Thin film manual quick bonding device

A film and bonding technology, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems that affect the film conveying and packaging quality, affect the production efficiency of packaging equipment, and uneven surface, so as to shorten the replacement of film rolls The effect of improving the time of the drum, improving the surface quality of the film, and improving the quality of conveying and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

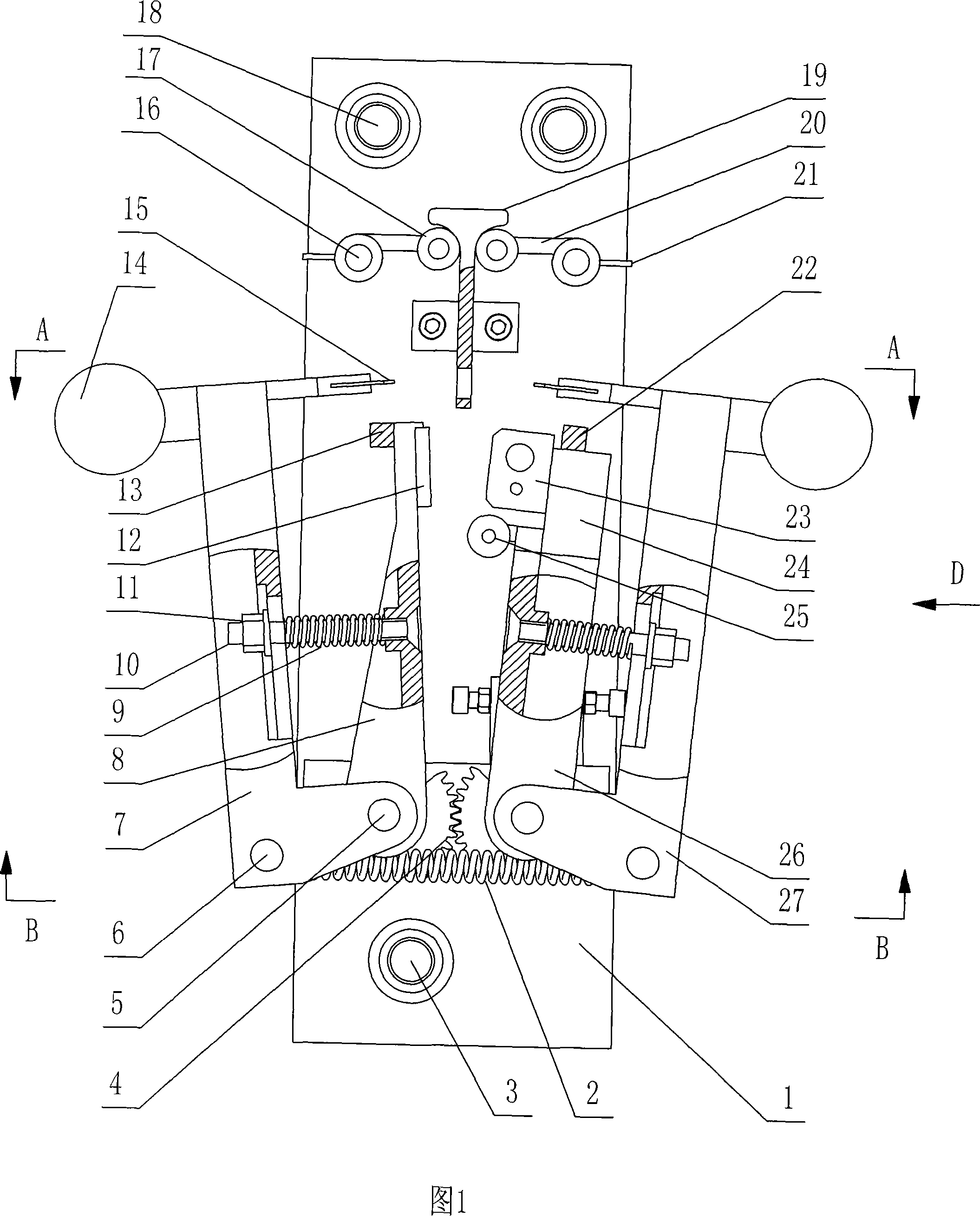

