Screen filter

A technology of mesh filter and filter screen, applied in the direction of fixed filter element filter, filter separation, chemical instrument and method, etc., can solve the problem of affecting the operation efficiency and function of irrigation system, reducing the service life of filter, and easy clogging of filter And other problems, to achieve the effect of prolonging the working time of filtration, reducing the load, and good flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

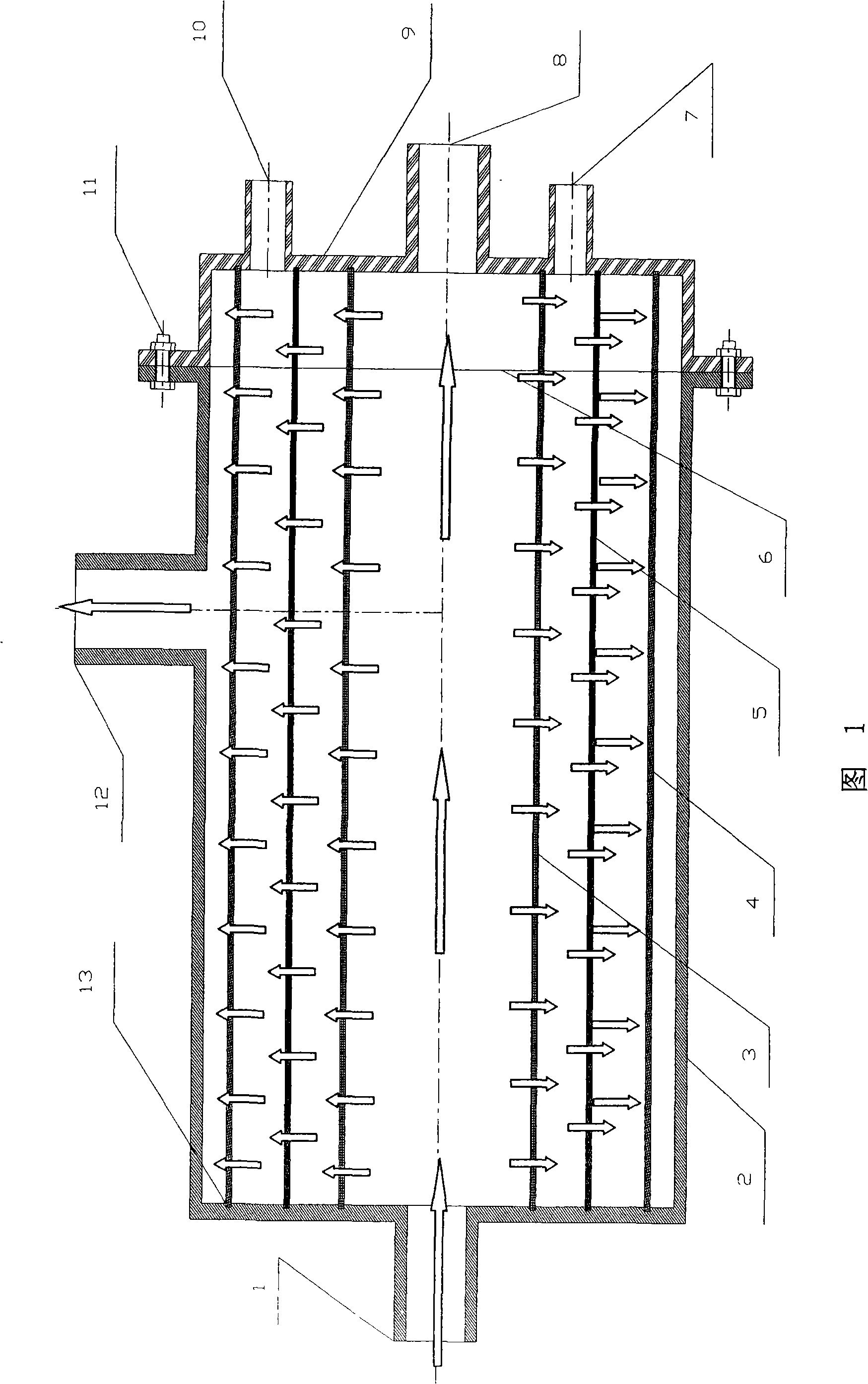

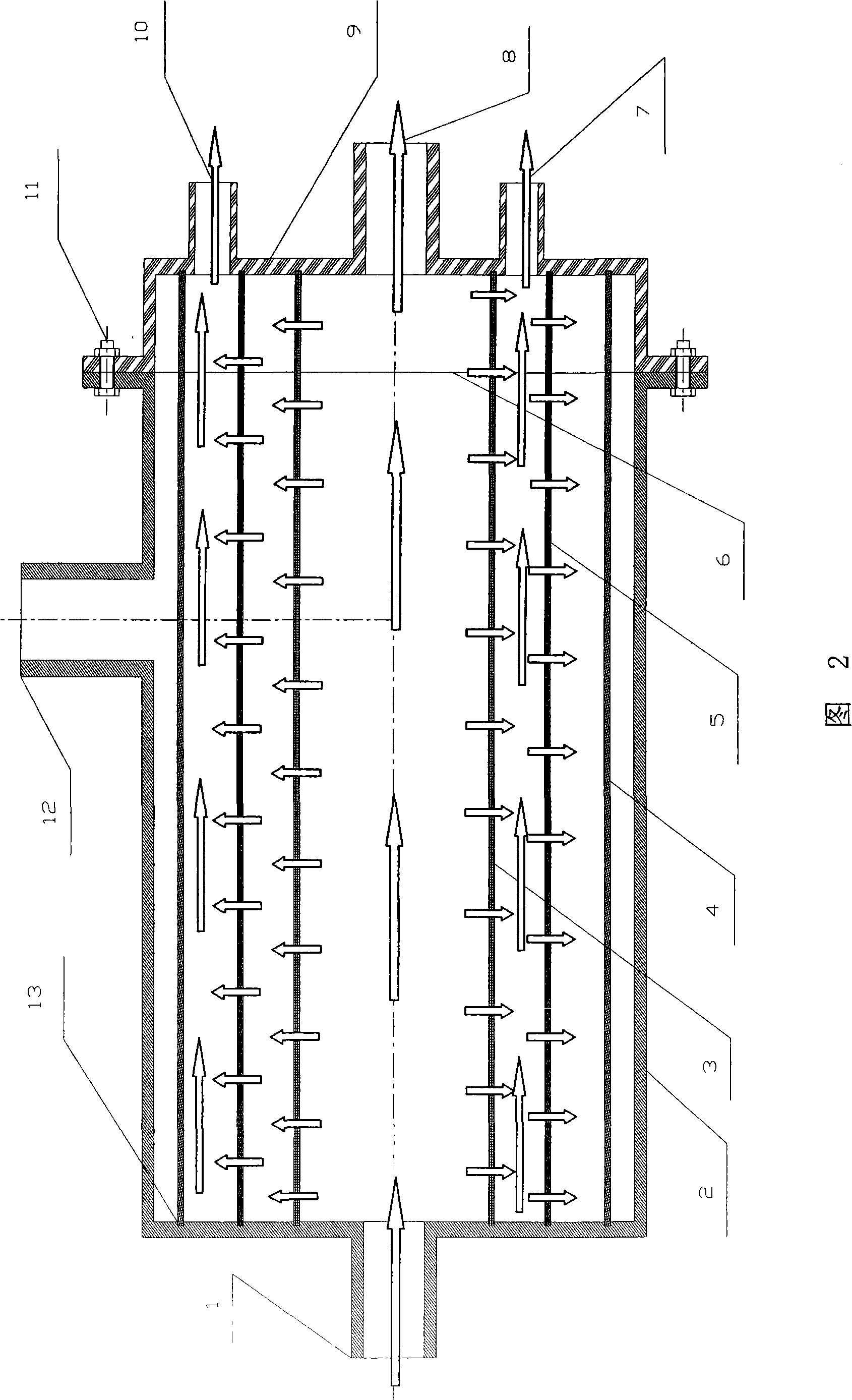

[0018] The filter includes shell, upper cover, water inlet, water outlet, sewage valve, primary screen (coarse filter), secondary screen (medium filter), and third screen (fine filter) (see figure 1, Figure 2).

