Intensified heat transfer pipe

A heat transfer tube and tube body technology, applied in the field of enhanced heat transfer tubes, can solve problems that have not yet been seen, and achieve the effects of improving heat transfer coefficient, strengthening condensation heat transfer, and increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

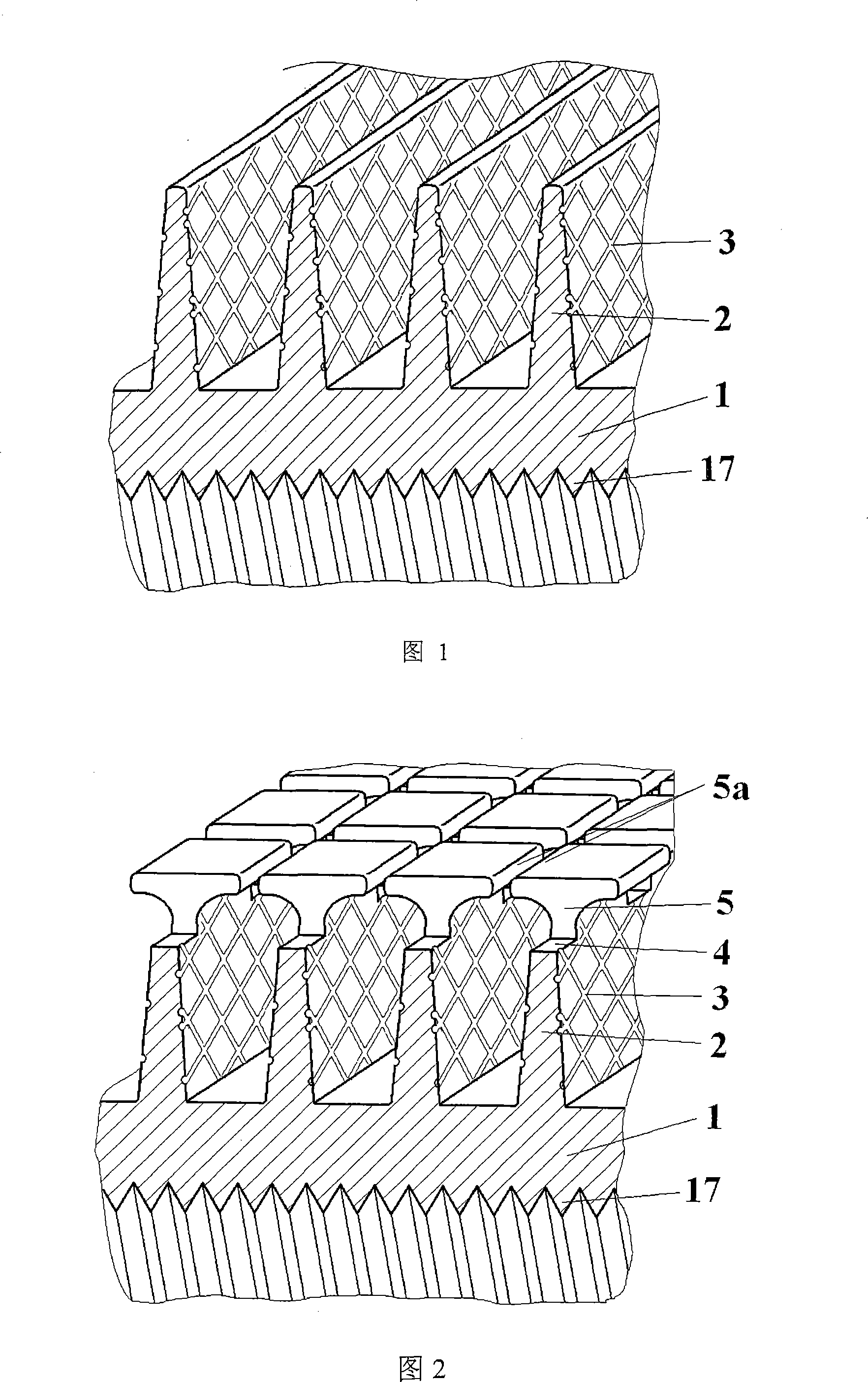

[0029] Please see Fig. 1, the outer fin 2 is formed and rolled on the outer wall of the tube body 1 with the inner fin 17 at one time, and a kind of enhanced heat transfer tube is produced. The outer fin 2 is made of the material on the tube body 1 along the tube The body 1 is formed by extending outward in the radial direction, and is an integral structure with the pipe body 1. There is a contact thermal resistance between them. The outer fins 2 extend spirally around the pipe body 1 on the outer surface of the pipe body 1; At the same time as the outer fins 2, dense micro-scale grooves 3 are processed on the side surface of the outer fins 2 by a cutter. These micro-scale grooves 3 are micro-scale groove slotting knives 9 (shown in Figures 3 and 4) A cluster of dense curves is drawn when the outer fin 2 is rotated relative to the outer fin 2. On both sides of the outer fin 2, the cluster of curves forms a grid-like structure. The micro-scale channels 3 of the grid-like structu...

