Thermoplastic resin composition

A technology of resin composition and thermoplastic resin, which is applied in the field of thermoplastic resin composition and can solve the problems of poor impact resistance at low temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

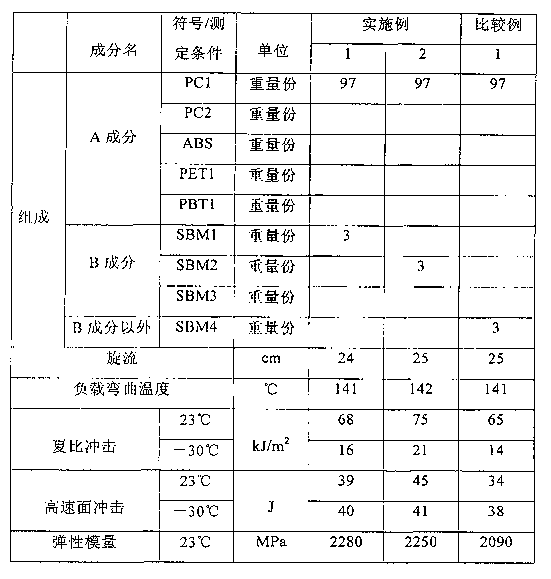

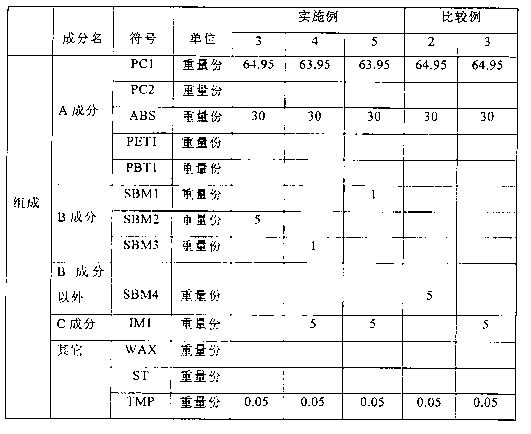

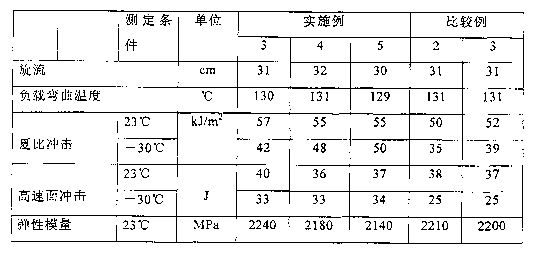

Examples

Embodiment

[0148] (1) Raw materials of the resin composition

[0149] (A-1 component)

[0150] PC-1: linear aromatic polycarbonate resin powder with a viscosity-average molecular weight of 22400 produced from bisphenol A and phosgene (Panlite L-1225WP (trade name), manufactured by Teijin Chemicals Co., Ltd.)

[0151] PC-2: Linear aromatic polycarbonate resin powder with a viscosity-average molecular weight of 19,700 produced from bisphenol A and phosgene (Panlite L-1225WX (trade name), manufactured by Teijin Chemicals Co., Ltd.)

[0152] (A-2 component)

[0153] ABS: ABS resin pellets (Santaku UT-61 (trade name), manufactured by NIPPON A&L INC.)

[0154] (A-3 ingredient)

[0155] PET1: Polyethylene terephthalate resin (TR-MB (trade name), manufactured by Teijin Chemicals Co., Ltd.) with an IV value of 0.51 and an amount of terminal carboxyl groups of 26.3 eq / ton when polymerized using a germanium compound polymerization catalyst

[0156] PBT1: polybutylene terephthalate having an IV ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com