Steady ultra-hydrophobic surface controllable design method based on geometric analysis

A technology of super-hydrophobic surface and geometric analysis, applied in the field of controllable design of stable super-hydrophobic surface, can solve problems such as the calculation method of critical height without in-depth study, and achieve the effect of wide practicability, strong controllability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

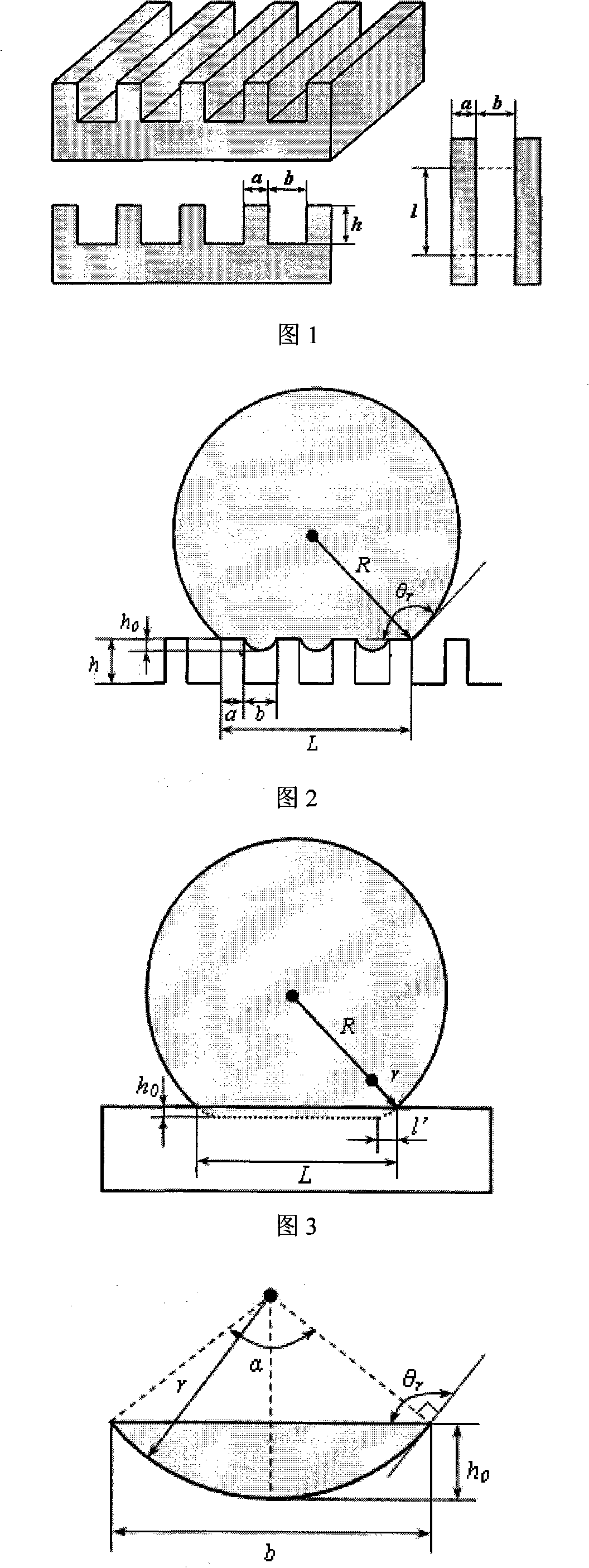

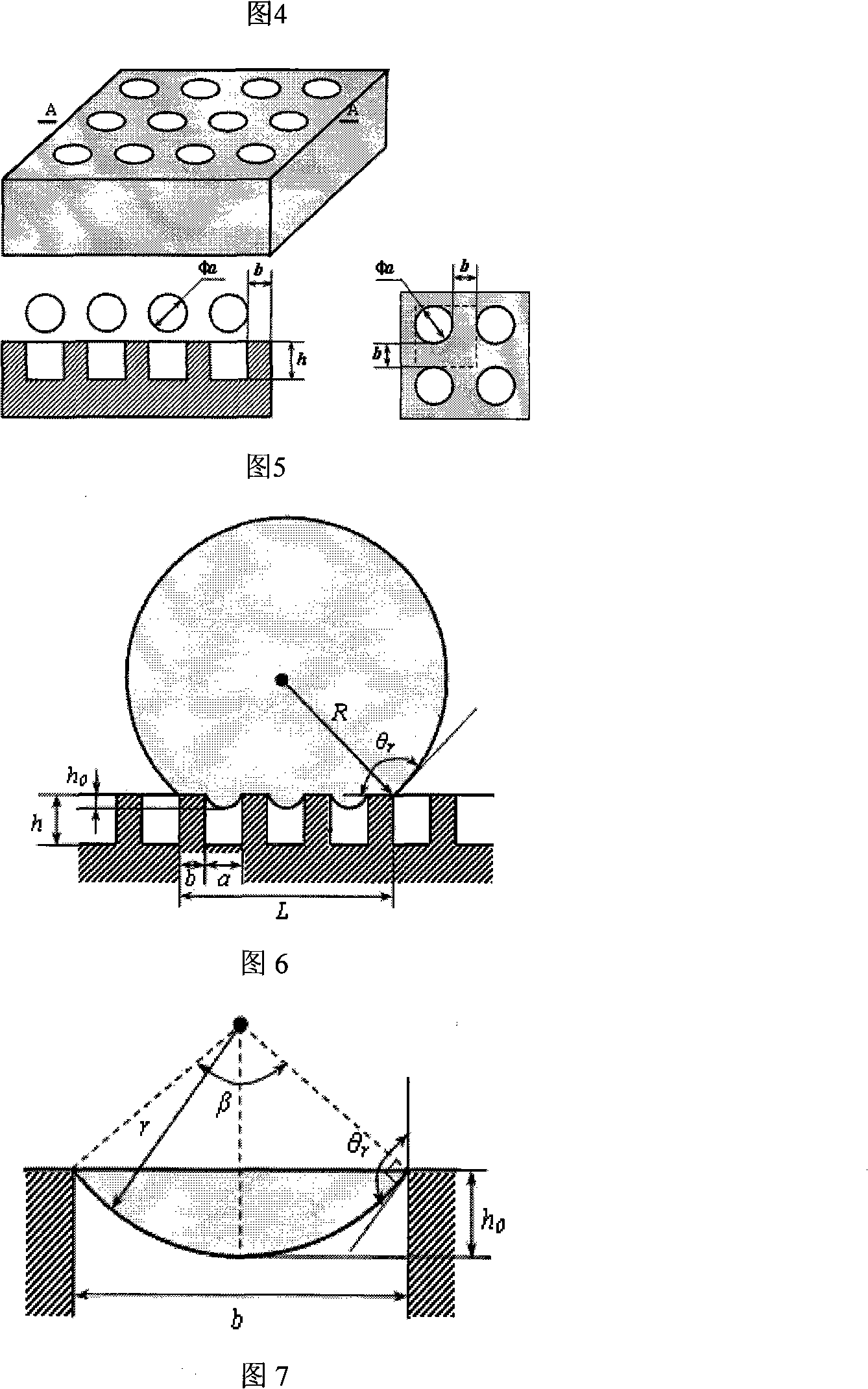

[0025] The details of the technical solutions proposed by the present invention will be described below by taking parallel grating-shaped microstructured surfaces and circular pit-shaped microstructured surfaces as examples.

[0026] (1) Parallel grating microstructure surface

[0027] Theoretical prediction formula of apparent contact angle is deduced first. Figure 1 is a schematic diagram of a parallel grating-shaped microstructure model and its parameter design. The geometric parameters involved include grating width a, spacing (ie, groove width) b, and groove depth h. Select the area inside the dotted line box on the right of the figure as a period for analysis, choose the length of the grating direction as l, according to r and f 1 The definition of is: r=[(a+b) l+2h l] / [(a+b) l]=1+2h / (a+b), f 1 =(a·l) / [(a+b)·l]=a / (a+b). Substitute into formula (1) and formula (2) respectively to get:

[0028] cos θ r W ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com