Method for continuously producing non-corrodible steel and non-corrodible steel composite reel

A stainless steel strip, stainless steel technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of complex process, inability to clad stainless steel, high production cost, and achieve high heat transfer coefficient, high corrosion resistance, high mechanical the effect of strength

Inactive Publication Date: 2008-09-03

孟庆连 +2

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The above-mentioned explosive compounding, explosive hot-rolling compounding, and hot-rolling compounding methods cannot continuously produce coils, and the process is extremely complicated and the production cost is high

The method of semi-continuous periodic production of metal composite strip coils can produce double-sided or single-sided low carbon steel and stainless steel composite strip coils, but cannot composite two different specifications of stainless steel

Method used

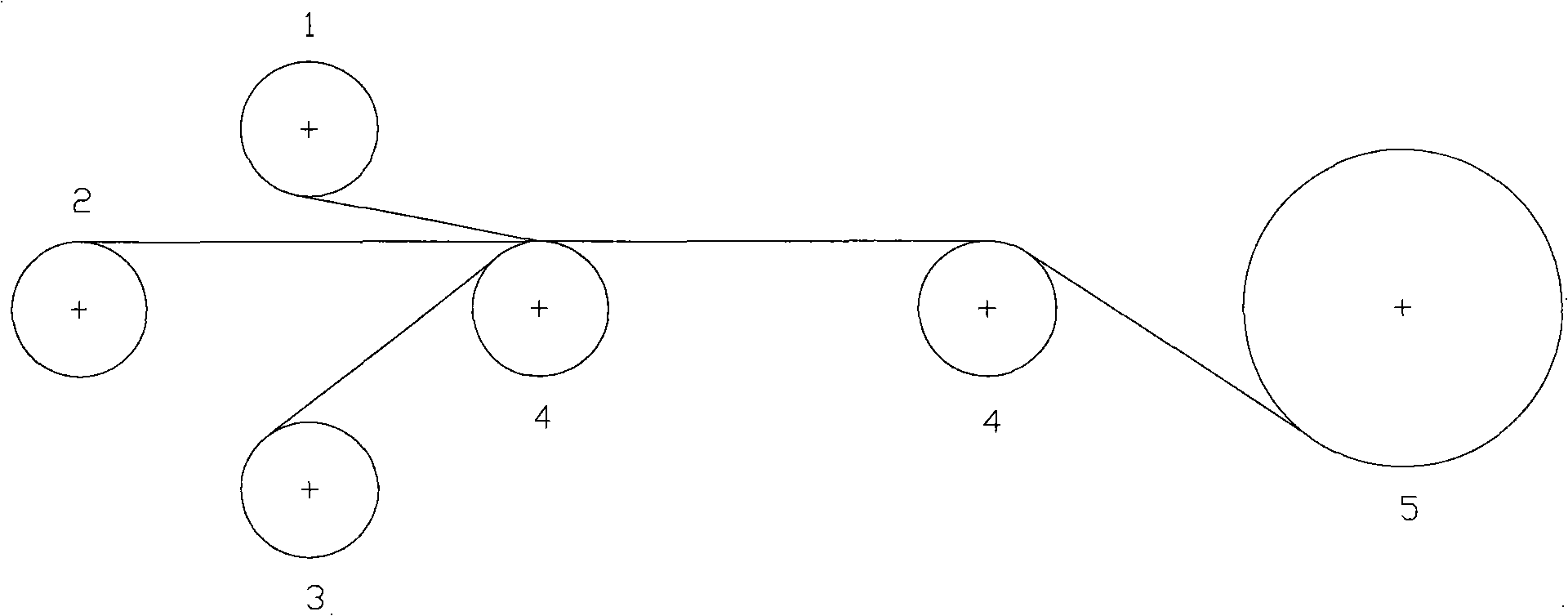

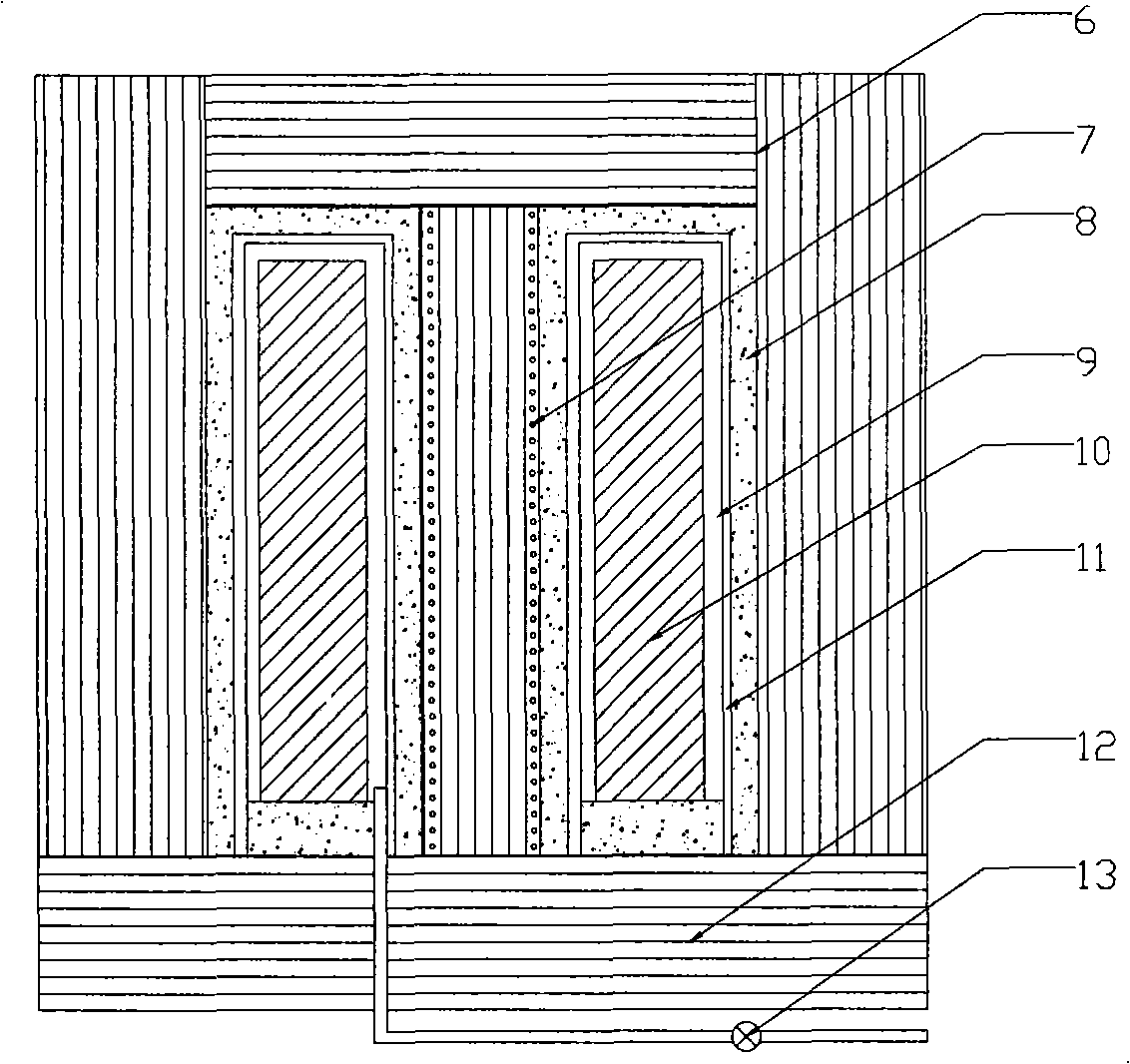

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0024] Adopt the method described in the present invention, manufactured three batches of stainless steel composite coils. See the table for details:

[0025] batch number

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Login to View More

Abstract

A method for continuously producing a stainless steel and stainless steel composite coil, which belongs to the field of stainless steel composite board technology. The method comprises the following steps: continuously sandwiching a solder layer between two kinds of stainless steel, coiling coils of two different materials by a tension of 3 to 30 tons, applying a special high-temperature anti-bonding agent on a roller