Hanging device and construction method for light separating-wall hidden installation sanitary equipment

A concealed, sanitary ware technology, applied in water supply installations, indoor sanitary plumbing installations, buildings, etc., to achieve the effect of preventing cracking and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

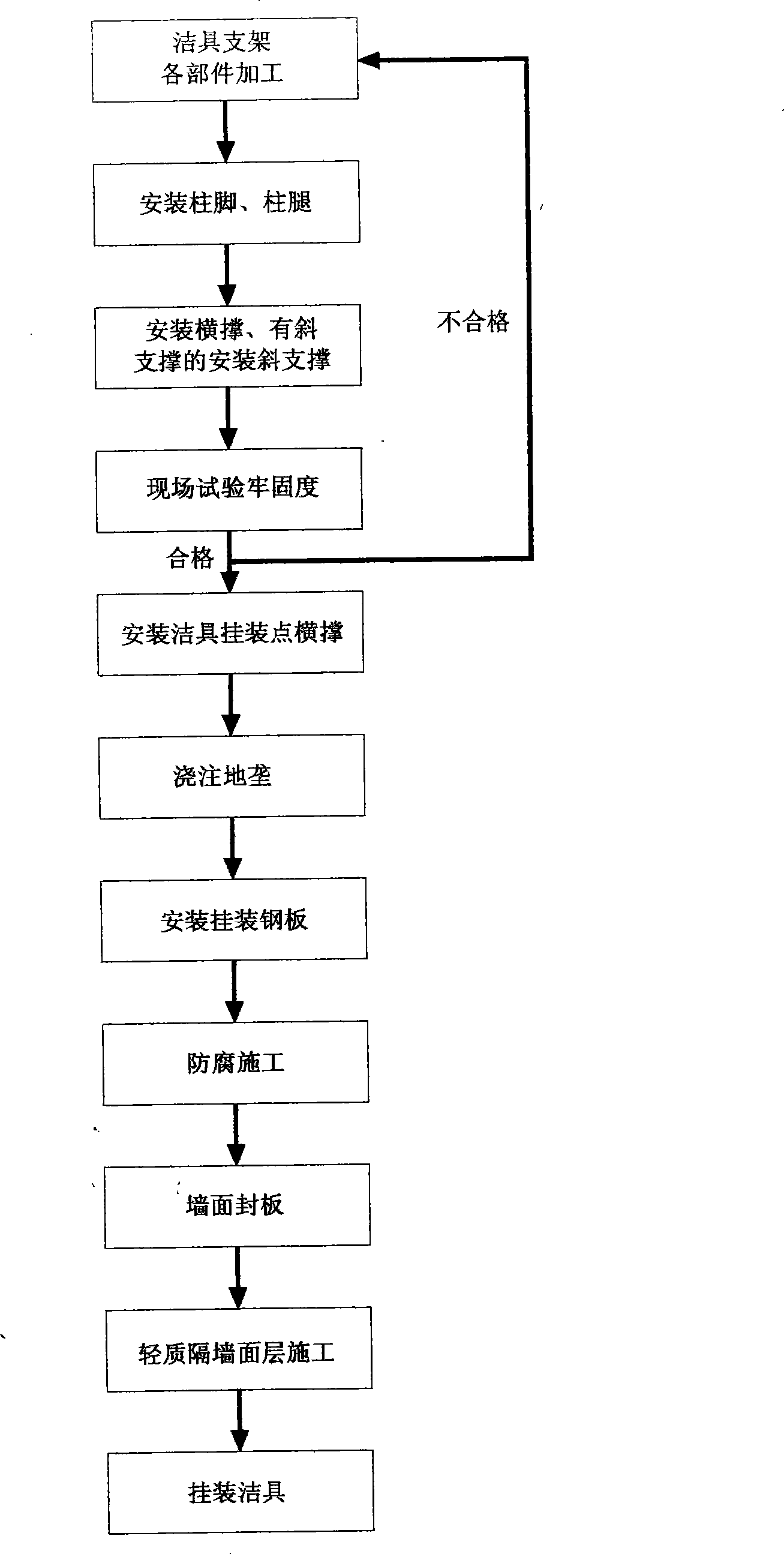

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Toilet and its flush water tank hanging device and construction method

