Modified molecular screen base precious metal diesel oil deepness hydrogenation dearomatization catalyst and method of preparing the same

A composite molecular sieve and deep hydrogenation technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, hydrogenation refining of aromatics, etc., can solve the problem of difficult control of active ring opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] (1) Preparation process of ultrafine NaY

[0025] Preparation of NaY guiding agent: in molar ratio: Na2O: Al2O3: SiO2: H2O=18.0:1:18.5:370 Feeding: Weigh 49.588g NaOH and dissolve it in 86.3ml sodium metaaluminate solution, add water glass 27.2g dropwise, supplement 21.27ml of deionized water, stirred for 2 hours, and aged at room temperature for 24-48 hours to obtain a transparent sol.

[0026]Synthesis of ultrafine NaY molecular sieves: Feed the ingredients in a certain molar ratio (Na2O:Al2O3:SiO2:H2O=3.36:1:8.4:250), that is, add 82.254g water glass, 54.894g directing agent, 11.64g ml of deionized water, 37.92 ml of aluminum sulfate solution and 25.22 ml of sodium metaaluminate solution, the amount of directing agent added is 10% (according to Al2O3). Stir vigorously at room temperature for 3 hours, put it into a stainless steel reactor lined with polytetrafluoroethylene, age at 30°C for 9.5 hours, and heat up to 90°C for 11 hours of crystallization. Then take out...

example 2

[0031] The ingredients are fed in a certain molar ratio (Na2O: Al2O3: SiO2: H2O=3.36:1:8.4:250), that is, 82.254g water glass, 54.894g guiding agent, 116.4ml deionized water, 37.92ml Aluminum sulfate solution and 25.22ml sodium metaaluminate solution, the addition amount of directing agent is 10% (according to Al2O3). Stir vigorously at room temperature for 3 hours, put it into a stainless steel reactor lined with polytetrafluoroethylene, age at 14°C for 43 hours, then age at 50°C for 5 hours, and heat up to 100°C for crystallization for 5 hours. Then take out the reactor, and cool it for later use.

[0032] 8.3958g cetyltrimethylammonium bromide is added in the above-mentioned solid-liquid mixture after cooling, adds 53.3013g water glass and aluminum sulfate solution (1.4285gAl (SO ) 3.18H O is dissolved in 30ml deionized water), Then add 100ml deionized water. After stirring for 1 h, concentrated sulfuric acid was added dropwise until the pH value of the mixture was betwee...

example 3

[0034] Grind 87.683g of industrial NaY powder and carry out surface modification, then add it to cetyltrimethylammonium bromide solution (7.5gCTMABr dissolved in 65ml of deionized water), stir for 4h, add dropwise 53.3013g of water glass and Aluminum sulfate solution (1.4285g Al2(SO4)3·18H2O dissolved in 30ml deionized water), after stirring for 1.5h, adjust the pH of the reaction mixture to 10-11 with concentrated sulfuric acid, stir evenly, and put it into a Teflon-lined container Stainless steel reaction kettle, crystallized at 120°C for 24h, then cooled, washed, filtered and dried.

