Capacity-expanding main circuit of railway train AC traction electric motor

A technology of traction motor and main circuit, which is applied in the field of electric transmission, can solve the problems of affecting the whole running speed, the safety and reliability of the running capacity, affecting the running capacity and speed of the whole running, insufficient regenerative and resistance braking power, etc. Moving distance, less investment, reducing the effect of coordination and cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

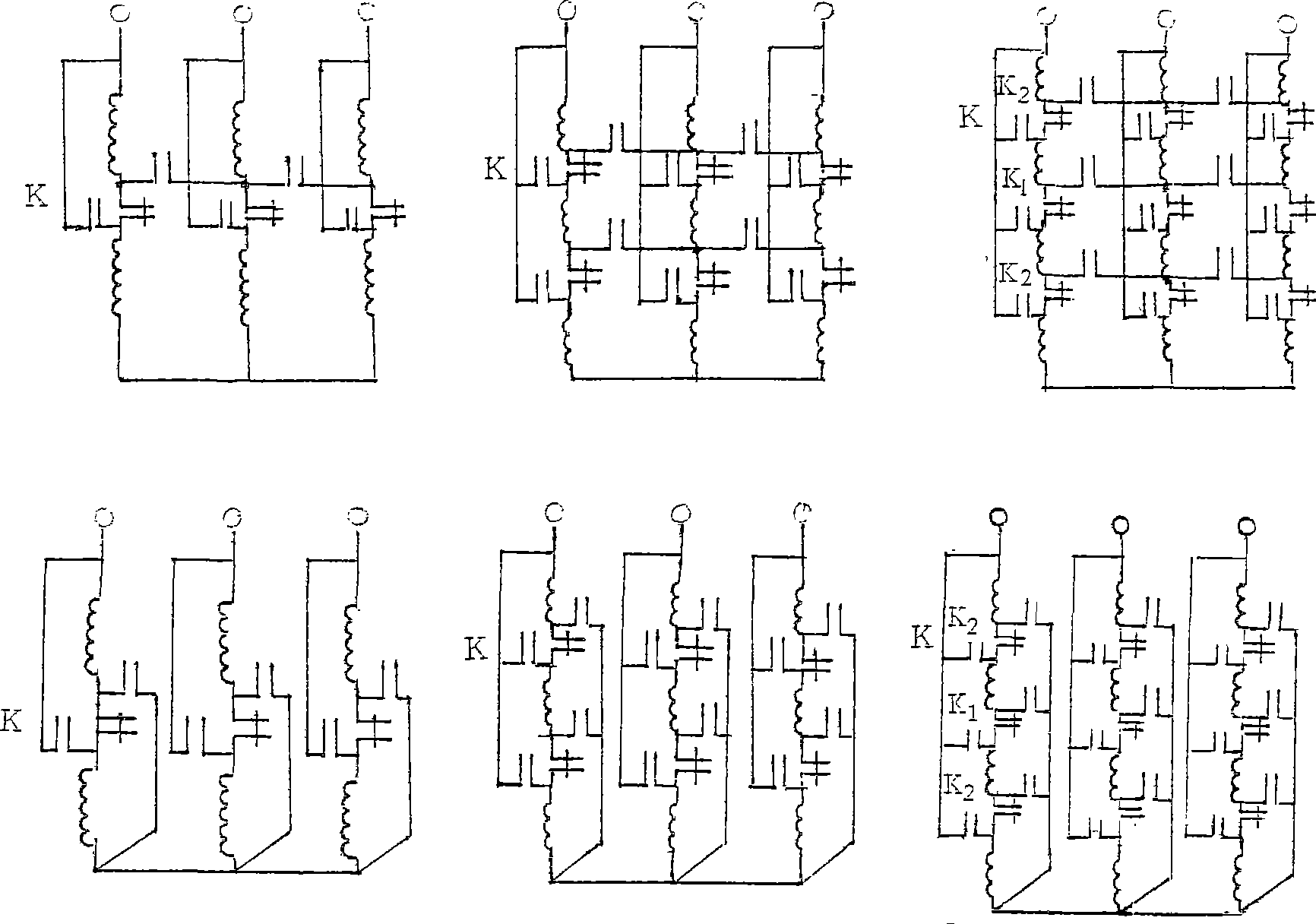

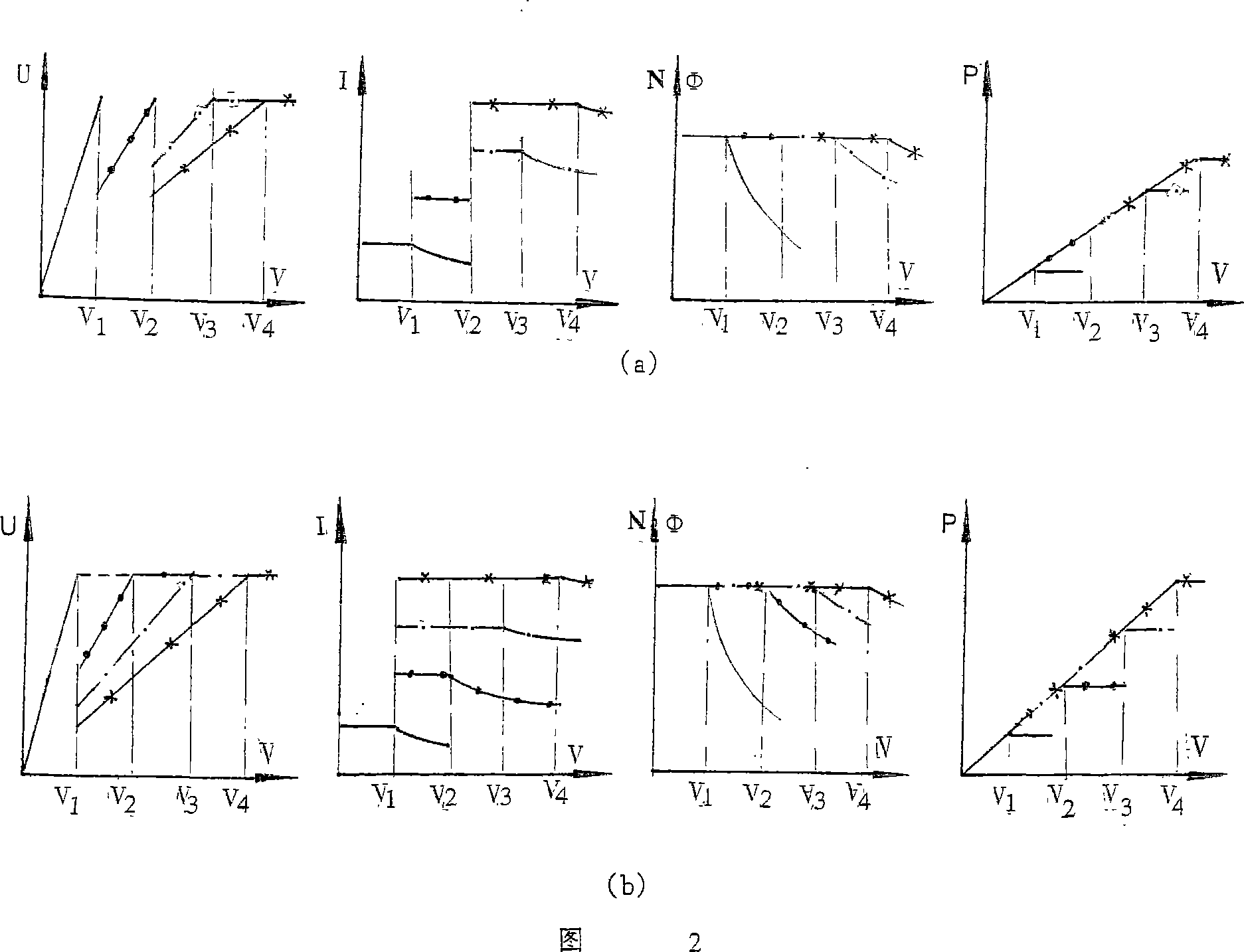

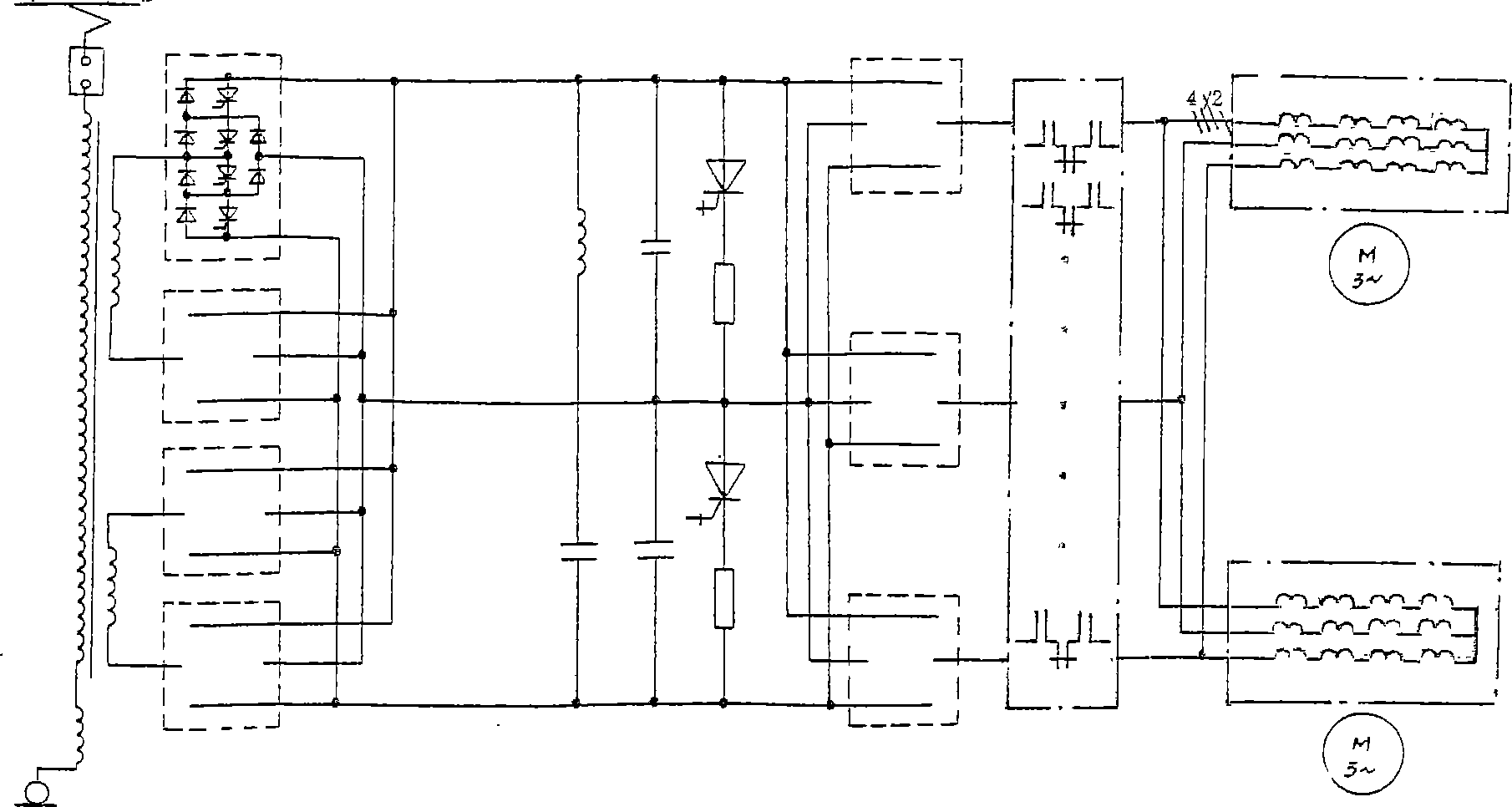

[0031] 1. Trunk expansion electric locomotive using three-point converter, see appendix image 3 The main circuit

[0032] A main converter supplies power to two parallel 4-pole asynchronous traction motors M, each motor has 4 pole-phase groups per phase, and the leads of each phase are 1-8, 11-18, 21-28; Between the current transformer and the traction motor, consider adding an axle-type transfer switch with arc contacts to the LCC (Fig. 5). String → 2 and see the first axis, lead wires 5, 8 are connected to 2 static contacts, 1, 4 are connected to the normally open moving contact, 4 is connected to the normally closed moving contact; the second axis 2 parallel → 4 parallel, the lead wire 1, 2, 6, and 8 are connected with 4 static contacts, while 2, 3, 6, and 7 are connected with the normally open moving contacts; 3 and 7 are connected with the normally closed moving contacts; it is similar to them.

[0033] 1 string up to 4 parallel (b) can be carried out at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com