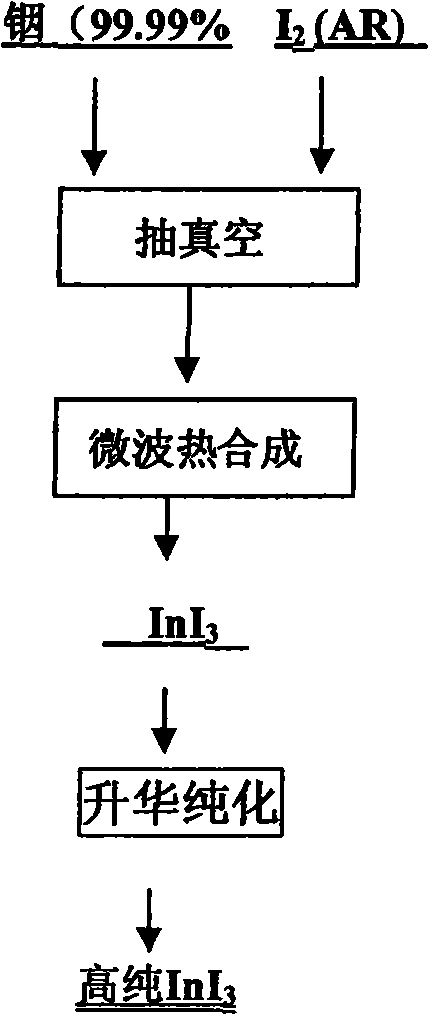

Preparation method of high-purity indium triiodide

A high-purity indium triiodide technology, applied in the field of preparation of high-purity indium triiodide, to achieve high thermal efficiency, selectivity, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

