Low-noise lead

A low-noise, wire-based technology used in conductors, non-insulated conductors, power cables, etc. to achieve light weight, prevent wind noise, reduce corona sound and radio interference levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

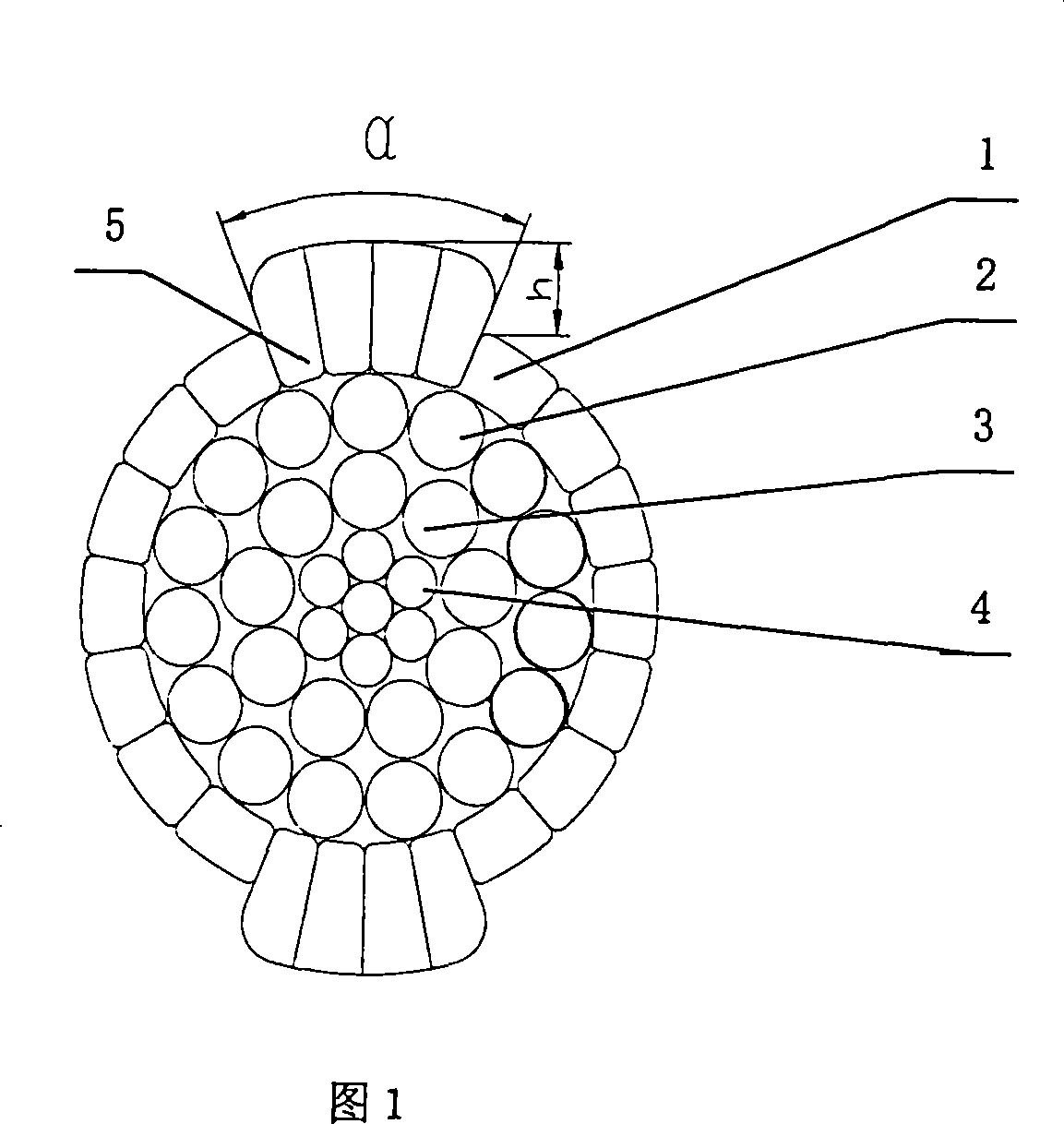

[0009] Referring to Figure 1 , the low-noise wire structure includes a load-carrying core 4 , a conductor 3 , a conductor 2 and a conductor 1 . A conductor 3, a conductor 2, and a conductor 1 are arranged outside the carrying core 4, and the conductor 3 and the conductor 2 are single wires with a circular cross section; the conductor 1 is a single wire with a special-shaped cross section, which is the outermost conductor, and the outermost conductor adopts a trapezoidal cross section aluminum wire strands. In the conductor 1, some single wires with special-shaped cross-sections are higher than other single wires with special-shaped cross-sections, and certain protrusions 5 are formed on the surface of the conductors, and the protrusions have a certain opening angle. As for the height h of the protruding part of the wire is 2.3-2.7mm, the opening angle α of the protruding part is 30°-120°.

[0010] The conductor can be made of duralumin, or rare-earth aluminum alloy, or alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com