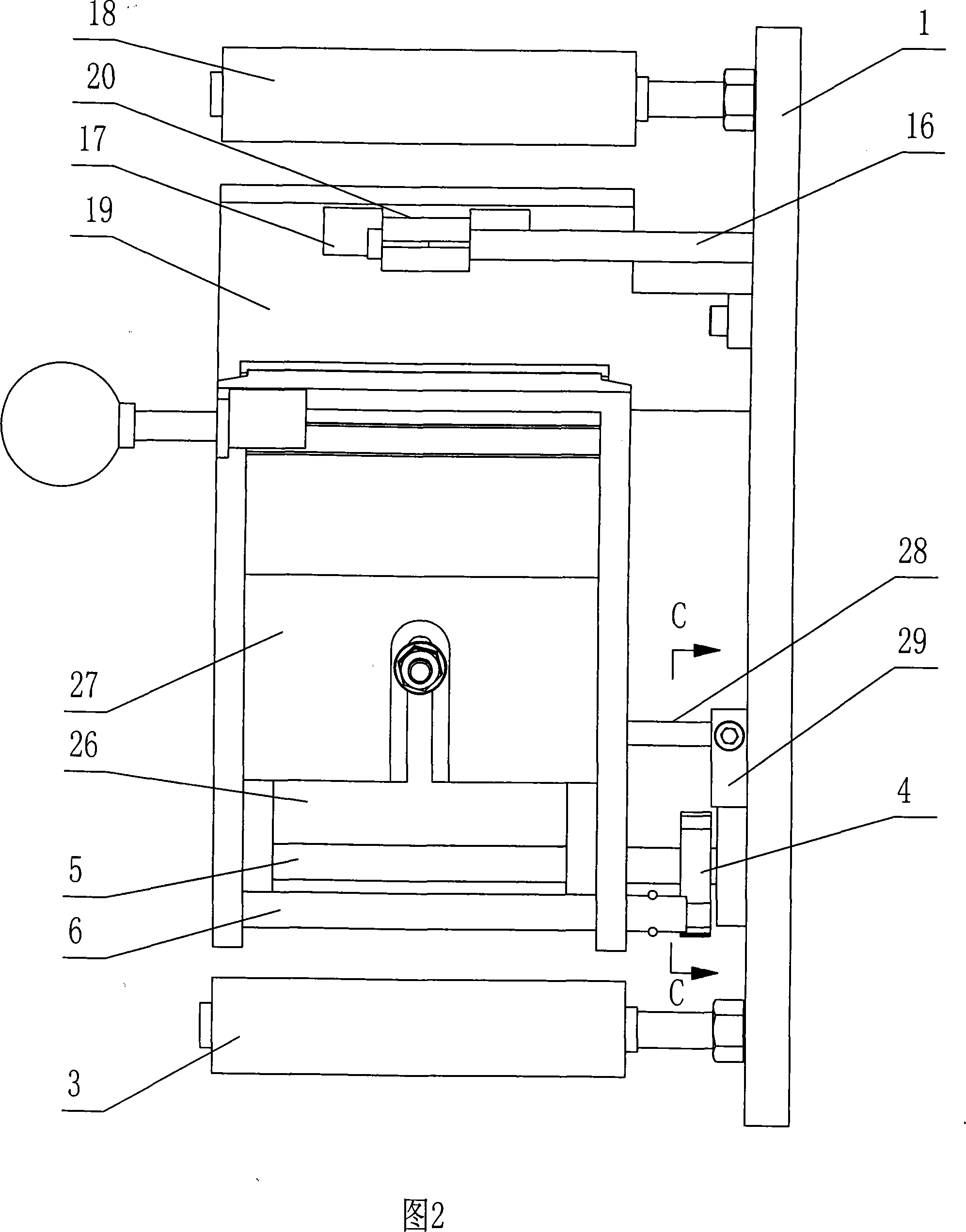

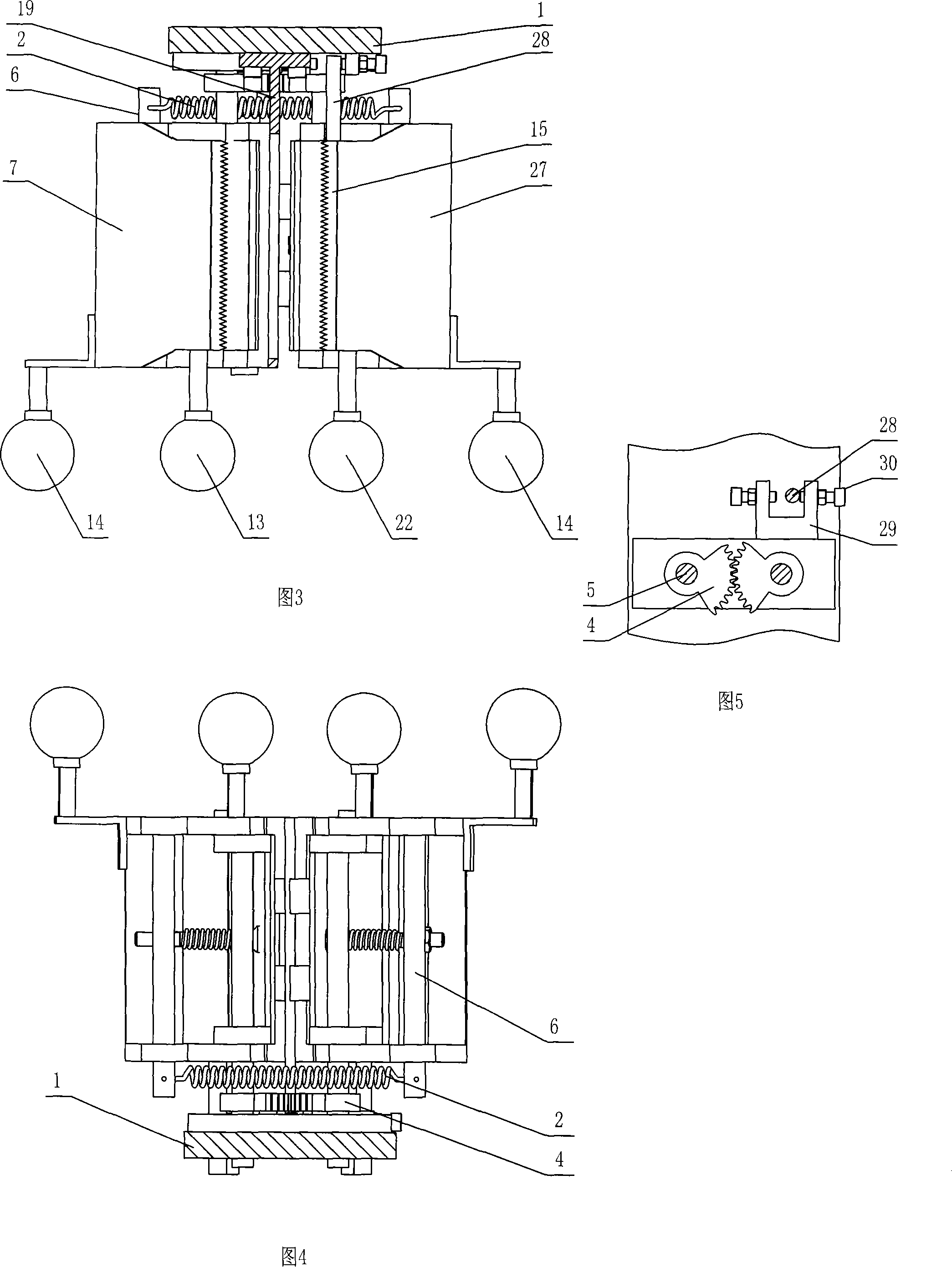

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It includes a rectangular vertical plate 1, the vertical plate is the base of the device, and input rollers 18 are symmetrically arranged on both sides above the vertical plate for the introduction of the film. One end of the input roller is connected with the vertical plate, and the other end hangs outward. Out, a film-guiding and clamping mechanism is arranged below the middle of the two input rollers, and the film-guiding and clamping mechanism includes a film-guiding plate 19 with a T-shaped cross-section, and arc surfaces are arranged on both sides of the inner surface of the upper end of the film-guiding plate. The two sides of the membrane plate are equipped with a swing clamping roller assembly. The swing clamping roller assembly is composed of a support rod shaft 16, a return swing rod 20 connected to it, and a swing rubber roller 17 installed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com