Making method for miniature sound part

A manufacturing method and technology of sound-generating devices, applied to sensors, electrical components, etc., can solve problems such as polluting the diaphragm, unstable product performance, and glue flowing to other parts, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

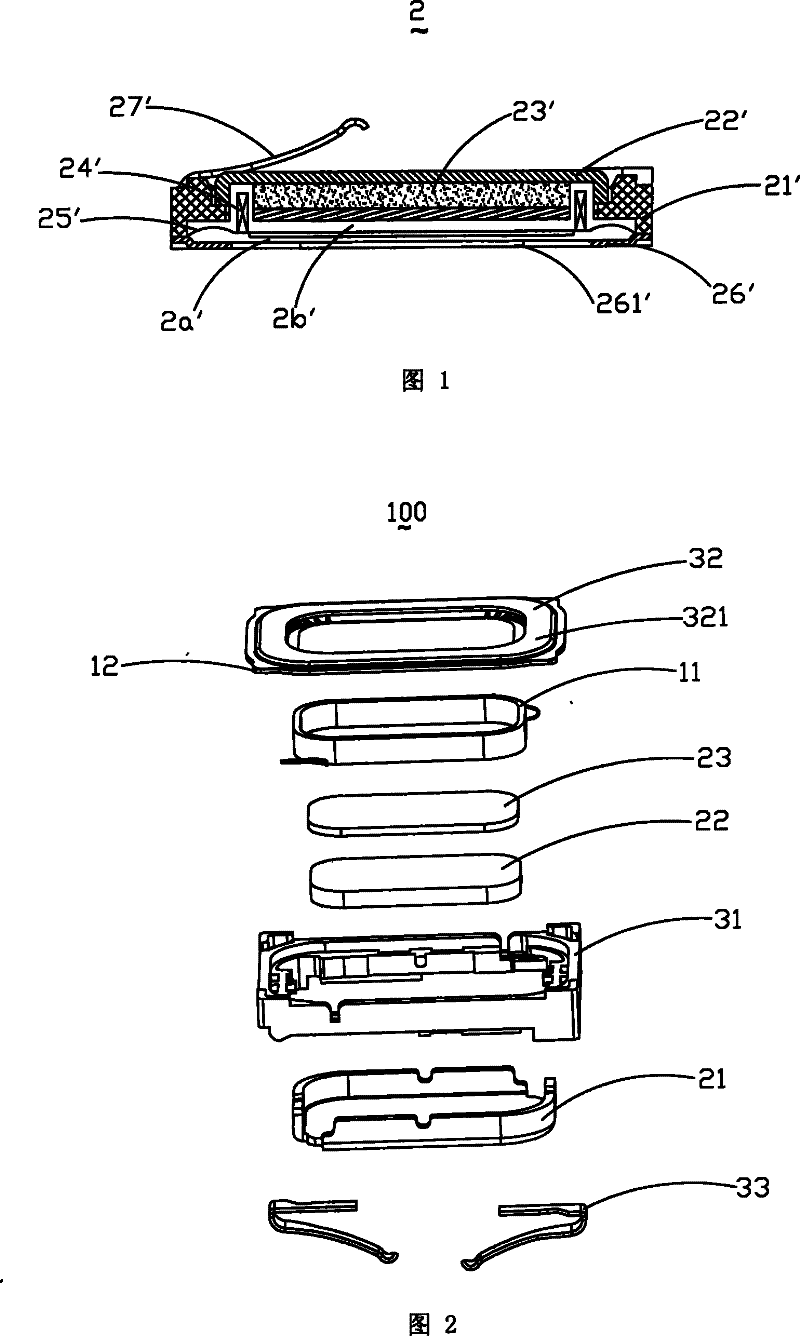

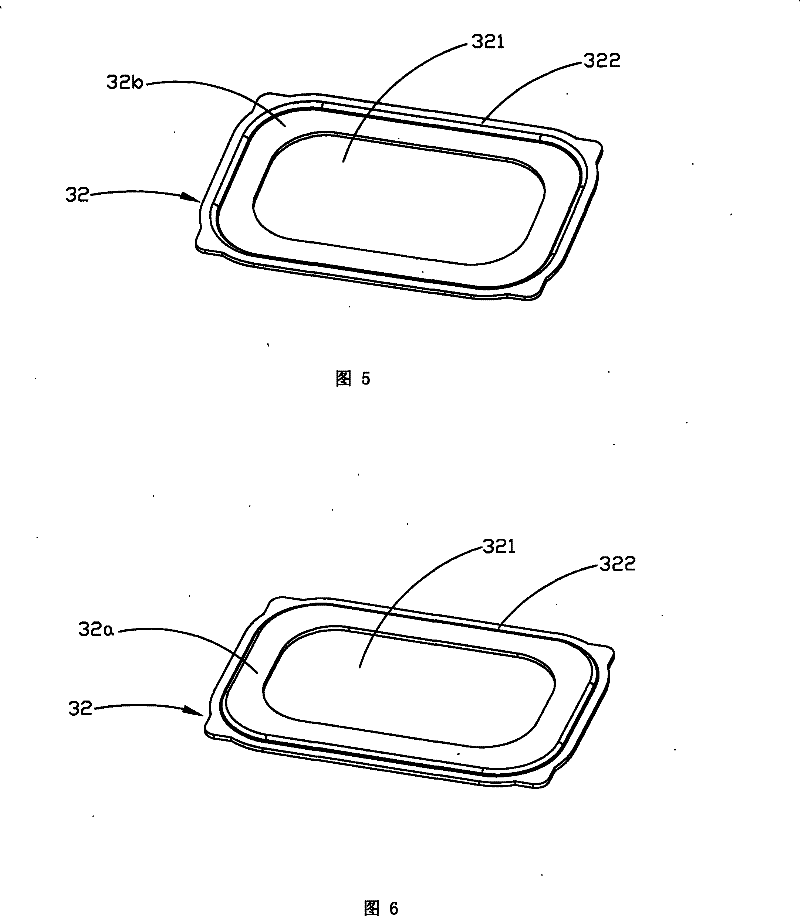

[0020] Such as figure 2 As shown, the micro-sounding device 100 of the present invention includes a vibration system, a magnetic circuit system and an auxiliary system, wherein the vibration system includes a diaphragm 12 and a voice coil 11, and the magnetic circuit