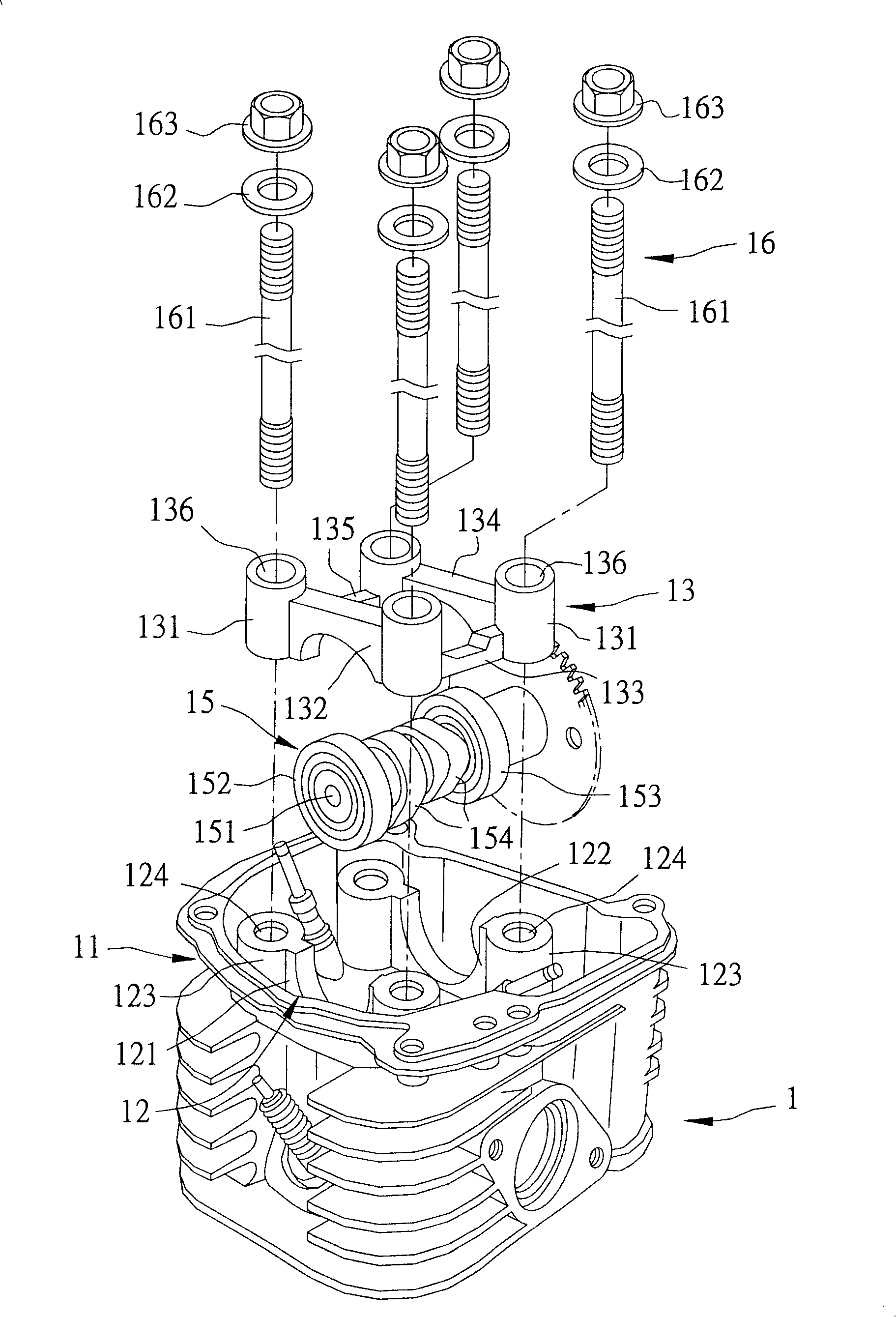

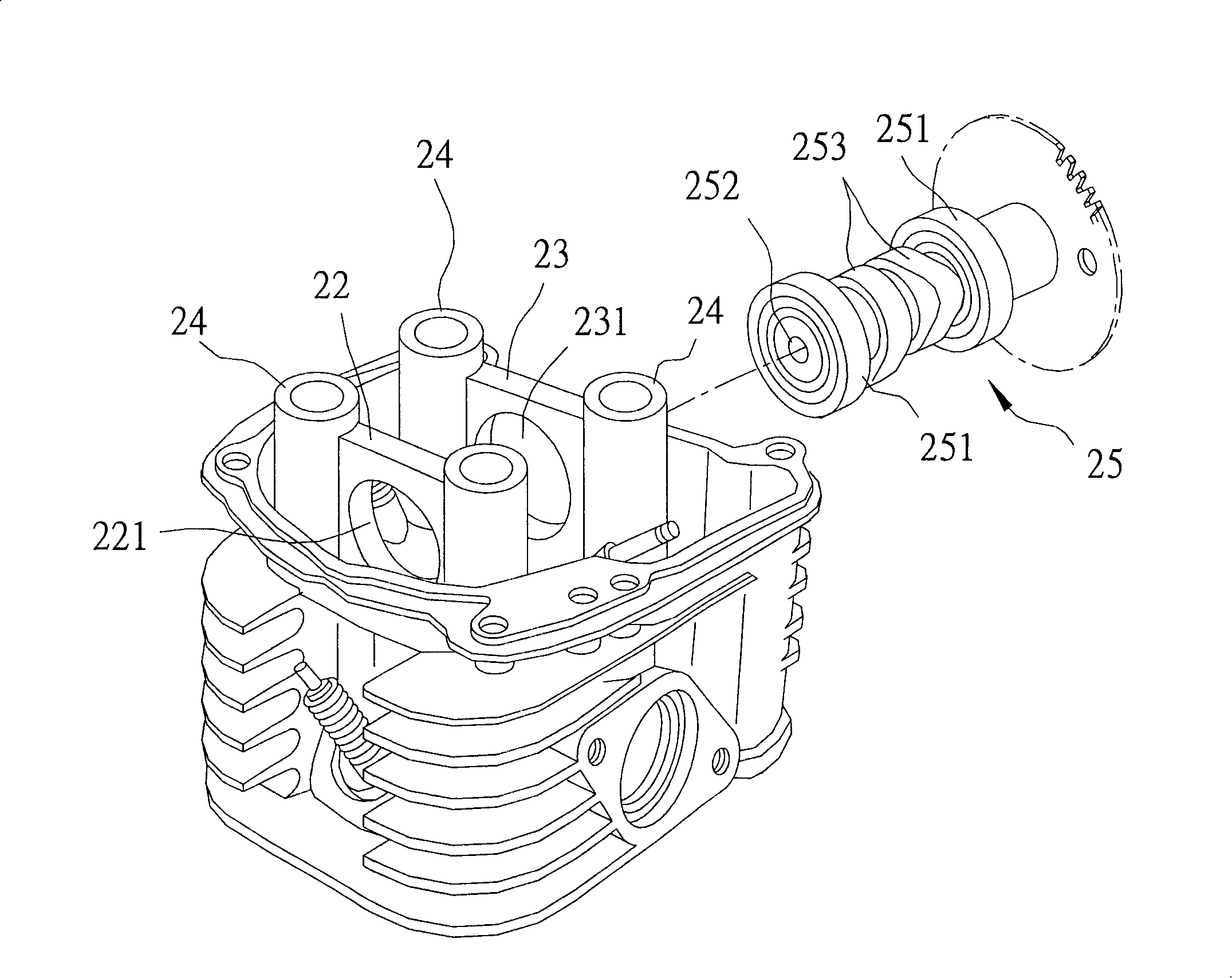

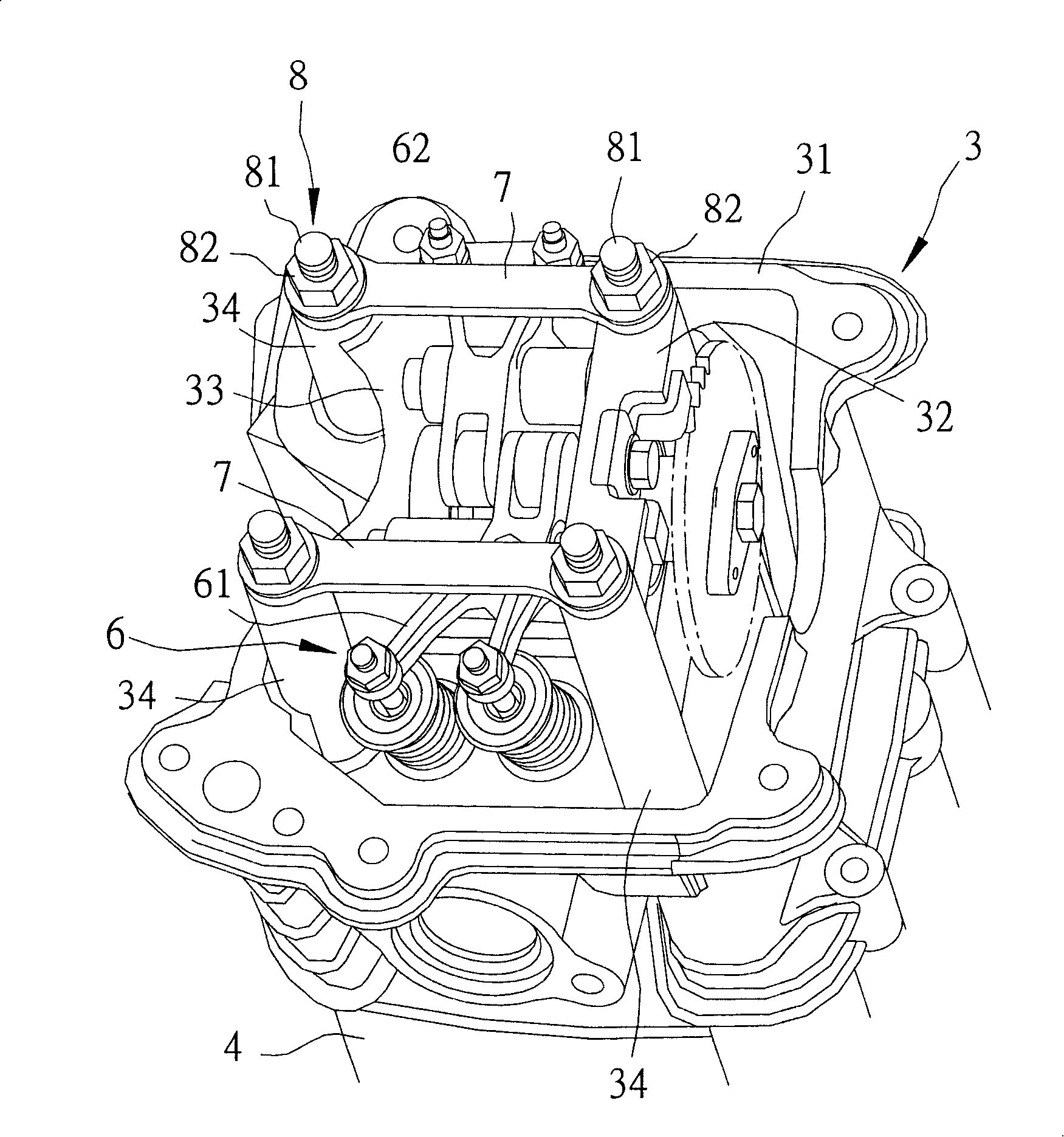

[0021] Such as image 3 , 4 Shown, the present invention has the preferred embodiment of the cylinder head device of torsion bar, is installed on a cylinder block 4, and this cylinder head device comprises a cylinder head 3, a camshaft group 5, a rocker arm unit 6, Two torsion bars 7, and a locking unit 8.

[0022] The cylinder head 3 is arranged on the cylinder block 4, and has a cylinder head body 31, a first support wall 32 and a second support wall 33 extending upwardly from the cylinder head body 31 at intervals, and the four are respectively connected. The columns 34 at both ends of the first and second support walls 32 , 33 have corresponding installation holes 321 , 331 formed on the first and second support walls 32 , 33 , and each column 34 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com