with non-composite surface, transferring the reeled pre-combined coil to a power induction furnace, heating to 950 to 1,130 DEG C, keeping the temperature, quenching, and tanking out to obtain desired stainless steel composite coil with a combination rate above 99.5% and a shear strength larger than 300 MPa. The method has the advantages that two kinds of stainless steel coils with different trademarks and different thickness can be combined together to obtain a composite stainless steel coil with high corrosion resistance on one side and high mechanical strength and high heat transfer coefficient on the other side.

Description

technical field [0001] The invention belongs to the technical field of stainless steel clad plates, and in particular provides a method for continuously producing stainless steel and stainless steel clad coils, which is suitable for manufacturing various stainless steel and stainless steel clad coils, especially for the production of two different grades of stainless steel for compounding. Methods. Background technique [0002] There are four main manufacturing methods of existing metal clad plates: explosive cladding, explosive hot-rolling cladding, hot-rolling cladding, and semi-continuous periodic production of metal clad coils. [0003] The above-mentioned explosive cladding, explosive hot-rolling cladding, and hot-rolling cladding methods cannot continuously produce coils, and the process is extremely complicated and the production cost is high. The method of semi-continuous periodic production of metal composite strip coils can produce double-sided or single-sided low...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P17/00B23K1/008B23K1/20

Inventor 孟庆连

Owner 孟庆连

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com