system includes a magnetic bowl 21 and a permanent magnet accommodated in the magnetic bowl 21 22 and pole piece 23, the magnetic bowl 21 and the permanent magnet 22 and the pole piece 23 form a magnetic gap (not shown) to accommodate the voice coil 11, and the auxiliary system includes a basin frame 31 for accommodating the magnetic bowl 21, a cover connected with the basin frame 21 The upper cover 32 and the conductive strips 33 installed at opposite corners of the basin frame 31 .

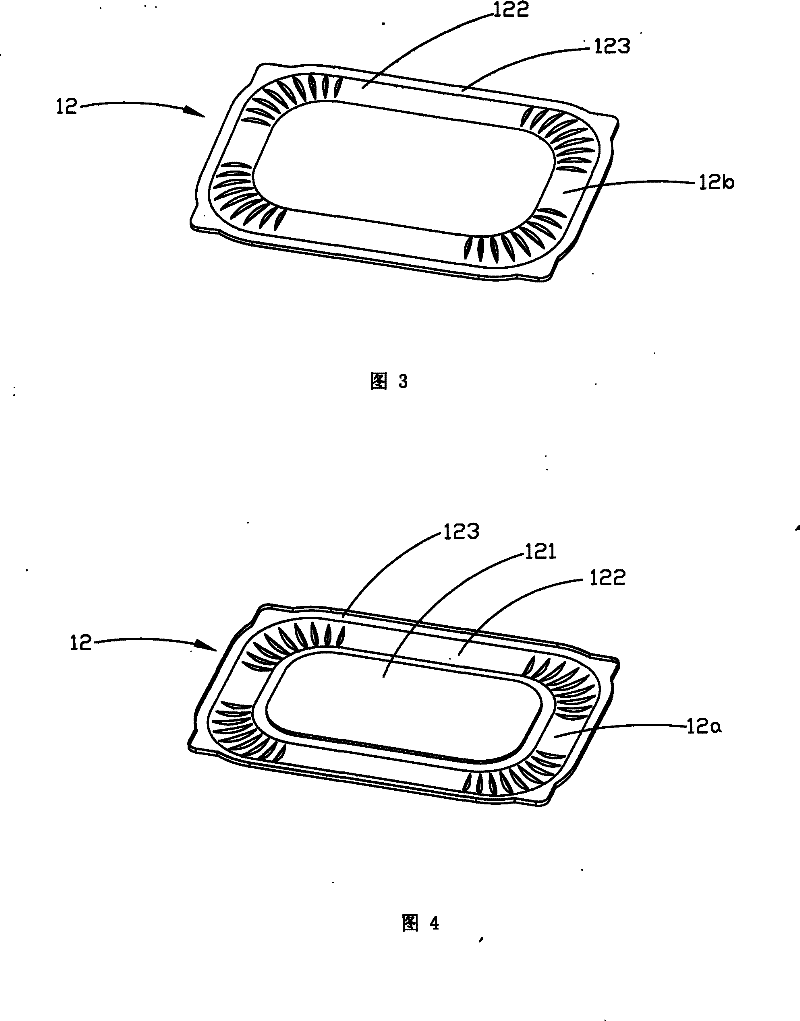

[0021] Among them, such as image 3 and 4 As shown, the diaphragm 12 includes a front surface 12a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com