Self-discharging method of self-discharging bulk carrier and balk cargo

A technology for bulk cargo ships and bulk materials, applied in the direction of bulk cargo, ship accessories, transportation and packaging, etc., can solve the problems of increased expenses, long unloading time, time-consuming, etc., to reduce shipping costs, fast unloading speed, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

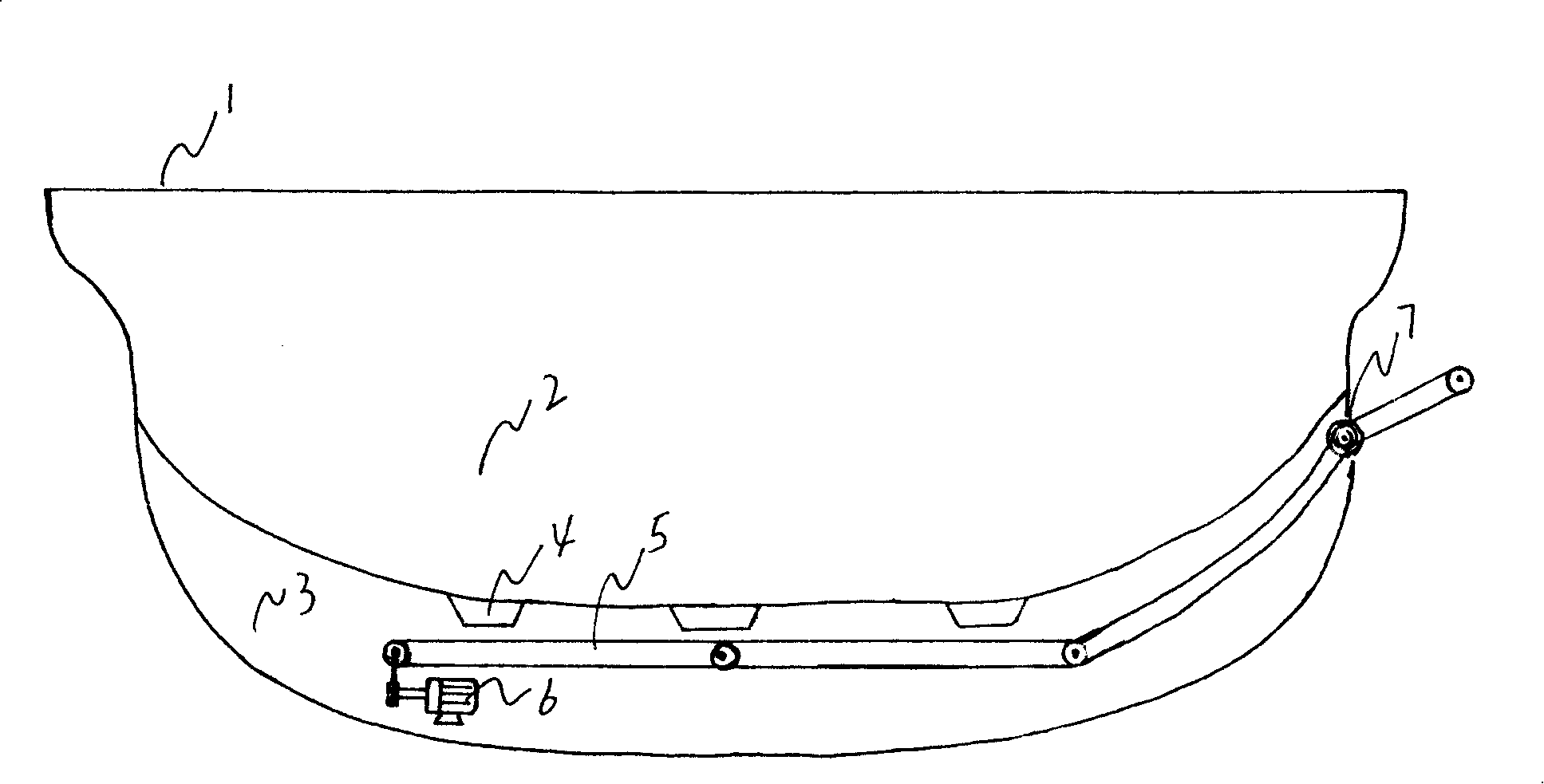

[0009] Embodiment 1: with reference to attached figure 1 . Self-unloading bulk cargo ship, the bulk carrier 1 ship warehouse is composed of a cargo warehouse 2 and a bottom warehouse 3, and the bottom warehouse of the cargo warehouse 2 is provided with 1 row or 2 rows or multiple rows with multiple controllable discharge openings 4 longitudinally or horizontally. Below the controllable discharge port 4 is the power transmission mechanism 5, the controllable discharge port 4 is an electric control type switch discharge port or an electromagnetic control type switch discharge port or a mechanical control type or hydraulic control type switch discharge port, which can be The opening size of the 4 doors of the controllable discharge port is controlled by the control mechanism. The opening of the controllable discharge port 4 is a single door or a double door or a flip door, that is to say, the controllable discharge port 4 adopts a single door or The double-leaf door or revolving...

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, the self-unloading method of the bulk material of the self-unloading bulk carrier. The bulk material is loaded in the warehouse. One or two or more controllable discharge openings in one row or two or more rows and the size of the opening of the controllable discharge openings. The control discharge port falls into the conveyor belt of the power transmission mechanism, and the conveyor belt will continuously transport the bulk materials to the agreed place or the shore under the action of the power drive machine and the transmission transmission mechanism. The control mechanism shuts itself off. The opening or opening of one or two or more controllable discharge port doors in one or two or more rows at the bottom of the warehouse are all controlled by the control mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com