Dam safety sensing optic cable

A technology of sensing optical cable and sensing optical fiber, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of no water blocking layer, failure of optical cable, poor resolution of dam crack leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

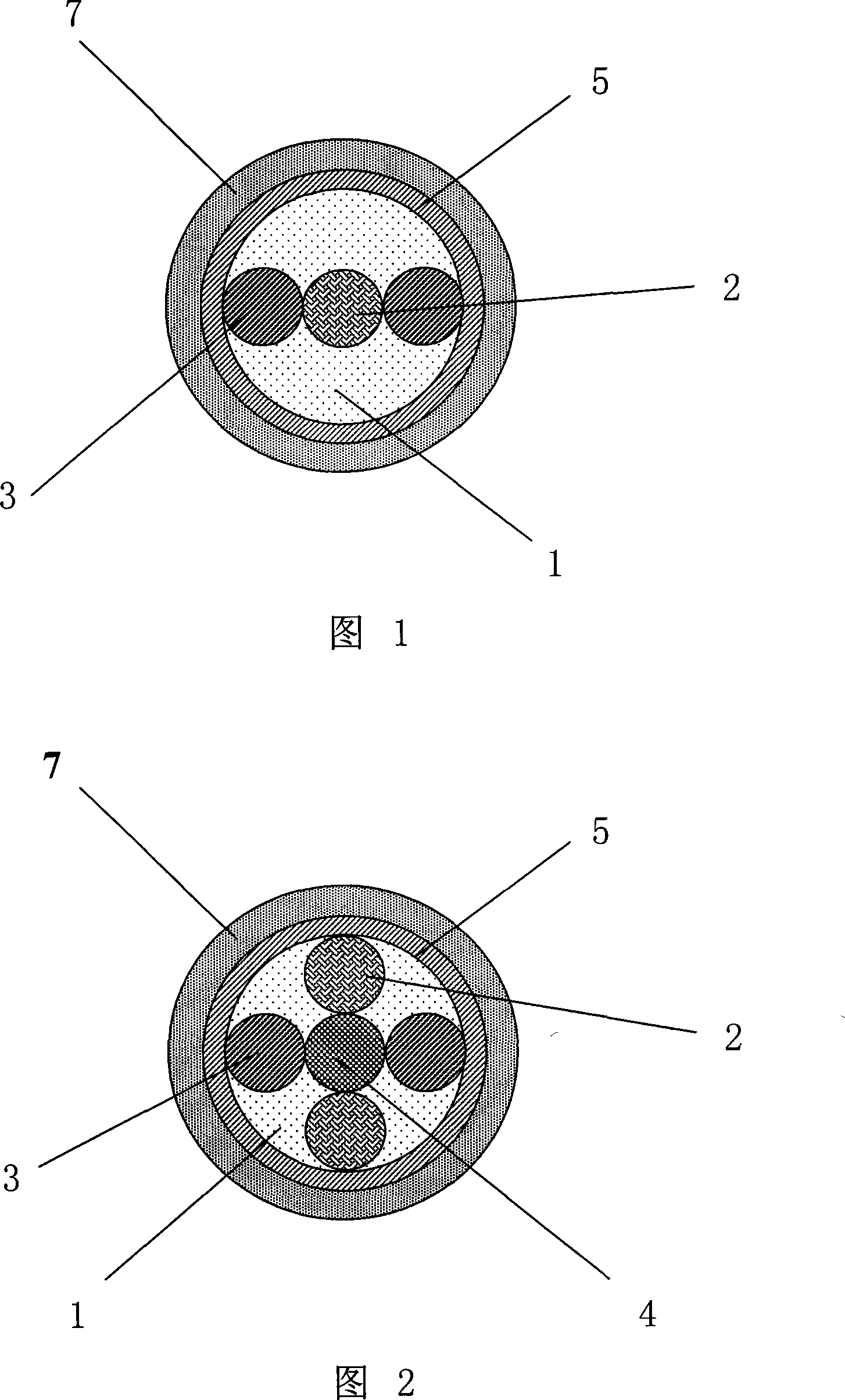

Embodiment 1

[0008] Embodiment 1: With reference to Fig. 1. In this embodiment, one sensing optical fiber is used, and the length of the two wires in the present invention is sufficient to form a certain (heating) internal resistance when an operating voltage is applied to both ends of the wires. The present invention can be laid (layer by layer) during the construction of the dam, and whether there is leakage inside the dam structure can be monitored by the present invention after the dam is completed. First, short-circuit one end of the two wires, then apply a working voltage (20-30V DC voltage) to the other end of the two wires, and make the two wires generate heat according to the internal resistance of the two wires, and at the same time make the present invention The temperature rises to a certain temperature, and then the power is cut off to transmit the heat data of the present invention to the terminal measuring instrument installed on the data processing host in the room for meas...

