System for on-line monitoring health of tippler based on optical fiber and optical grating sensing

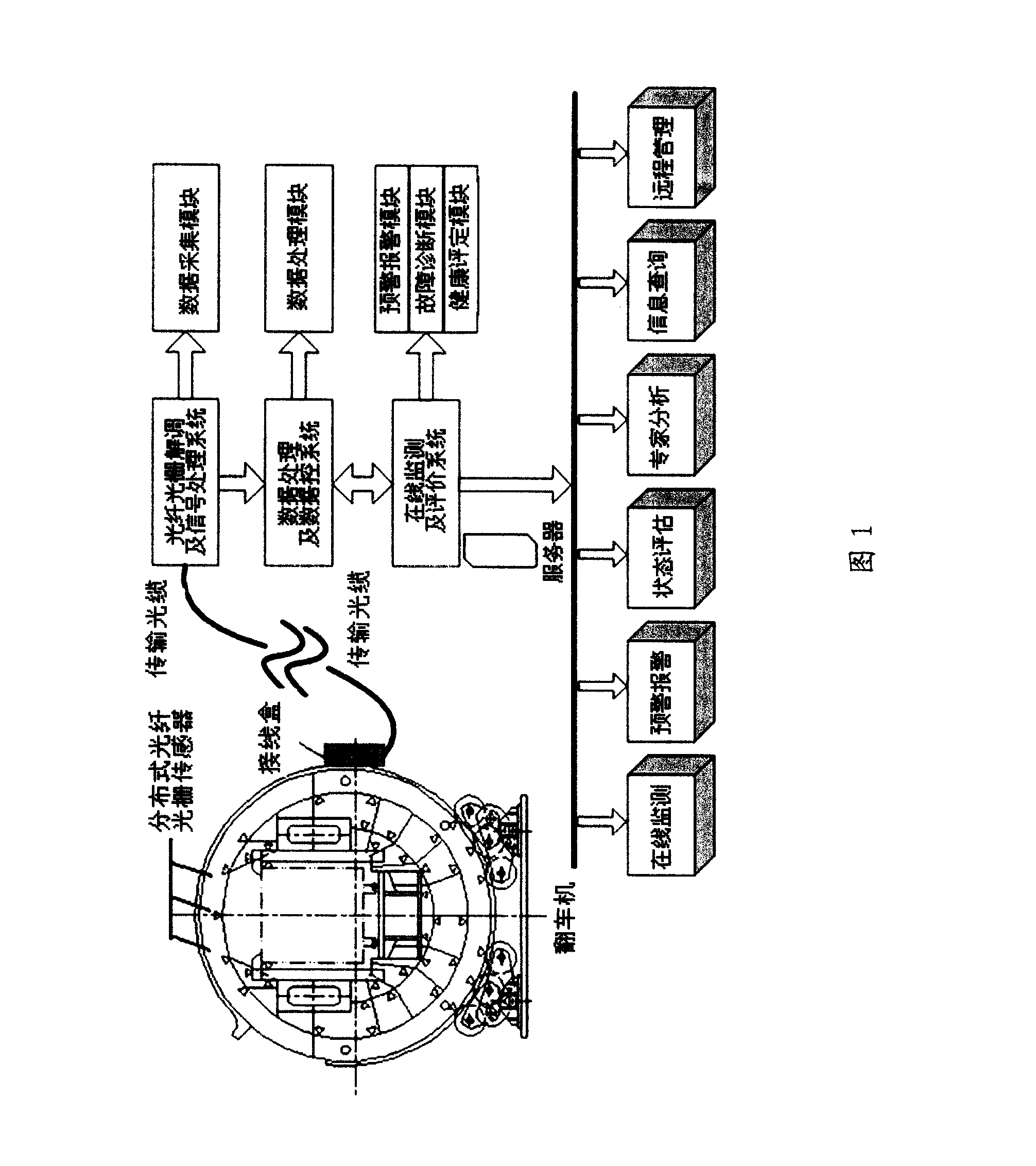

A health monitoring system and fiber grating technology, applied in the direction of using optical devices to transmit sensing components, machine/structural component testing, measuring devices, etc., can solve the problem of less application of fiber grating sensing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

