A fluorescent tube for slim pipe diameter

A technology for fluorescent tubes and tubes, applied in the field of fluorescent tubes, which can solve the problems of reducing the amount of electronic powder coating, affecting the pumping speed, and reducing the distance, so as to avoid the phenomenon of filament bumping into walls, improve the production pass rate, and ensure coating volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

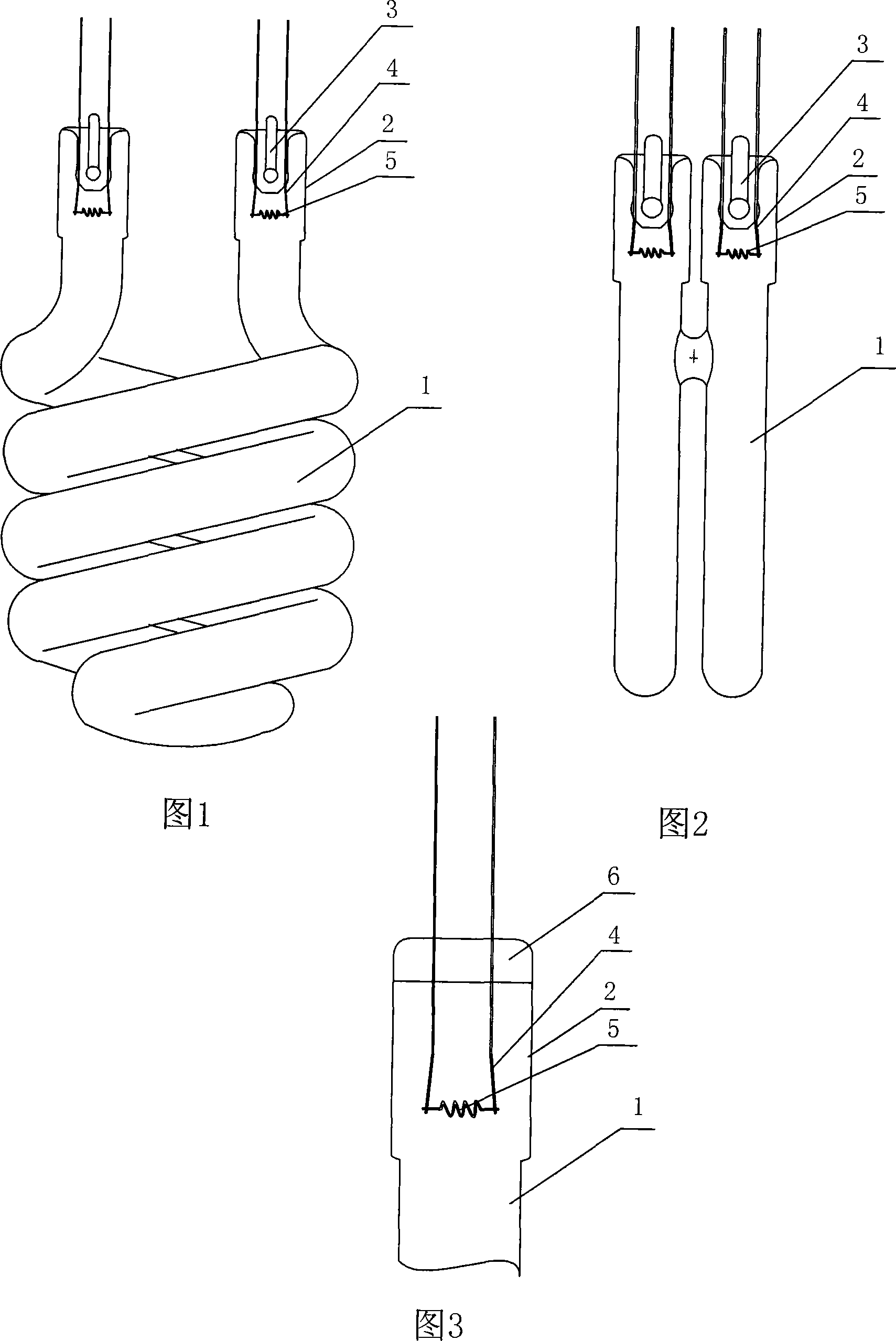

[0015] Embodiment 1: As shown in Figure 1, a fluorescent tube with a small diameter includes a main tube 1, the end of the main tube 1 is fused with an auxiliary tube 2, the main tube 1 is a spiral glass tube, The diameter of the main lamp tube 1 is Φ4mm, the diameter of the auxiliary lamp tube 2 is Φ7mm, the end of the auxiliary lamp tube 2 is sealed and fixed with a stem 3, the stem 3 is provided with a guide wire 4 and a filament 5, and the filament 5 is set In the auxiliary lamp tube 2.

Embodiment 2

[0016] Embodiment two: as shown in Figure 2, other structures are the same as embodiment one, the difference is that the main body lamp tube 1 is a U-shaped glass tube, the tube diameter of the main body tube 1 is Φ5mm, and the tube diameter of the auxiliary lamp tube 2 is Φ9mm.

Embodiment 3

[0017] Embodiment 3: As shown in Figure 3, other structures are the same as Embodiment 1 or Embodiment 2, the difference is that the diameter of the main lamp tube 1 is Φ6mm, the diameter of the auxiliary lamp tube 2 is Φ8mm, and no stem is used Instead, the end of the auxiliary lamp tube 2 is fused and pinched to form a pinch portion 6 , and the guide wire 4 connected to the filament 5 is fixed on the pinch portion 6 .

[0018] In the above embodiments, the main lamp tube 1 can also be replaced by other glass tubes of various shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com