Discarded concrete reclaiming method and device

A technology of waste concrete, recycling method, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but not limited to the embodiments.

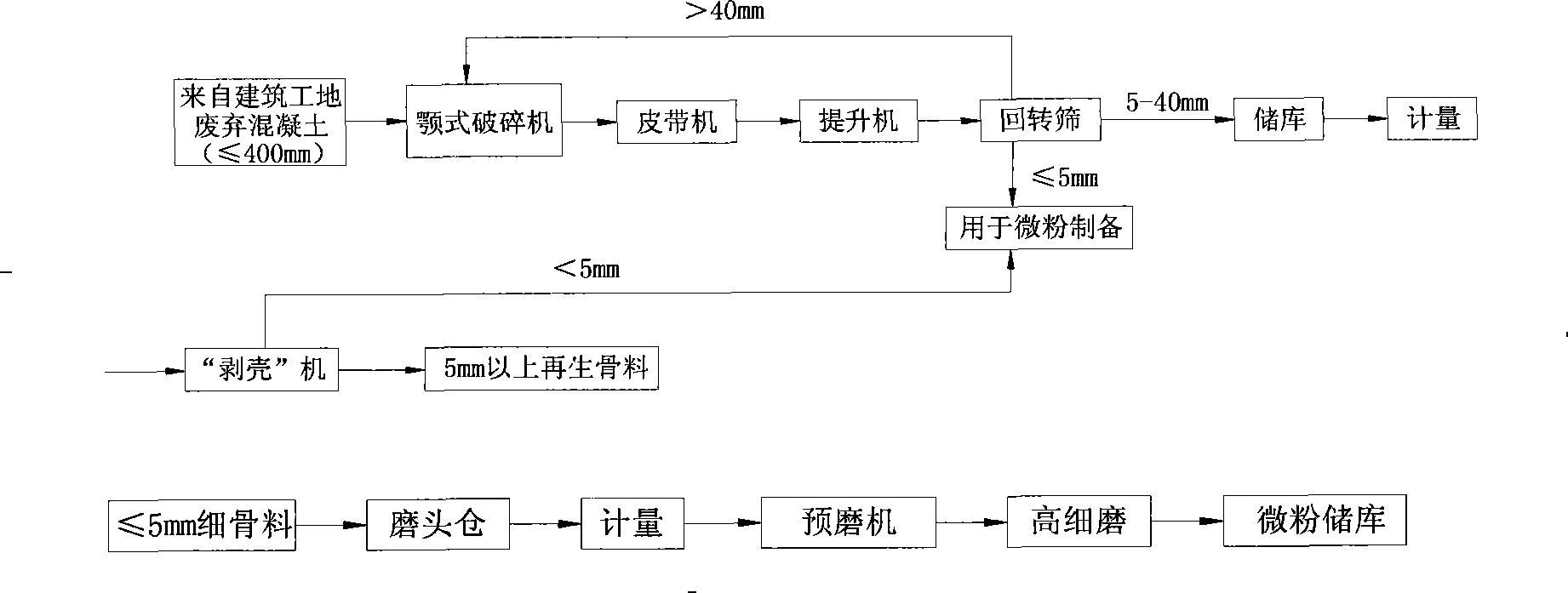

[0014] Such as figure 1 As shown: the process flow of this embodiment is: the waste concrete from the construction site (after removing the reinforcement, its particle size is about 400mm), is crushed by a common jaw crusher, and the maximum particle size of the machine is 50mm, and it is passed through the belt Machines, elevators, etc. are sent to the rotary screen for sorting, and they are divided into three particle sizes larger than 40mm, 5-40mm, and smaller than 5mm. The part larger than 40mm is sent back to the crusher for further crushing; the part of 5-40mm is ground to separate the firmly bonded coarse and fine aggregates to obtain clean stones of 5-25mm and fine aggregates smaller than 5mm; Part of the superfine grinding treatment.

