Method and special device for removing staining textile loose colour by multi-frequency ultrasound wave

An ultrasonic and fabric technology, applied in physical treatment, textile and papermaking, fiber treatment, etc., can solve the problems of not complying with energy-saving and water-saving requirements, consumption of high-temperature steam, energy consumption, and water consumption, etc., and achieve a simple structure. , reduce the amount of steam, the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0036] A method for removing floating colors from dyed fabrics by multi-frequency ultrasonic waves, the method comprises the following steps:

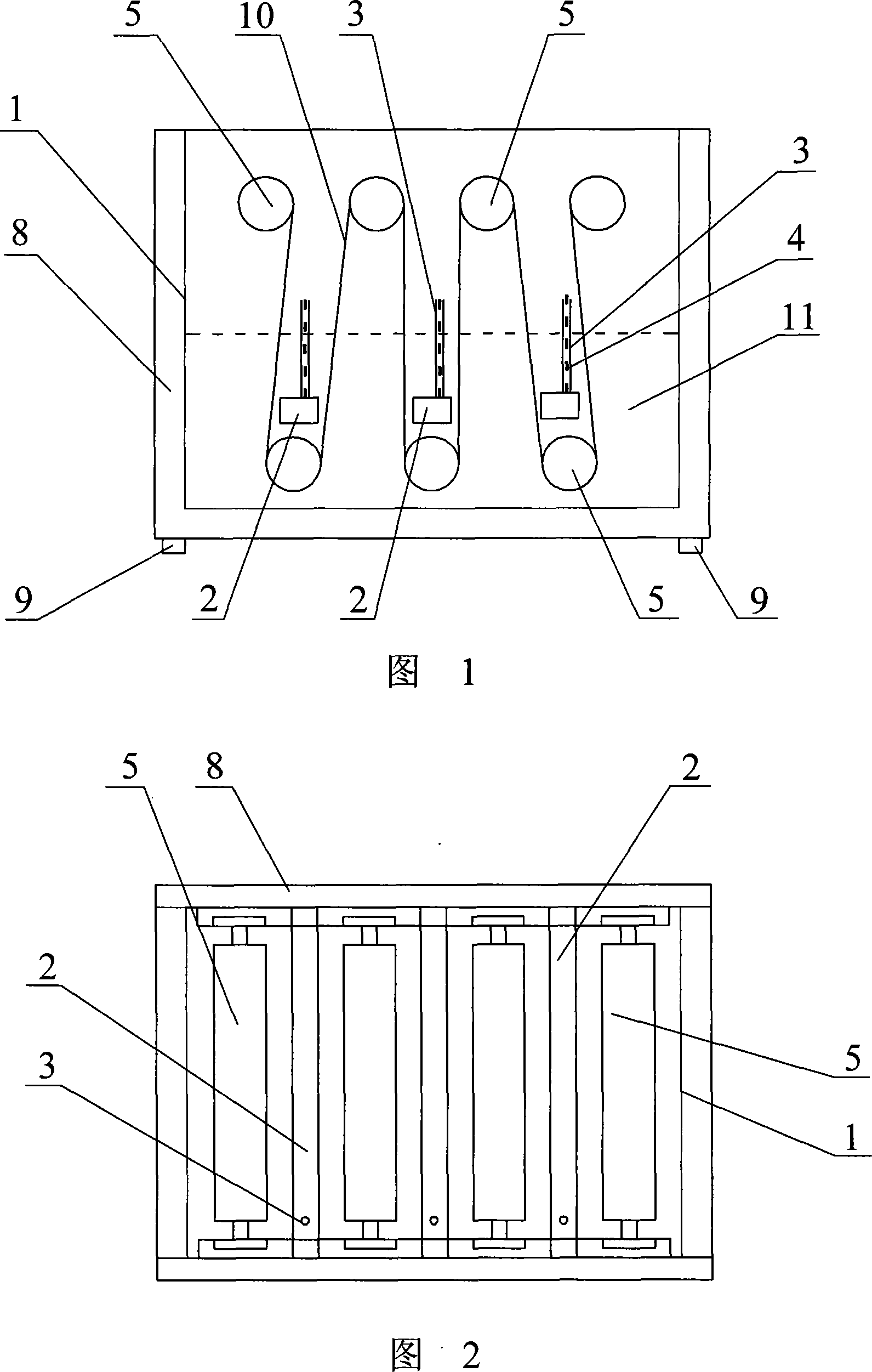

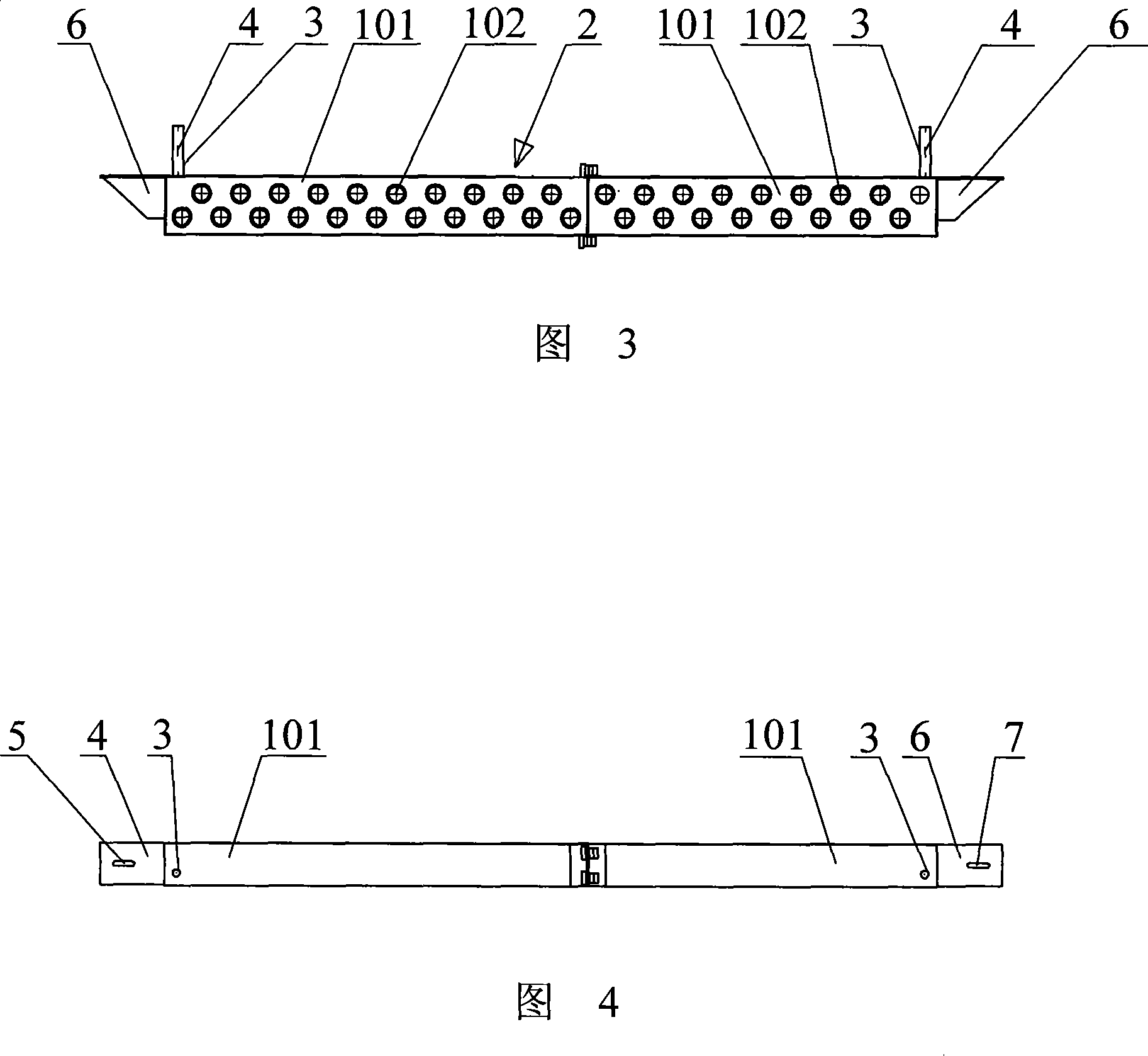

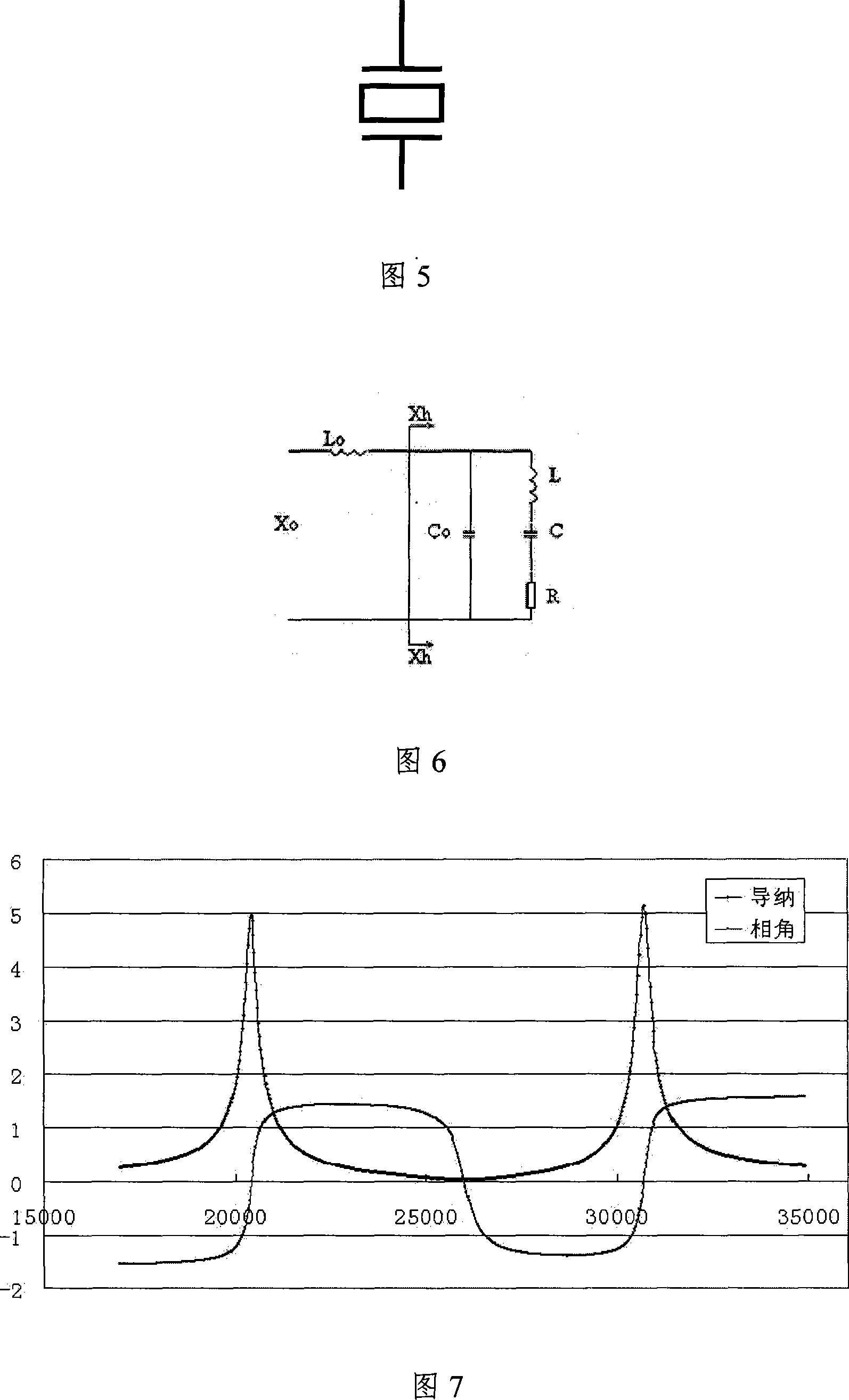

[0037] a. Install several ultrasonic vibrating boxes in the washing container. The ultrasonic frequency that each ultrasonic vibrating box can emit is 15-40KHz, and the ultrasonic frequency that each ultrasonic vibrating box can emit is different;

[0038] b. Pour washing liquid into the washing container, so that the washing liquid will submerge the ultrasonic vibration box;

[0039] c. Immerse the fabric to be washed in the washing liquid and start each ultrasonic vibration box;

[0040] d. After washing, take out the fabric.

[0041] The power ratio of ultrasonic waves emitted by any two ultrasonic vibrating boxes is a fractional multiple (such as 0.8 times) or a fractional multiple with an integer (such as 1.2 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com