Embodiment 2

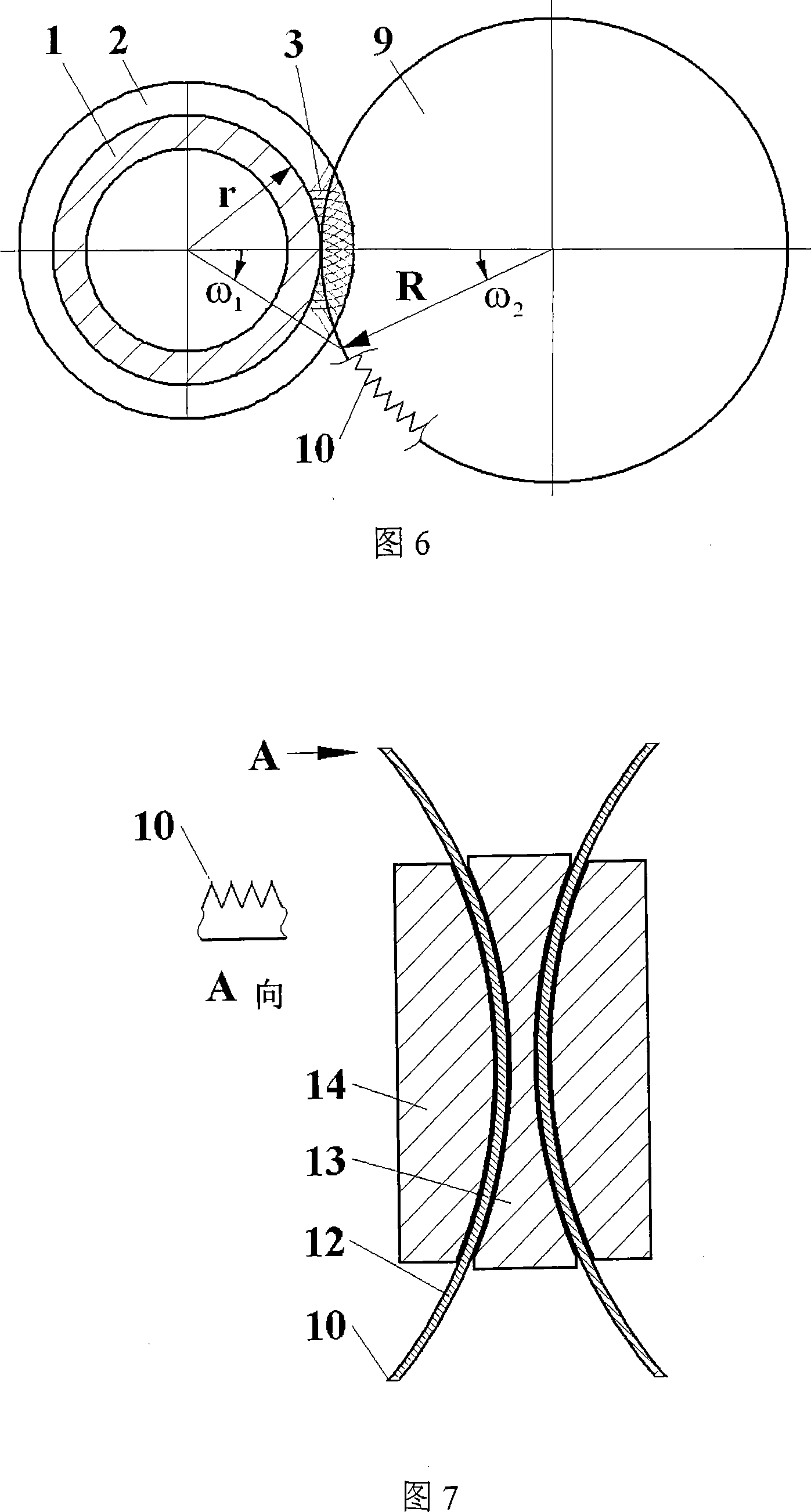

[0033]Please see Fig. 3 and Fig. 6, equipped with outer fin grooving knife 7, outer fin forming knife 8 and micro-scale channel grooving knife 9, and install this group of cutters on the tool holder 16 (also called cutter shaft) Above, among them, the edge of the micro-scale channel slotting knife 9 is uniformly provided with a plurality of knife edges 10 (shown in Figure 6), and the outer fin 2 is processed and formed on the tube body 1 by extrusion method at one time, and the typical size is The diameter of the tube body 1 at the root of the outer fin 2 is 20mm. During the relative rotation between the tube body 1 and the above-mentioned cutter, the outer fin 2 with a height of 2mm is formed by the outer fin slotting knife 7 and the outer fin forming knife 8, and at the same time, the micro-scale channel slotting knife 9 The knife edge 10 (shown in FIG. 6 ) marks regular micro-scale grooves 3 with a groove width of 0.08 mm, a groove depth of 0.05 mm, and an average groove di...