Embodiment 2

[0009] Embodiment 2: with reference to Fig. 2. In this embodiment, a sensing optical fiber and a reinforcing rib are added on the basis of Embodiment 1, and the reinforcing rib is arranged at the position of the sensing optical fiber in the first embodiment, and 2 sensing optical fibers are arranged on both sides of the reinforcing rib. When one of the sensing optical fibers fails or breaks, the safety monitoring of the dam can still be realized, and the compressive strength of the invention can be improved.

Embodiment 3

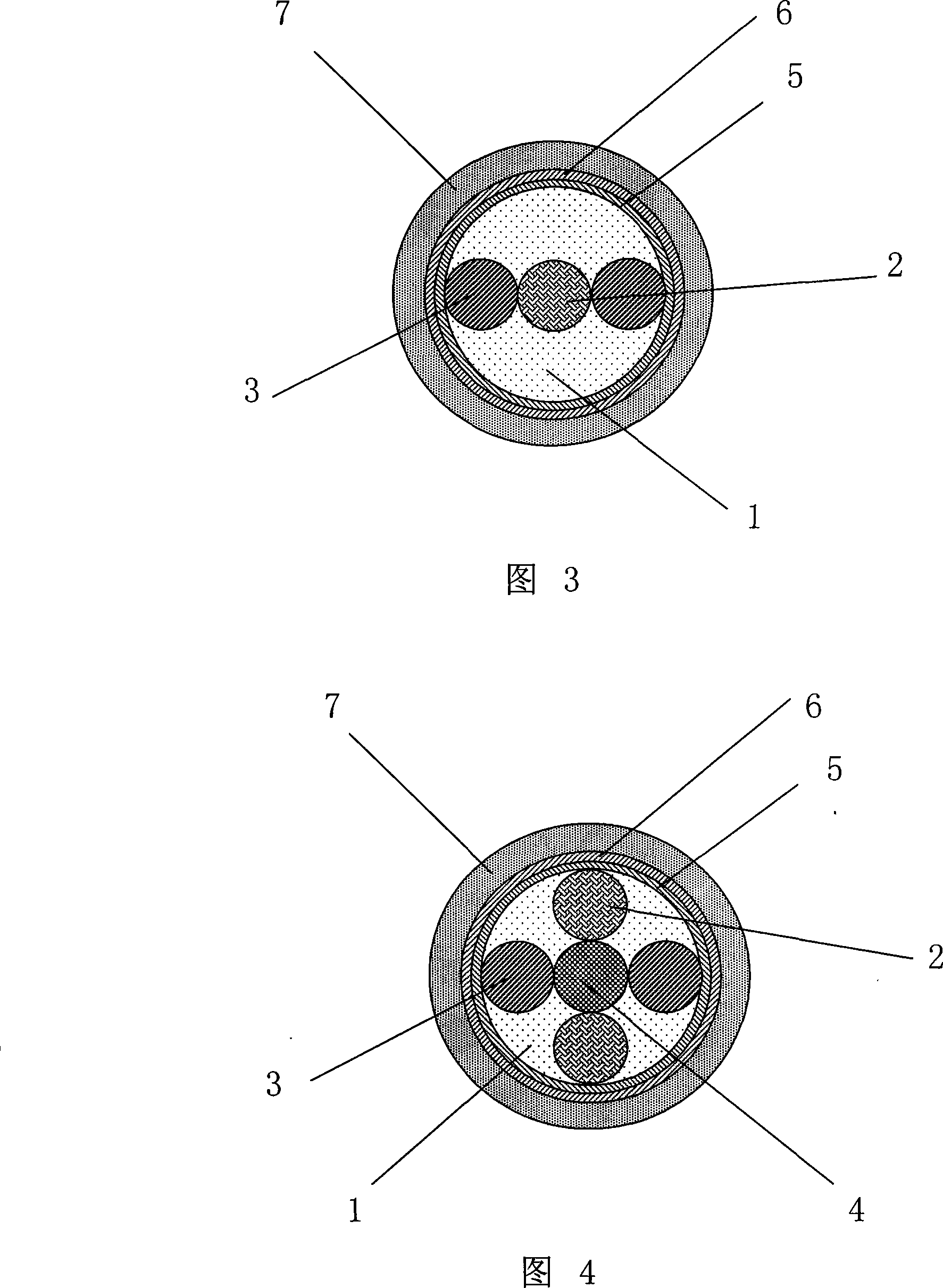

[0010] Embodiment 3: With reference to Fig. 3. In this embodiment, on the basis of embodiment 1, a water-blocking layer is filled between the reinforcing sleeve and the sheath, so that water vapor erosion can be prevented while realizing the safety monitoring function of the dam, and the service life of the present invention is prolonged. To achieve better implementation effect of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com