Digital-control and general lathe

A technology of lathes and turning tools, applied in the field of digital compatible lathes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with the preferred embodiment shown in accompanying drawing, do further detailed description:

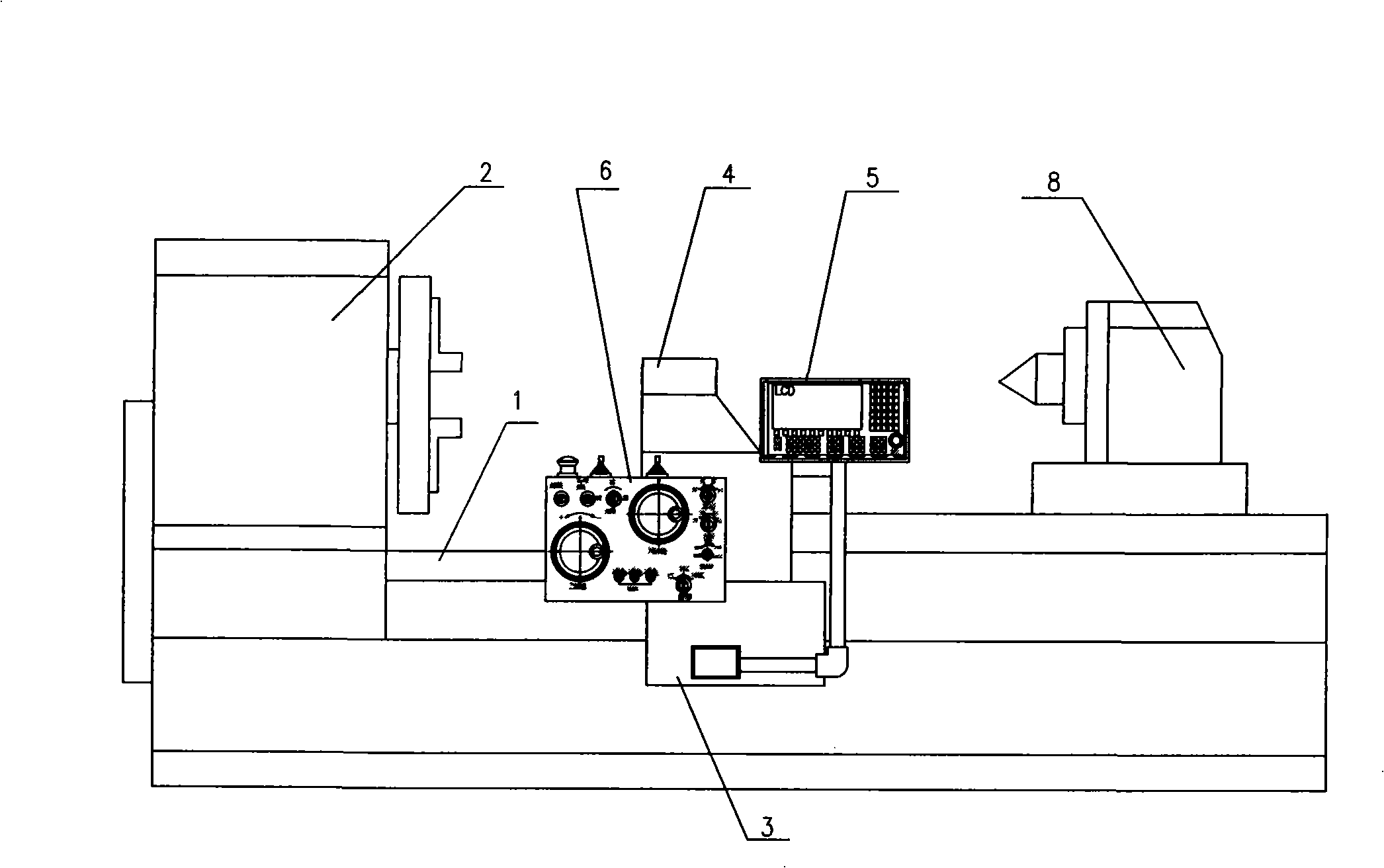

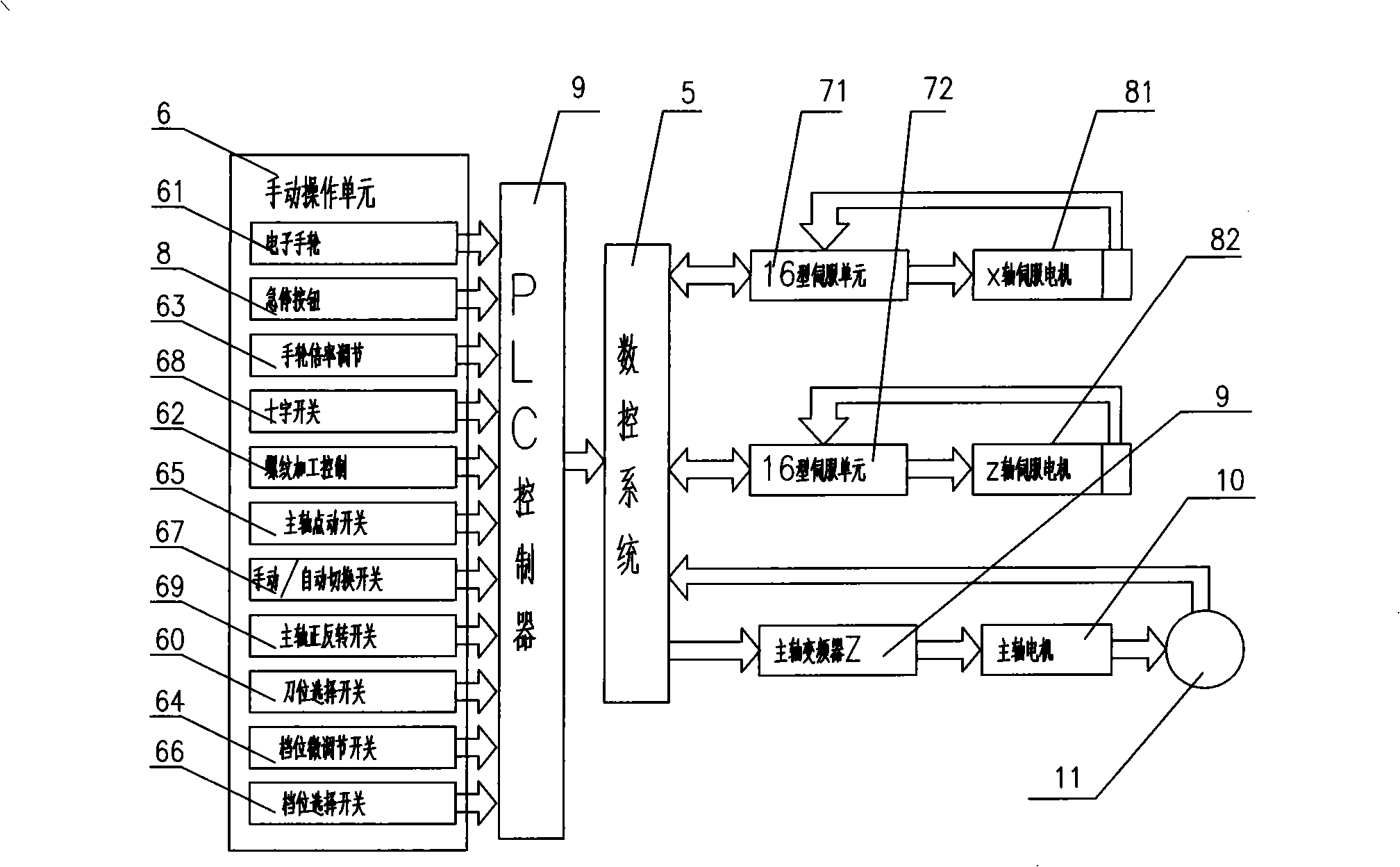

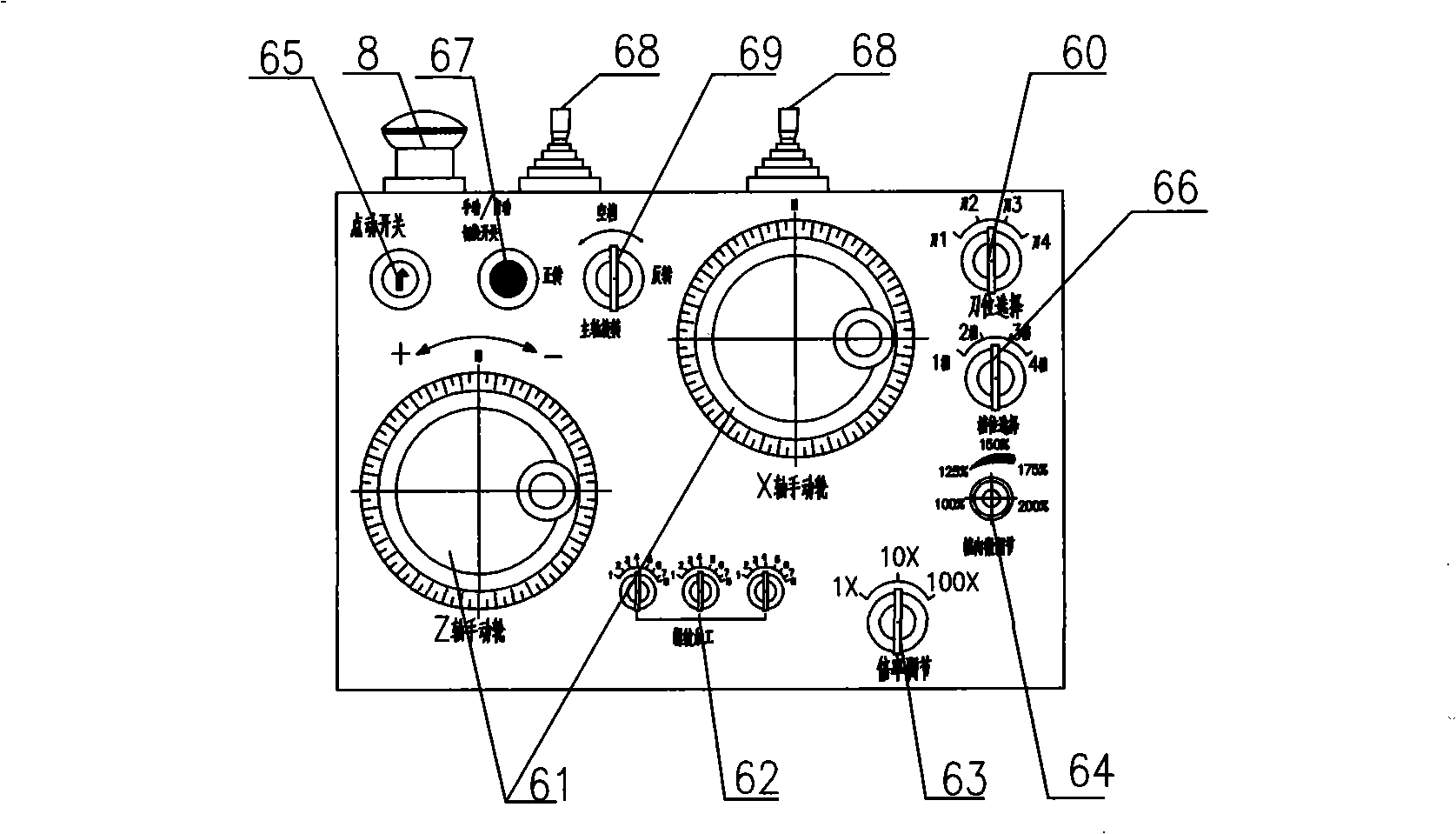

[0052] See figure 1 , 2 , 3, the spindle box 2, the slide box 3 and the tailstock 8 of the said number-general compatible lathe are arranged on the bed 1, and the tool rest 4 and the numerical control system 5 are arranged on the slide box 3, which is characterized in that it also includes There is a manual operation unit 6 on the sliding crate 3, and the manual operation unit 6 is provided with a knife position selection switch 60, a handwheel input device 61, and a thread processing control switch connected to the numerical control system 5 through the PLC controller 9. 62. Handwheel magnification adjustment switch 63, gear micro-adjustment switch 64, spindle inching switch 65, gear selection switch 66, manual / automatic switching switch 67, cross switch 68, spindle forward and reverse control switch 69 and emergency stop button 8.

[0053] Described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com