High-strength vacuum insulation plate

A vacuum insulation board, high-strength technology, applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve the problems of poor strength of the board body, damaged structure, etc., and achieve good high temperature resistance, low thermal conductivity, and high strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

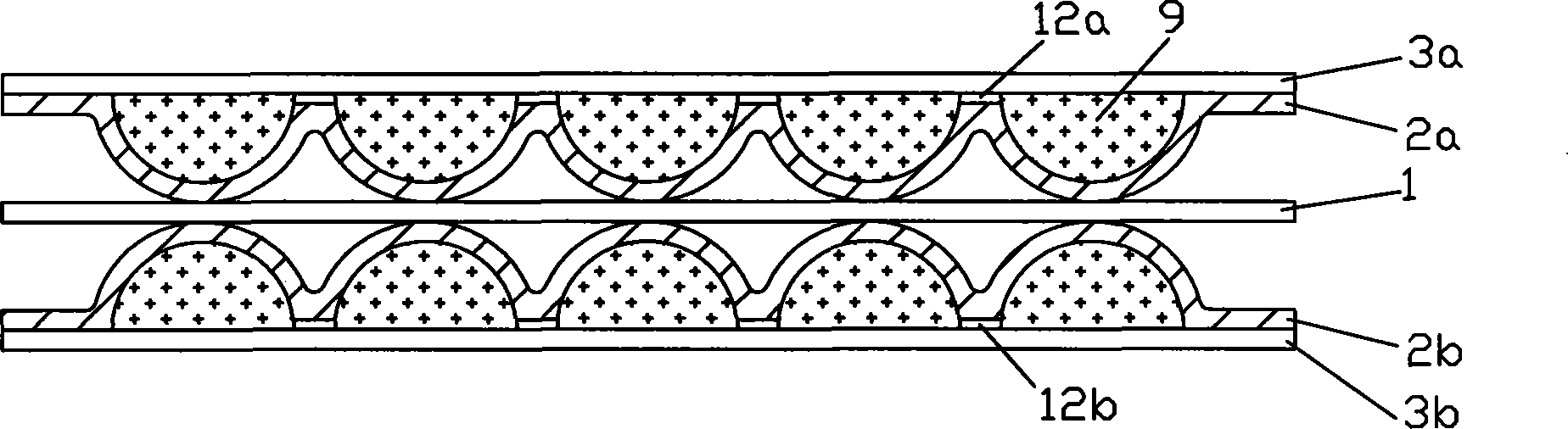

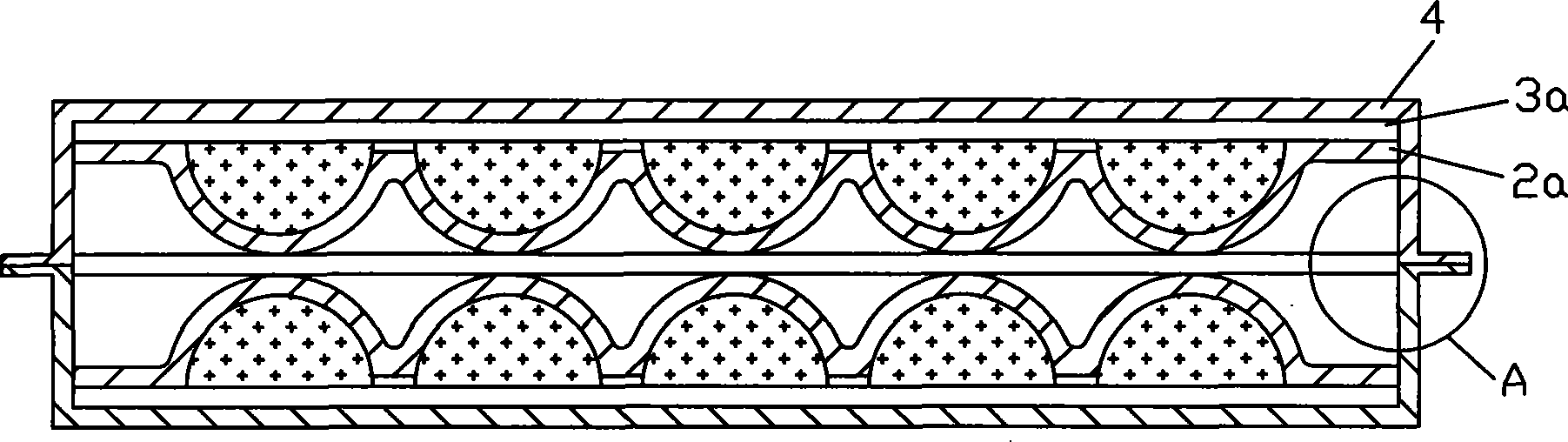

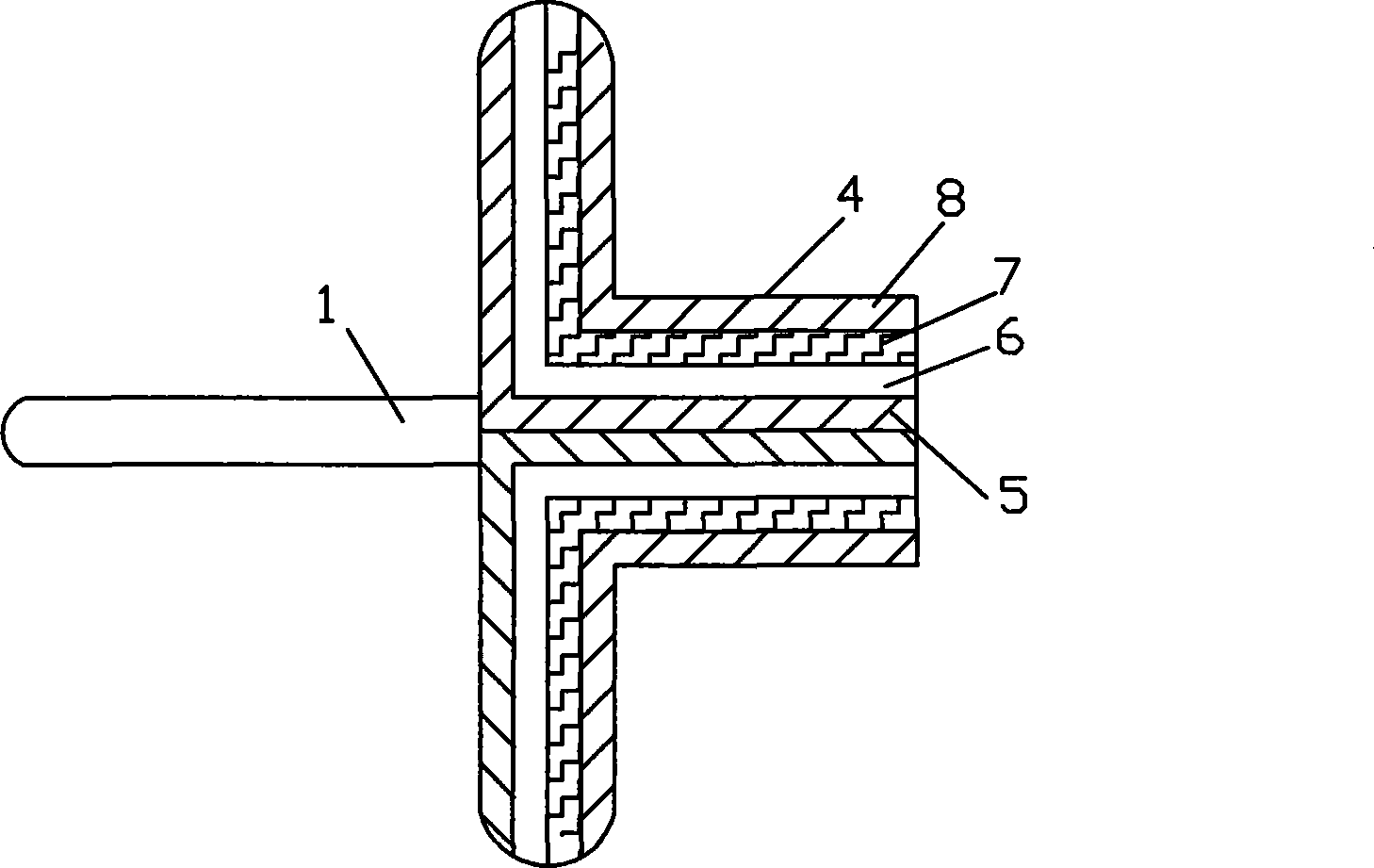

[0028] see figure 1 , 2 The high-strength vacuum insulation panel of the present invention includes a vacuum shell bag 4 and an insulating core material arranged in the vacuum shell bag. The heat insulating core material includes an intermediate insulating layer 1, and the two sides of the intermediate insulating layer 1 are plates with several hemispherical depressions. 2a and plate 2b, the side of plate 2a and plate 2b facing away from the middle insulation layer 1 is respectively pasted with infrared reflective layer 3a and infrared reflective layer 3b, and the hemispherical depressions of plate 2a and plate 2b are filled with silica airgel 9 .

[0029] The several hemispherical depressions of the board 2a and the board 2b are regularly arranged, and the ball tops of the hemispherical depressions face the middle insulation layer 1, and the board 2a and the board 2b are made of phenolic resin.

[0030] A communication groove 12a is formed in the non-recessed part between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com