Pigment granulation product relative hardness detecting instrument

A detector and granulation technology, which is applied in the direction of testing the strength of materials using a single impact force, can solve the problems of human and financial resources, pollution of the environment, and easy generation of dust by powder pigments, and achieve the effect of saving financial and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

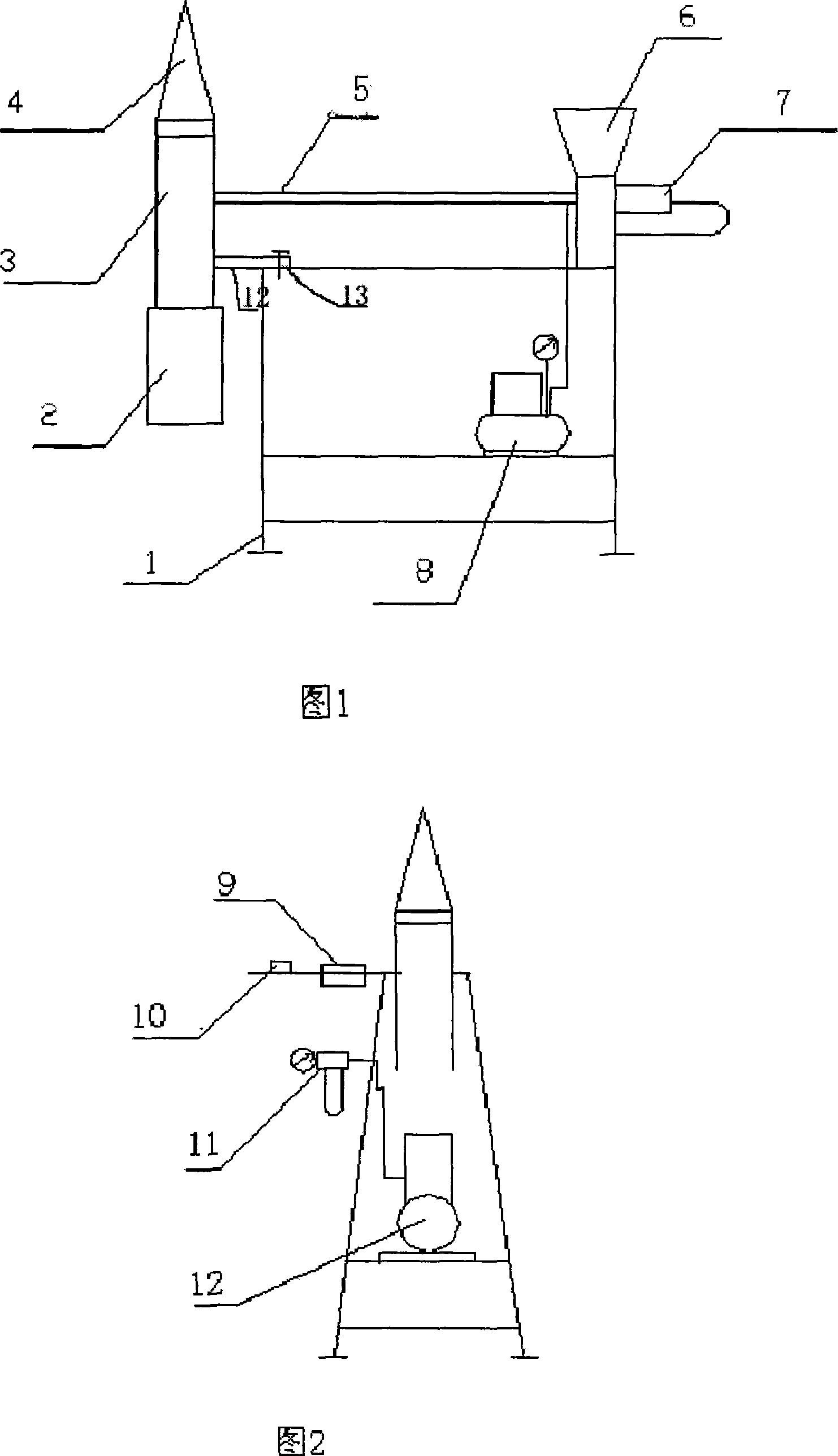

[0016] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0017] As shown in Figure 1, a schematic diagram of the structure of a relative hardness tester for pigment granulation products, including a test bracket 1 and a material switch 7, one end of a constant pressure constant flow tube 5 with compressed air is provided with a feeding port 6, and the other end is provided with There is a crash box 3, the top of the crash box 3 is a pressure relief net 4, and the bottom thereof is a material collection bag 2. The box wall of the crash box 3 is a thick metal plate. The constant pressure and constant flow pipe 5 through which compressed air is connected is connected with an air pump 12 controlled by an air flow device 8 . The air flow device 8 includes a solenoid valve 9 , a start switch 10 , and a pressure regulating valve 11 . The impact box 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com