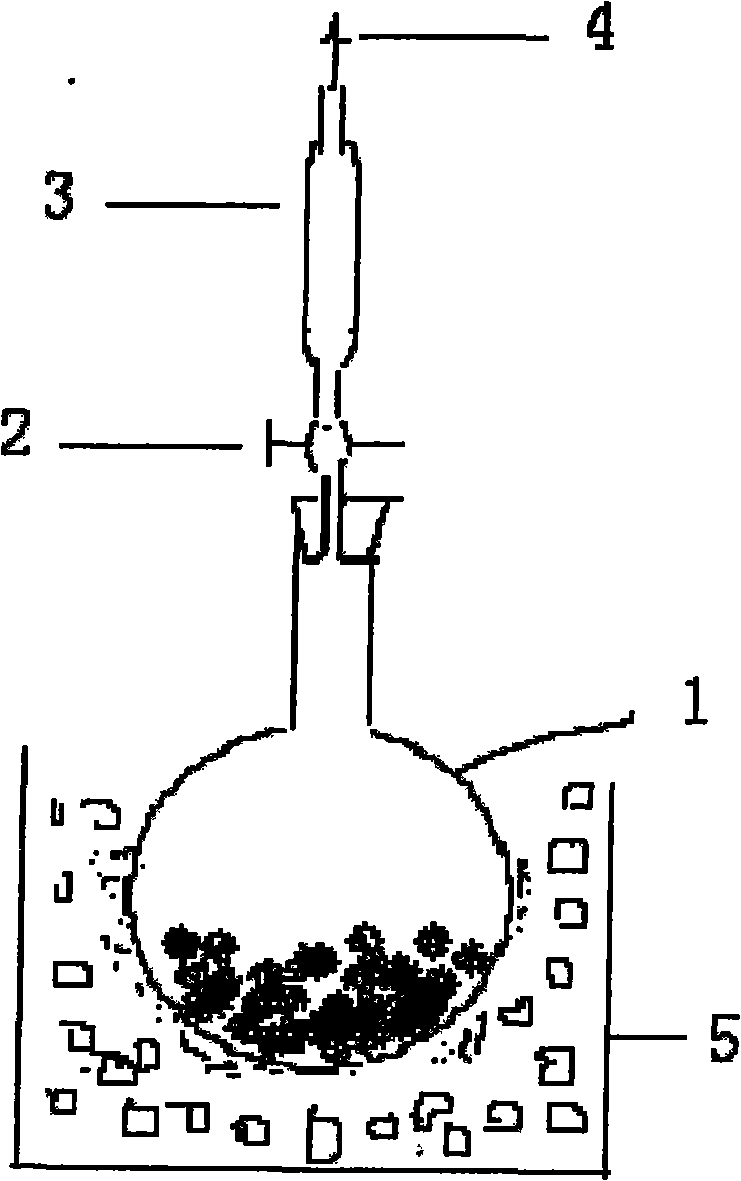

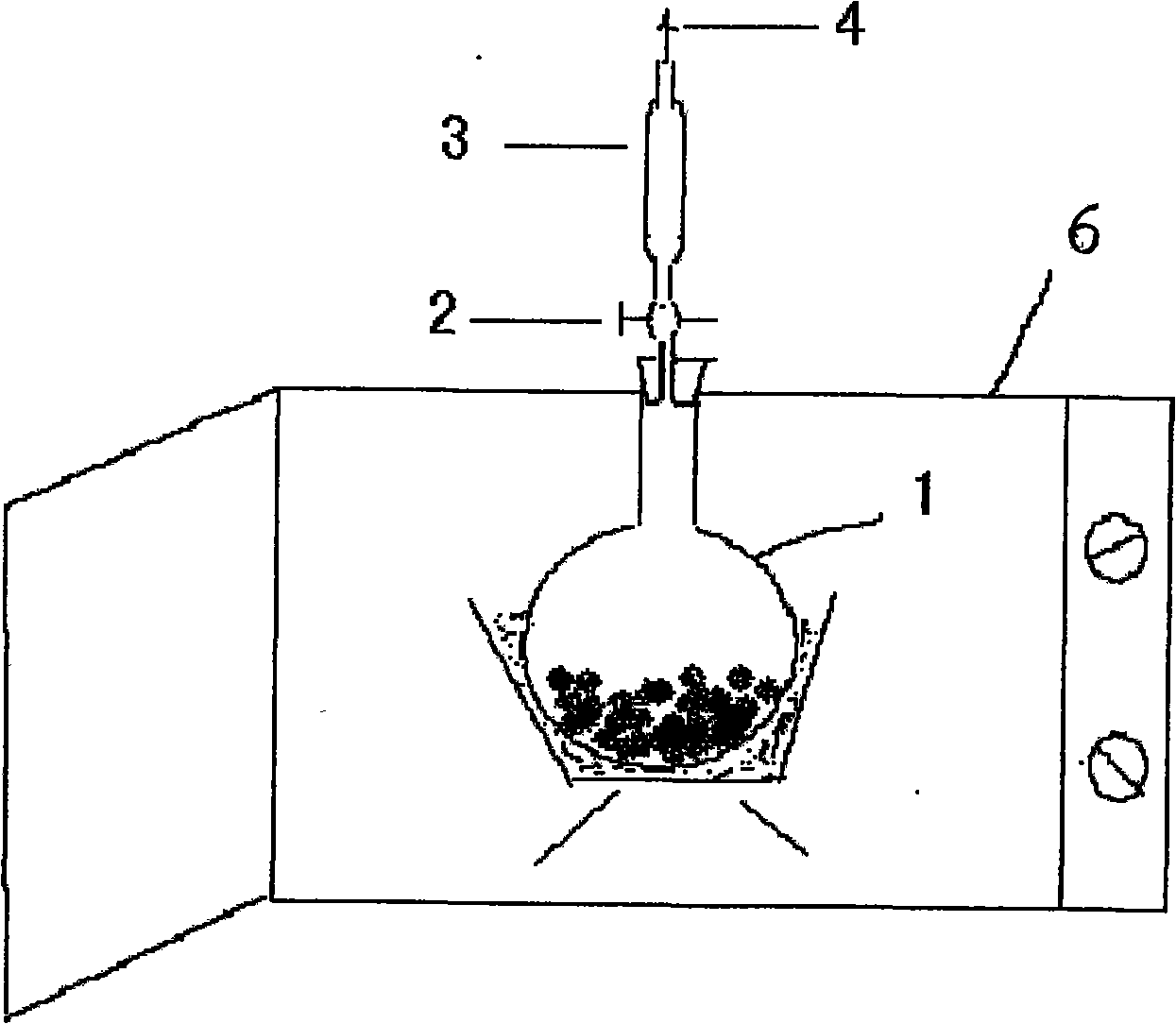

Embodiment 1

[0011] Example 1: Take 1g of 99.99% pure metal indium and 3.316g of analytically pure iodine and mix them, put them into a quartz glass flask washed and dried by aqua regia and deionized water, and seal the quartz glass flask with a rubber stopper and vacuum glue Close the stopcock of the condensate collection tube and connect it to the vacuum pump. Insert the quartz glass flask into a 1:1 ice-salt insulation container, then open the stopcock of the condensate collection tube and vacuumize to 80kPa, then close the stopcock. Then send the vacuumed quartz glass flask device into the prepared microwave oven to start heating. The temperature in the preheating period is controlled at 20-90°C, and the time is 2 minutes; the temperature in the synthesis period is controlled at 90-200°C, and the time is 8 minutes; sublimation During the purification period, the temperature is controlled at 200-250°C for 10 minutes. When the temperature reaches 250°C, open the stopcock to sublimate the...

Embodiment 2

[0012] Embodiment 2: take 99.99% pure metal indium 5g and mix with 18.24g analytical pure iodine (10% iodine excess), the operation process after mixing is exactly the same with embodiment 1, the quartz glass flask device that will pump vacuum is sent into Start heating in the microwave oven. The temperature in the preheating period is controlled at 20-90°C for 5 minutes; the temperature in the synthesis period is controlled at 90-200°C for 9 minutes; the temperature in the sublimation purification period is controlled at 200-250°C for 15 minutes. When the synthesis temperature reaches 250°C, open the stopcock to sublimate the purified yellow InI 3 Condensate in the condensate collection tube. The purity of the product is greater than 99.99%, and its yield is 98%.

Embodiment 3

[0013] Embodiment 3: take by weighing 99.99% pure metal indium 10g and 39.79g analysis pure iodine (20% of iodine excess) mix, the operation process after mixing is exactly the same with embodiment 1, the quartz glass flask device that will pump vacuum is sent into Start heating in the microwave oven, strictly control the temperature within the range of 20-250°C, and complete the entire test within 25 minutes. At this time, the temperature in the preheating period is controlled at 20-90°C for 2 minutes; the temperature in the synthesis period is controlled at 90-200°C for 14 minutes; the temperature in the sublimation purification period is controlled at 200-250°C for 10 minutes. When the synthesis temperature reaches 250°C, open the stopcock to sublimate the purified yellow InI 3 Condensate in the condensate collection tube. The product has a purity of 99.999% and a yield of 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com