Embodiment 3

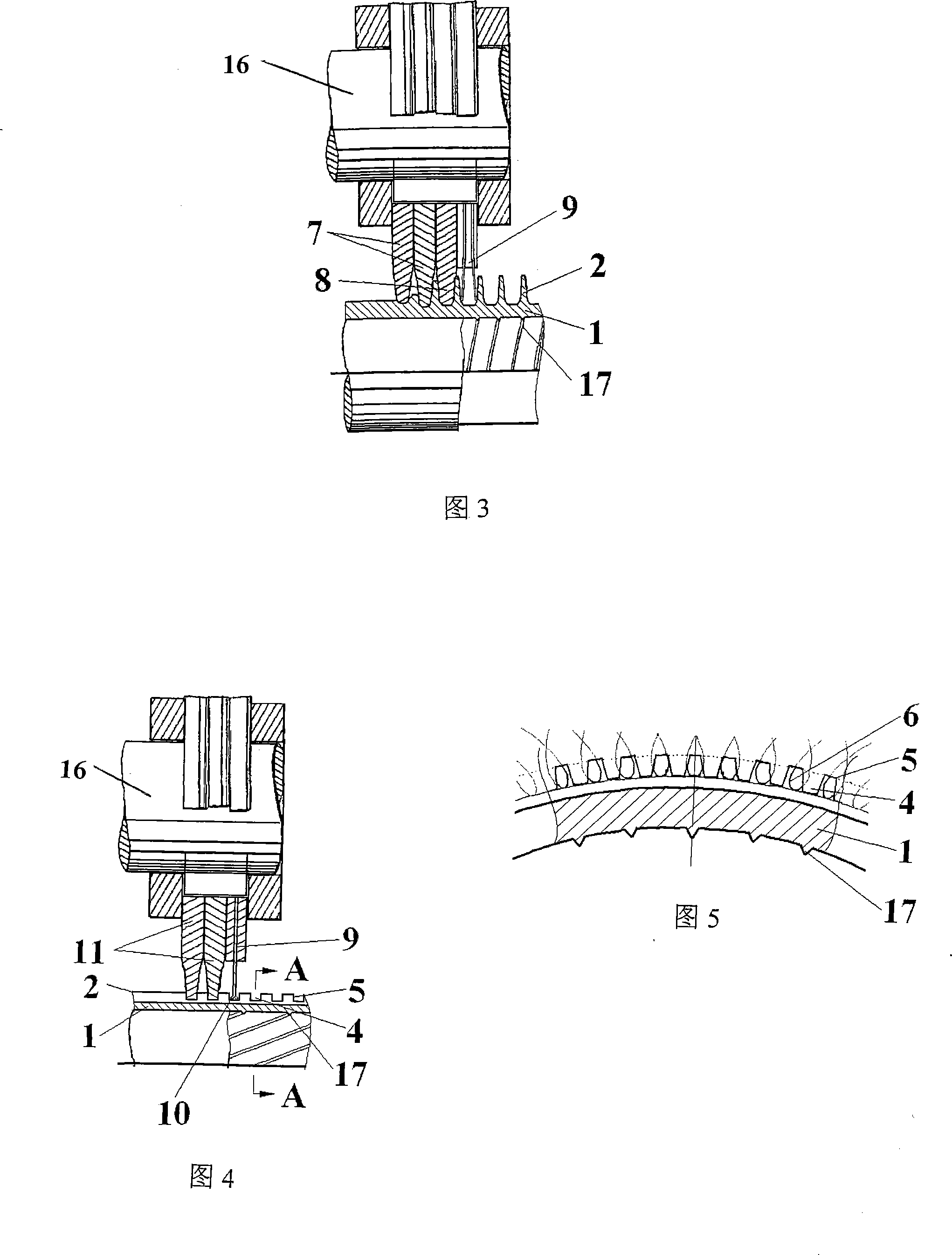

[0047] Please refer to FIG. 4 and FIG. 5 in conjunction with FIG. 2 , taking the example of making the enhanced heat transfer tube of the present invention used as a condensation tube and shown in FIG. 2 .

[0048] The specific structure includes a tube body 1, an outer fin 2 formed on the outer wall of the tube body 1, a groove 4 is cut out on the outer fin 2, a tooth platform 5 is formed between two adjacent grooves 4, and the groove 4 The depth of the outer fin 2 is less than the height of the outer fin 2. The groove 4 and the tooth platform 5 form the outer fin 2 in a zigzag shape. There are 1 to 2 lines on the surface of the tooth platform 5 opposite to the groove 4 from the root of the tooth platform 5 to the top. Extended arc-shaped micro-scale channels 6 (shown in Figure 5) and micro-scale channels 3 are formed on the side surfaces of both sides of the outer fin 2. The groove width of the scale channel 3 and the arc-shaped micro-scale channel 6 are 0.05mm and 0.01mm re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com