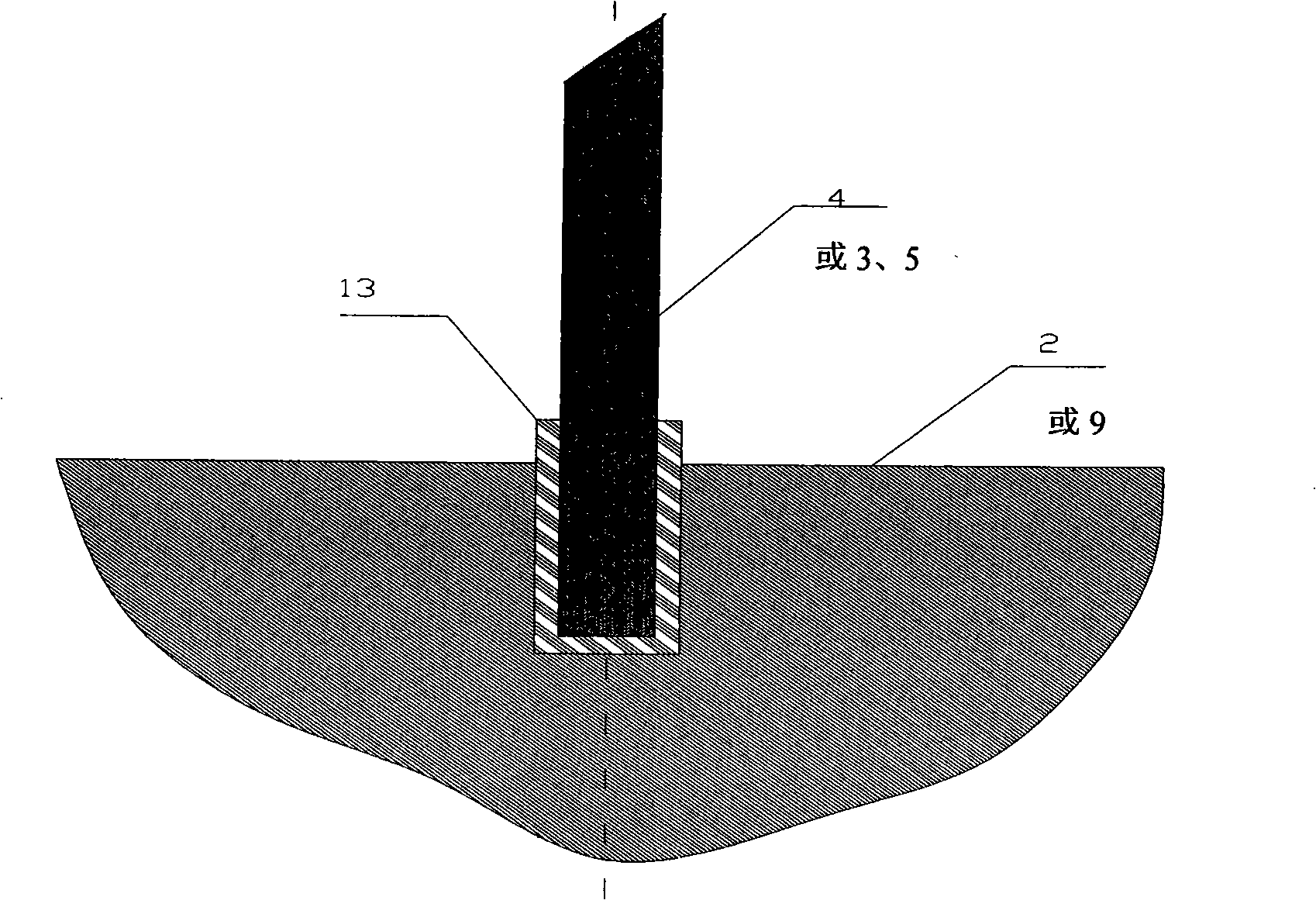

[0019] In Figure 1, 1 is the water inlet of the filter, 2 is the shell of the filter, 3 is the first layer of filter (coarse mesh), 4 is the third layer of filter (fine mesh), 5 is the second layer of filter (middle net), 6 is the sealing gasket between the filter shell and the upper cover, 7 is the sewage outlet of the second layer of filter screen, 8 is the sewage outlet of the first layer of filter screen, 9 is the upper cover of the filter, 10 is The sewage outlet of the third layer filter screen, 11 is a fixed bolt assembly, 12 is a water outlet, and 13 is a sealing washer. In this embodiment, there are three layers of filter sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com