[0056] Such as Figure 7 , Figure 8 As shown: the toilet and its flushing water tank are sanitary ware with a finished bracket 6, and the finished bracket can be purchased and sold together with the sanitary ware. It is a rectangular flat steel bracket matching the toilet and its flushing water tank. The water tank is fixed on its upper part. There is also a beam at the toilet seat.

[0057] Sanitary ware bracket 1 includes: 4 column legs 101, 4 cross braces 103, 4 column feet 102, 1 hanging steel plate 104, 2 oblique supports 105;

[0058] The bottom surface of the column leg is welded with a column foot, and the column foot is fixedly connected with the top surface of the building structure plate 3 on the floor or the ground with an expansion bolt 4 or an embedded part 5. The column leg is arranged in two layers, the outer column leg and the column foot The outside of the keel of ...

Embodiment 2

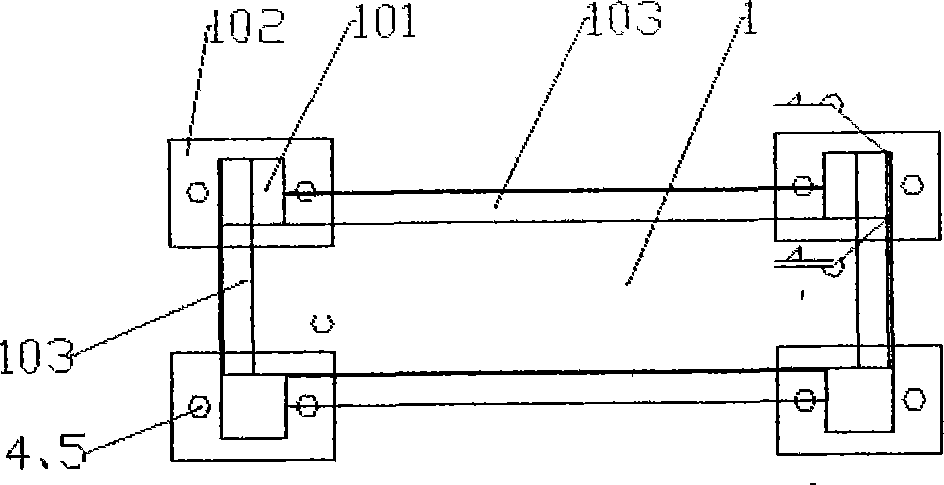

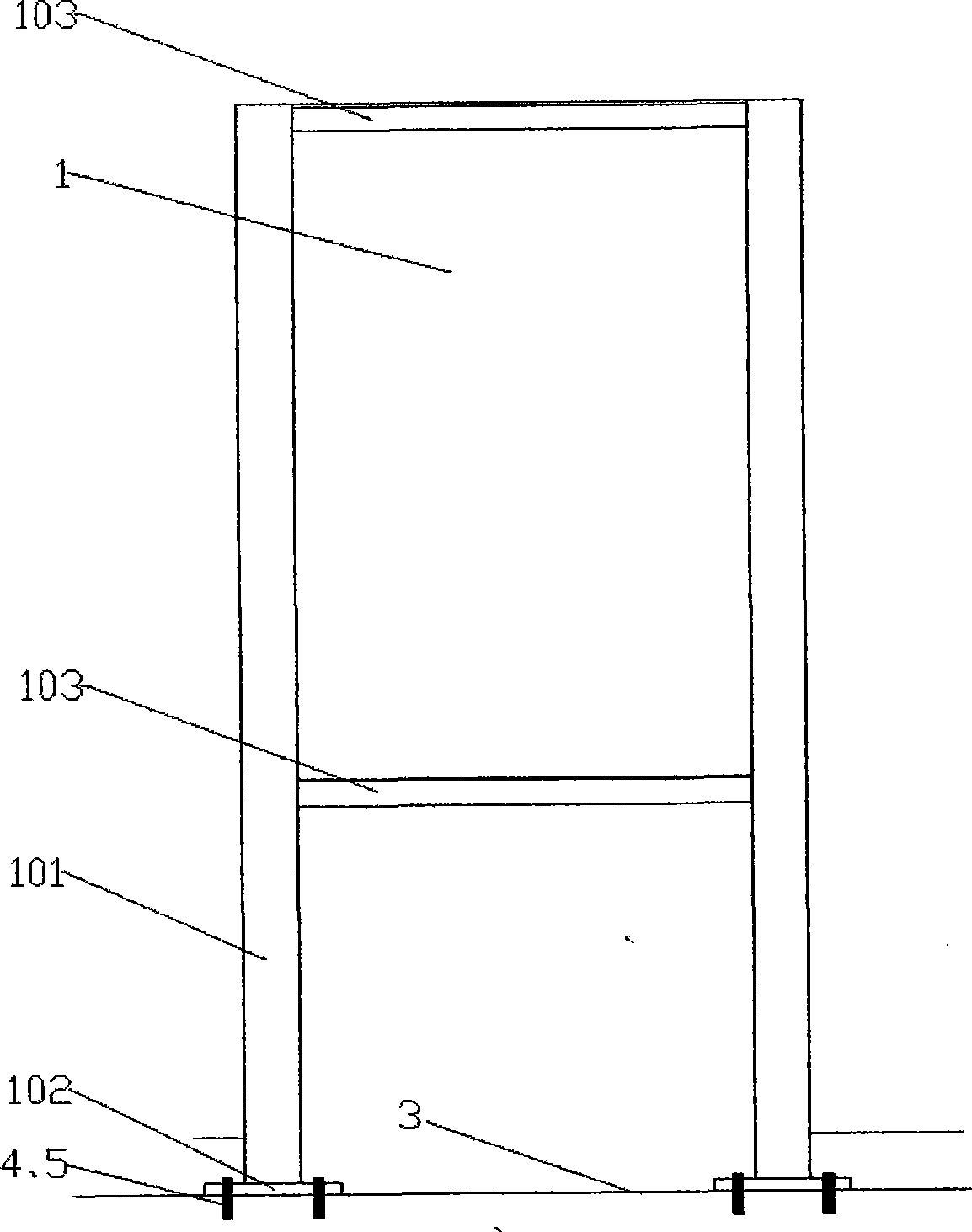

[0059] Embodiment 2: Washbasin, urinal hanging device and construction method

[0060] As shown in Figure 9 and Figure 10: washbasins and urinals are sanitary ware without finished supports, and the device includes: 4 column legs 101, 4 cross braces 103, 4 column feet 102, 1 hanging steel plate 104, 2 oblique supports 105; the bottom of the column leg is welded with a column foot, and the column foot is fixedly connected with the top surface of the building structure plate 3 on the floor or the ground with expansion bolts 4 or embedded parts 5, and the column legs are arranged according to the inner and outer layers. The top surface is welded with 4 cross braces to form a rectangular frame, which is the sanitary ware support 1. The hanging steel plate is welded on the outer surface of the outer column leg at the position where the washbasin or urinal is installed. Or the matching mounting holes or welding bolts 104A of the urinal, the washbasin or the urinal are installed on t...

Embodiment 3

[0061] Embodiment 3: Another washbasin hanging device and construction method

[0062] Such as Figure 11 As shown: the sanitary ware bracket 1 is a pure rectangular frame, and the device includes: 4 column legs 101, 4 cross braces 103, 4 column feet 102, 1 hanging steel plate 104, and no oblique support 105.

[0063] The installation of drainage and water supply pipes supporting the sanitary ware is a prior art, and it is installed after the sanitary ware support and the finished product support are installed, so no more details are given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com