Silk screen printing method for producing blood sugar test paper

A technology of screen printing and blood glucose test strips, which is applied in the field of biosensing, can solve the problems of complex manufacturing process and unfavorable industrial scale production of products, and achieve the advantages of convenient post-processing and packaging, simplified production equipment, and guaranteed accuracy and repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

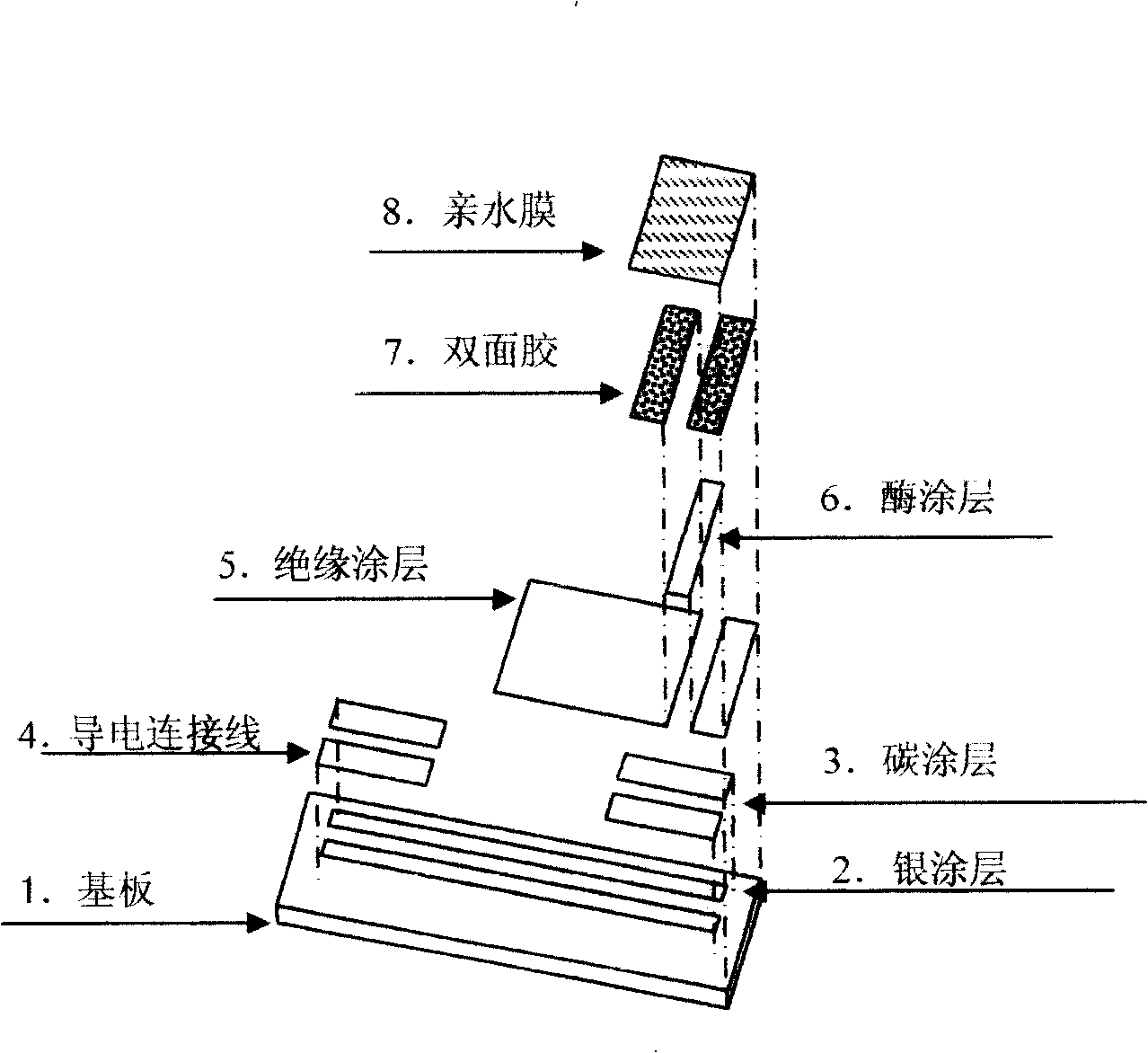

Image

Examples

Embodiment 1

[0019] Embodiment 1: Polyethylene (PVC) boards are pre-cut into 21×9 cm substrates for later use.

[0020] (1) Add 1.2% hydroxyethyl cellulose and 10% benzoquinone, an electronically conductive carrier material, to 1 gram of silk-screen conductive carbon ink (Acheson 423SS), mix well and set aside.

[0021] (2) Fix the 280-mesh metal or nylon polyester material screen on the square light metal frame, apply Kodak photosensitive glue in the dark room, and dry it for later use.

[0022] (3) Place the computer-drawn negatives of the working electrode and the reference electrode on the photosensitive adhesive, and expose them to a 20-watt ultraviolet lamp for 15 minutes. Rinse off the unhardened photosensitive adhesive covered by the electrode negative with a high-pressure water gun. After drying, a screen printing template is formed.

[0023] (4) Install the screen printing template with the working electrode and reference electrode graphics on the (DEK-245) automatic screen pri...

Embodiment 2

[0028] Embodiment 2: polyester (PET) sheet material, cut into 21 * 9 centimeter substrates in advance for future use.

[0029] (1) Add 1.8% hydroxyethyl cellulose and 15% benzoquinone, an electronically conductive carrier material, to the silk-screen conductive carbon ink (Acheson423 SS). After mixing, set aside in the refrigerator at 4°C for later use.

[0030] (2) Fix the 300-mesh metal or nylon polyester wire mesh on a square light metal frame, apply Kodak photosensitive glue in the dark room, and dry it for later use.

[0031] (3) Place the computer-drawn negatives of the working electrode and the reference electrode on the photosensitive adhesive, and expose them to light for 25 minutes under a 20-watt ultraviolet lamp. Rinse off the unhardened photosensitive adhesive covered by the electrode negative with a high-pressure water gun. After drying, a screen printing template is formed.

[0032] (4) Install the screen printing template with the working electrode and refer...

Embodiment 3

[0035] Embodiment 3: Polyphenol ester (PP) boards, which are pre-cut into 21×9 cm substrates for later use.

[0036] (1) Add 2.5% hydroxyethyl cellulose to the conductive carbon ink for silk screen printing, add 20% potassium ferricyanide, an electronically conductive carrier material, and mix for subsequent use;

[0037] (2) Fix the 350-mesh metal or nylon polyester material screen on the square light metal frame, apply Kodak photosensitive glue in the dark room, and dry it for later use;

[0038] (3) Place the working electrode and the reference electrode negative film drawn by the computer on the photosensitive glue, expose to light for 30 minutes under a 40-watt ultraviolet lamp, rinse off the unhardened photosensitive glue covered by the electrode negative film with a high-pressure water gun, and form a silk screen template after drying;

[0039] (4) Install the screen printing template with working electrode and reference electrode graphics on the automatic screen printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com