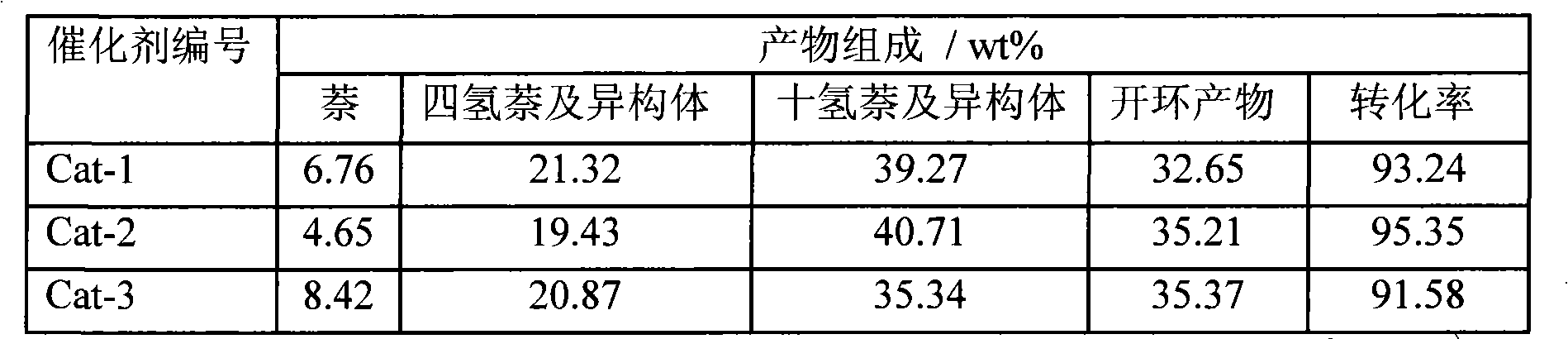

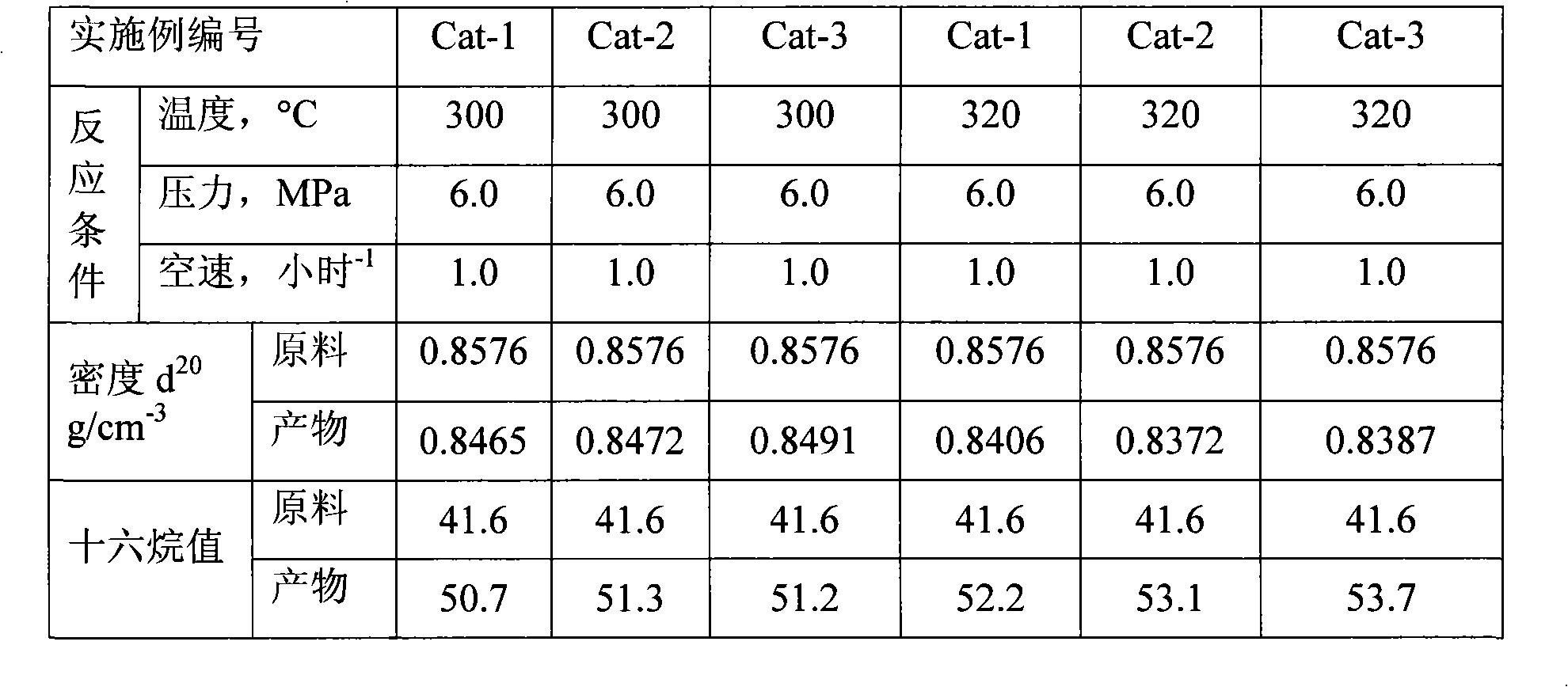

[0035] The composite molecular sieve obtained by the above three methods or the carrier of mechanical mixing adopts the impregnation method to carry metal platinum and palladium with a content of 0.8%, and the ratio of Pt / Pd is 1: 4, 0.6% (in terms of Cr, weight %) Cr2O3. Using the model compound naphthalene and FCC hydro-upgraded diesel as raw materials, the catalyst evaluation test results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap