Chemical mechanical polishing method for GaAs wafer

A mechanochemical polishing and wafer technology, applied in the field of polishing, can solve problems such as inability to ensure flatness and smoothness, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

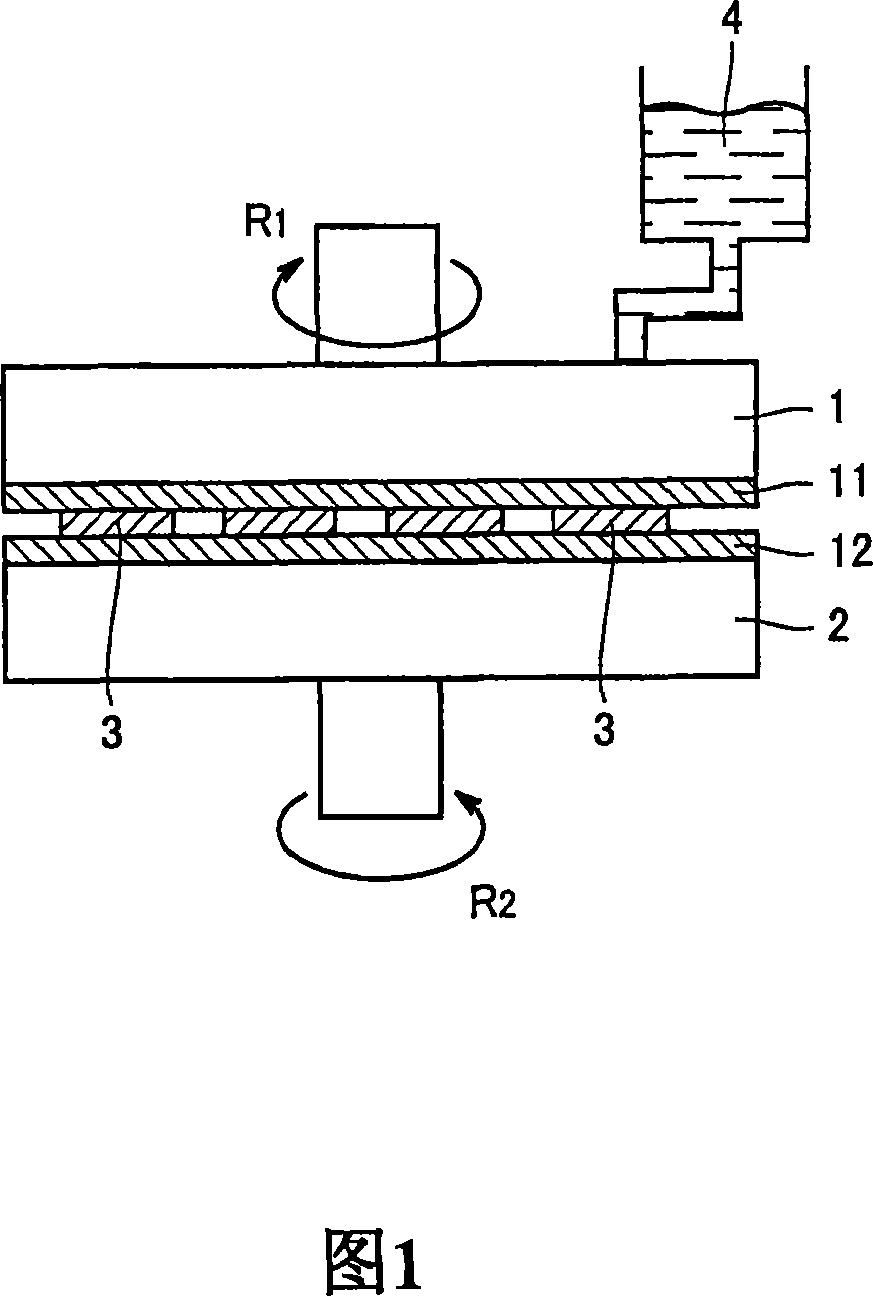

Image

Examples

Embodiment Construction

[0018] As previously described, it is known that a polishing solution containing dichloroisocyanuric acid, sodium tripolyphosphate, sodium sulfate, sodium carbonate, and silica gel as components in addition to water can be used for mechanochemical polishing of a GaAs wafer as a preliminary polishing, (e.g. , see Japanese Patent Laid-Open No. 2005-264057 and Japanese Patent Laid-Open No. 11-283943).

[0019] Regarding this mechanochemical polishing solution, it is natural that the polishing rate of GaAs wafers and the flatness and smoothness of polished wafers are significantly affected depending on the ratio of components other than water.

[0020] Therefore, in the mechanochemical polishing using as primary polishing a polishing solution containing dichloroisocyanuric acid, sodium tripolyphosphate, sodium sulfate, sodium carbonate, and silica gel as components in addition to water, the present inventors varied the water removal Ratio of other components in an attempt to incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com