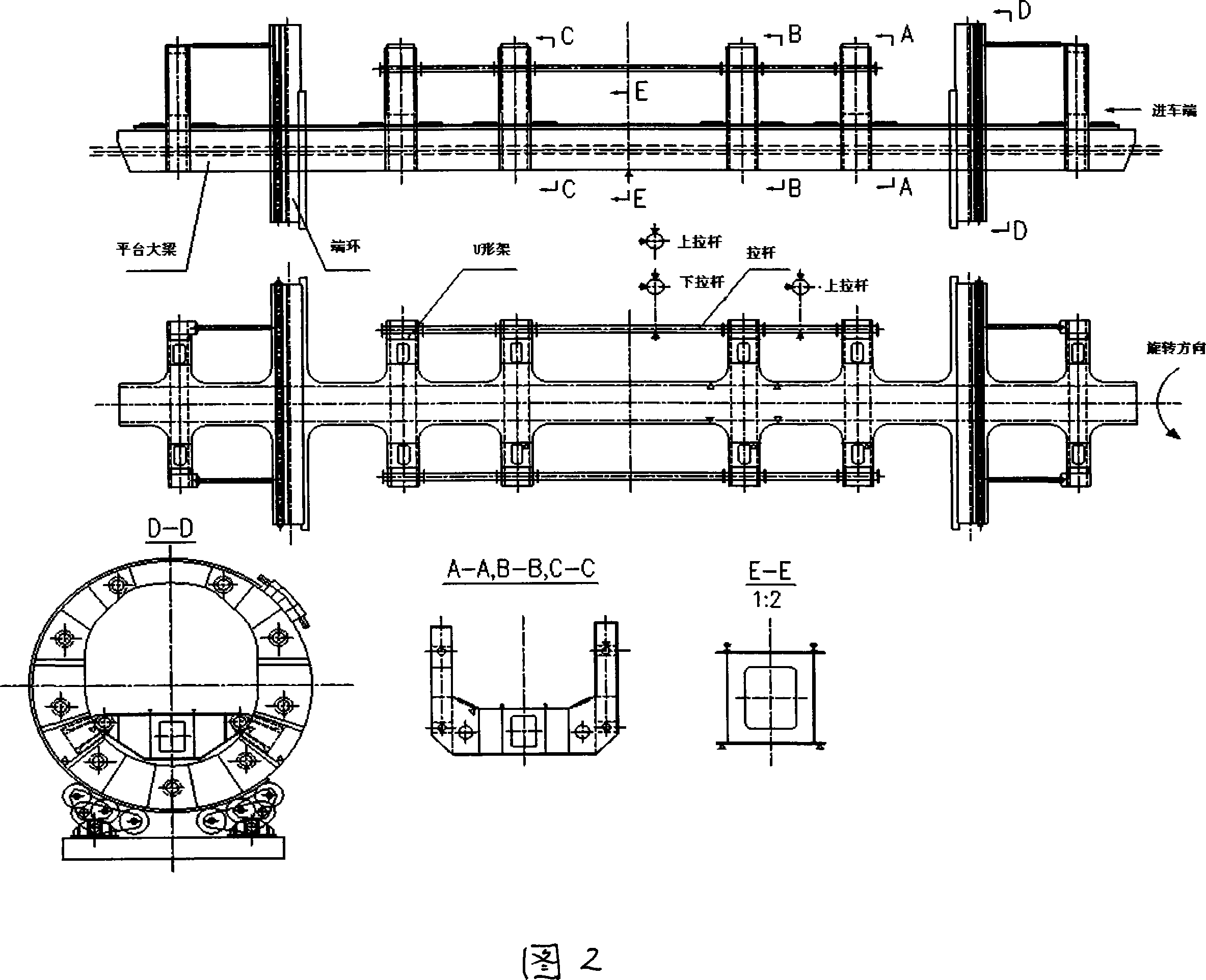

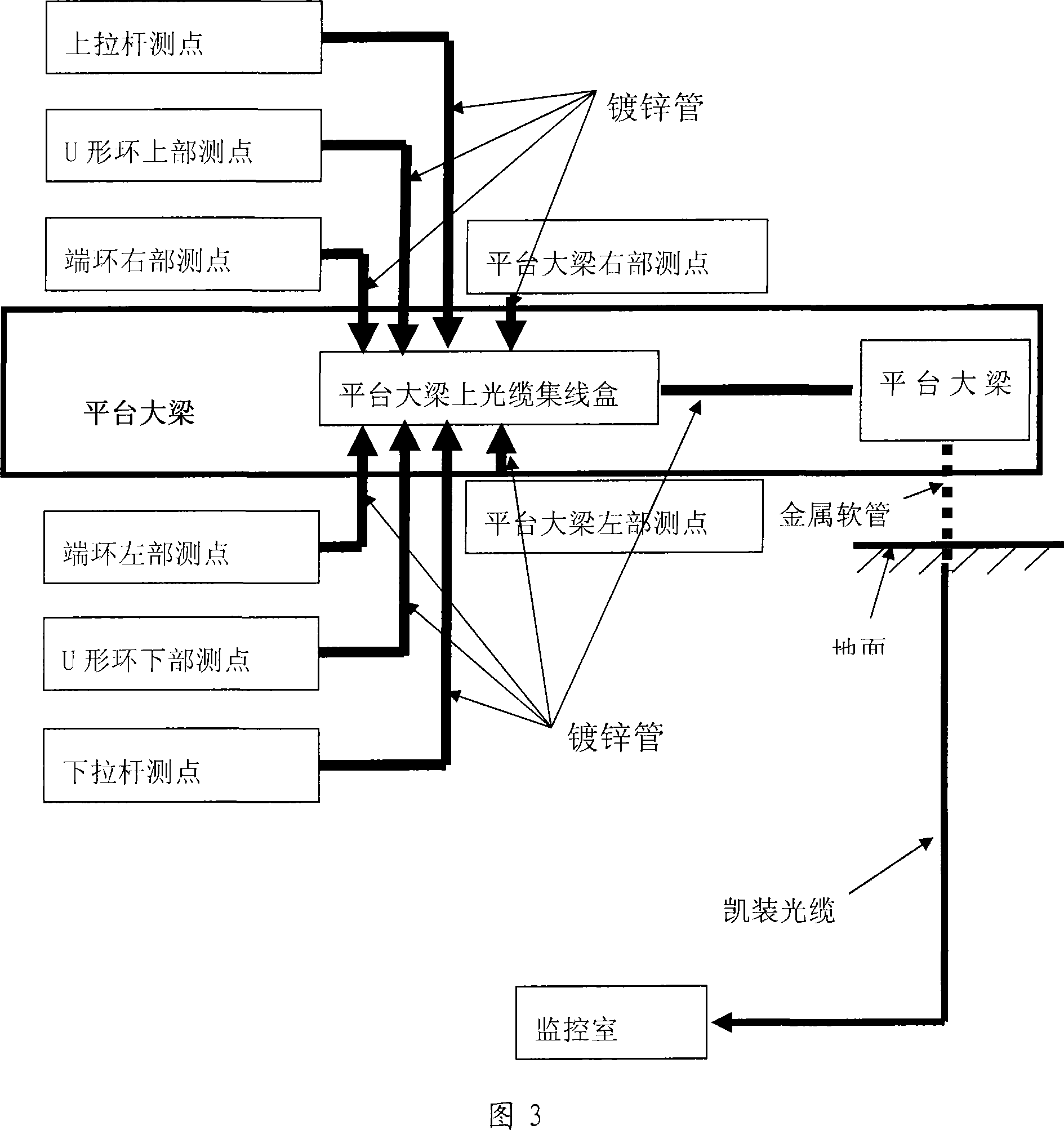

[0036] Step 1: Analyze the structure of the dumper according to the design drawings, establish a model, find the key points, and optimize the layout plan: the dumper consists of an end ring, a U-shaped ring, a front beam, a rear beam, a bottom beam, a press beam, and a car. Composed of plates, tie rods, etc. The structure of the dumper is complex in stress. According to the stress state of each main part, the selected layout scheme (Figure 2) is as follows:

[0037] A total of 44 FBG strain sensors and 4 FBG temperature compensation sensors are arranged. Strain sensors are arranged at 19 measuring points, among which,

[0038] End ring: 4×3 (arrange 4 measuring points, each measuring point has 3 strain sensors to form a strain rosette)

[0039] Platform girder: 4×2 (arrange 4 measuring points: 4 measuring points each with two strain sensors, at right angles);

[0040] At the slope of the lower part of the U-shaped frame: 3×3 (3 measuring points are arranged, and each measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com