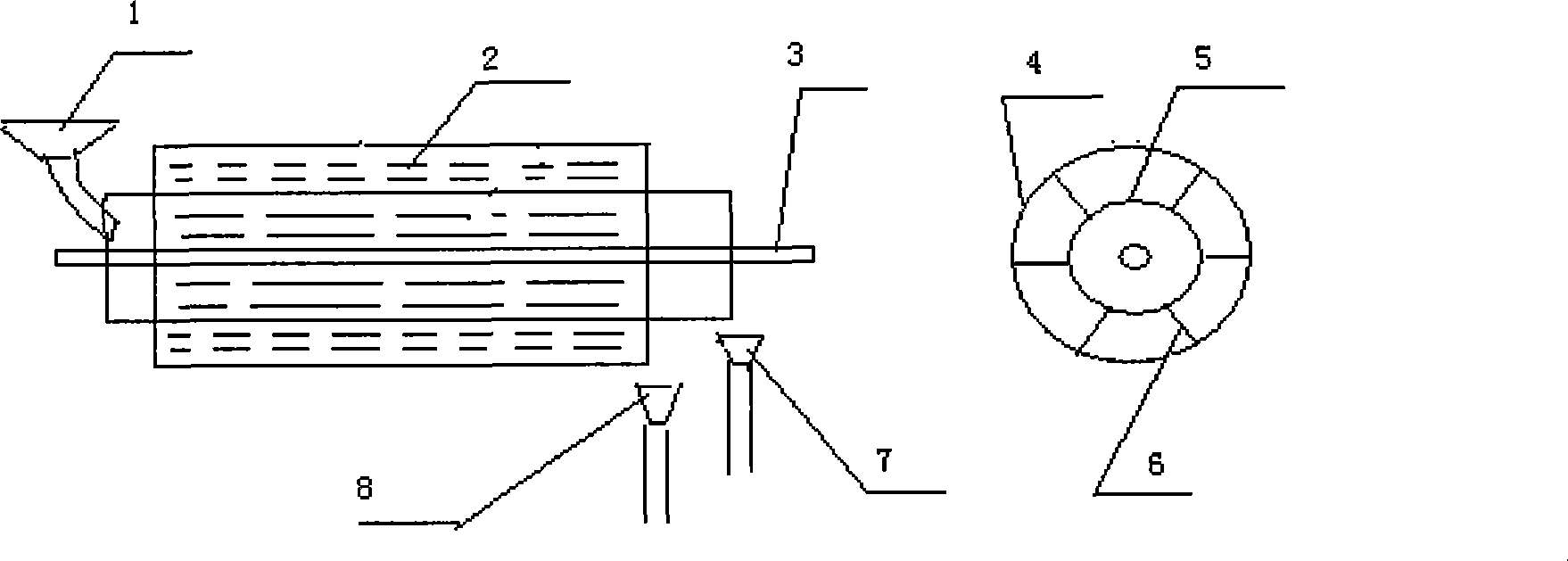

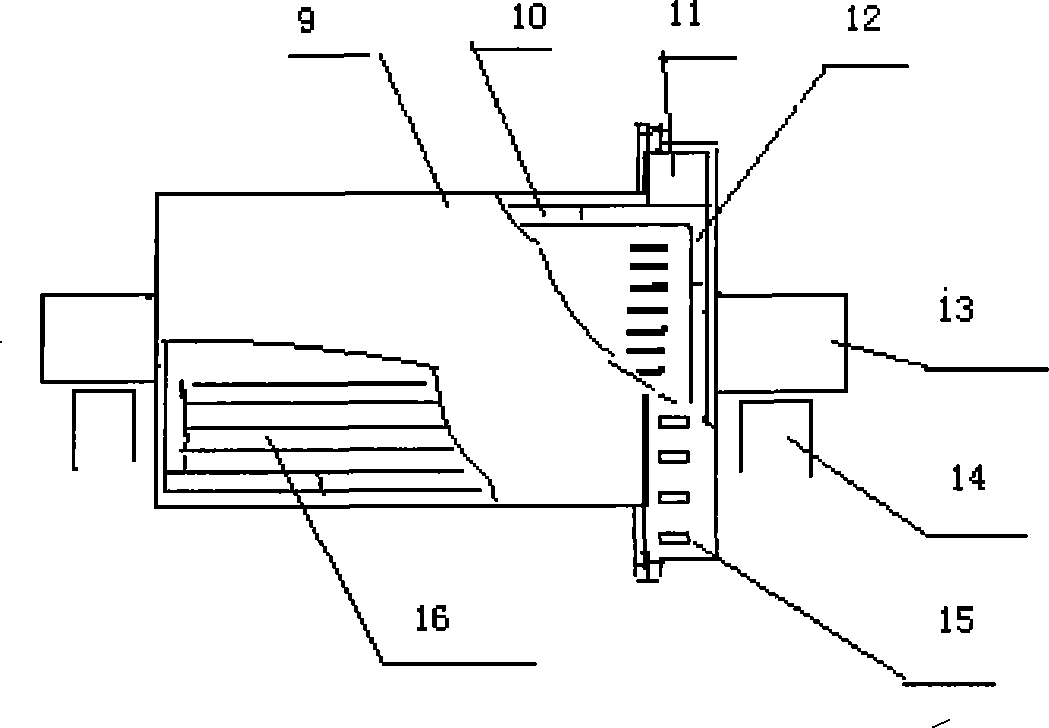

[0015] Such as figure 2 As shown, the basic structure of the rotary screen is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com