Enzymic electrode method quantitative ethanol test strip

A method of quantitative ethanol and enzyme electrode technology, applied in the field of biosensing, can solve the problems of high production cost of ethanol tester, resistance of subjects, and hygiene problems, etc., achieve intuitive and convenient results, reduce process requirements, and improve accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

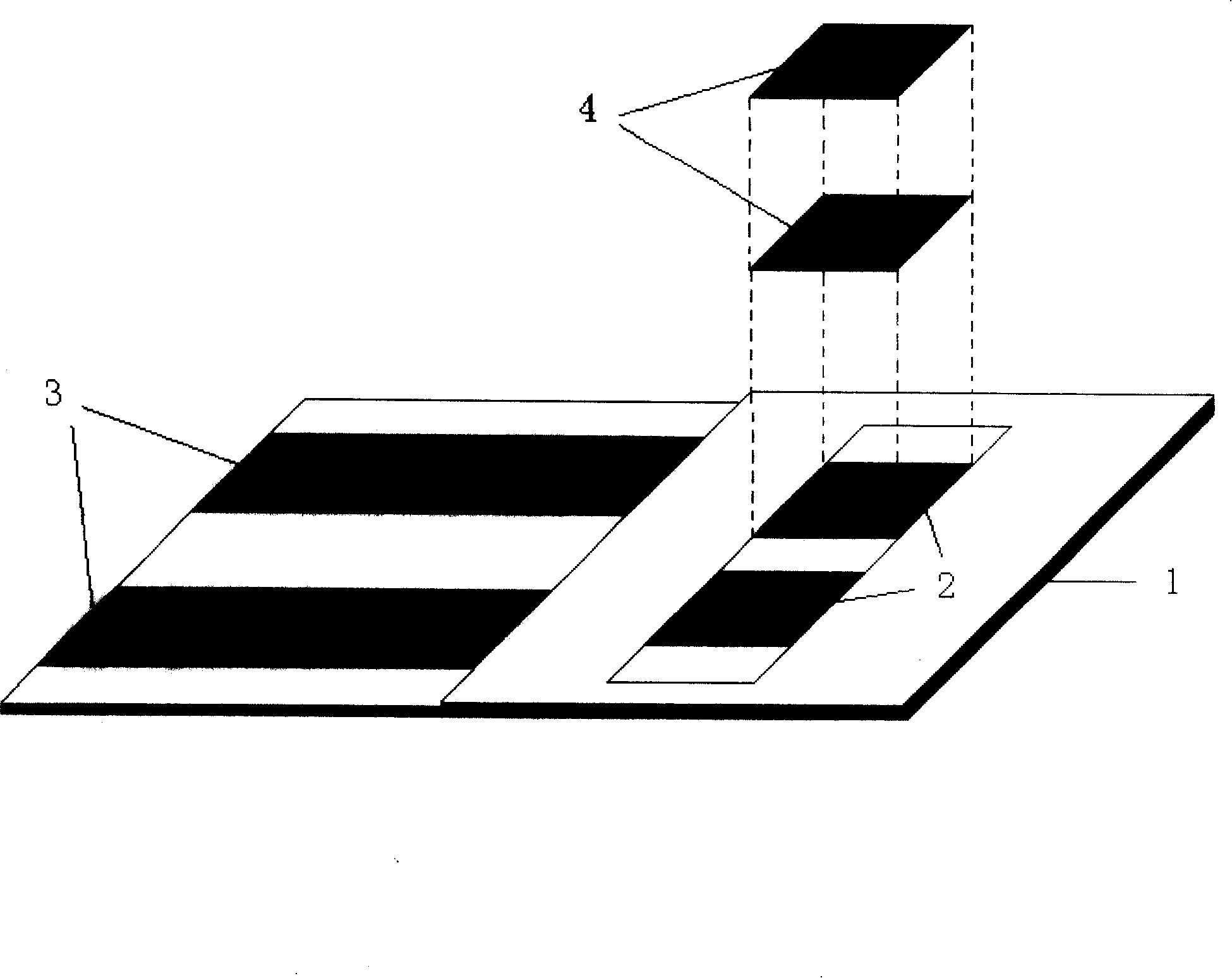

Image

Examples

Embodiment

[0013] Example: polyester sheet material, pre-cut into 80×300 mm substrates for later use.

[0014] (1) Add 15% hydroxymethyl cellulose, 20% electronic conductive carrier material potassium ferricyanide and diluent in the conductive carbon ink, mix for subsequent use;

[0015] (2) Install the electrode template on the stationary machine for standby;

[0016] (3) Alcohol oxidase with an activity of 3000 international units per milliliter is added to 120 millimoles per liter of phosphate buffered water, and at the same time, 600 milligrams of potassium ferricyanide per liter and 15% hydroxymethyl cellulose are added to fully dissolve Put it aside in the refrigerator at 4°C for later use.

[0017] Add conductive paste to the above-mentioned fixing machine to fix the conductive circuit; after drying, add the above-mentioned mixed conductive carbon ink to the automatic fixing machine to cover the previously printed silver ink circuit to make an electrode. The printed electrodes n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com