Micro- suspension stain technology

A kind of micro-suspension and technology, applied in the field of dyeing and finishing, can solve the problems of difficulty in dyeing soybean protein fibers, and achieve the effects of bright color, improved dyeing rate and soft hand feeling.

Inactive Publication Date: 2008-09-10

JIANGSU HUAJIA SILK

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The task of the present invention is to provide a microsuspension dyeing technology to solve the difficult problem of soybean protein fiber dyeing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

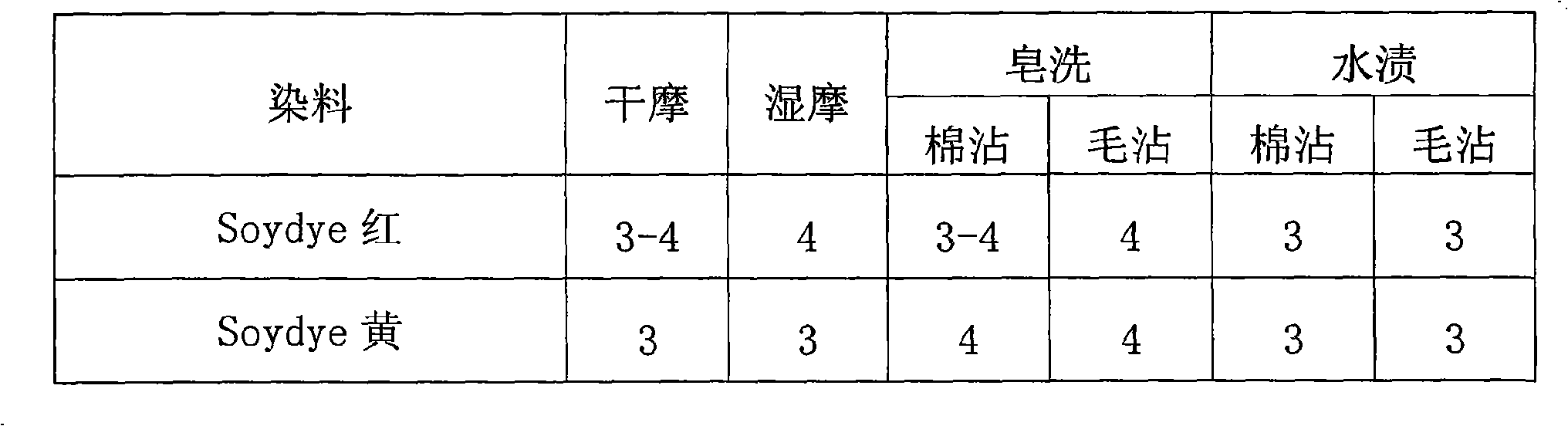

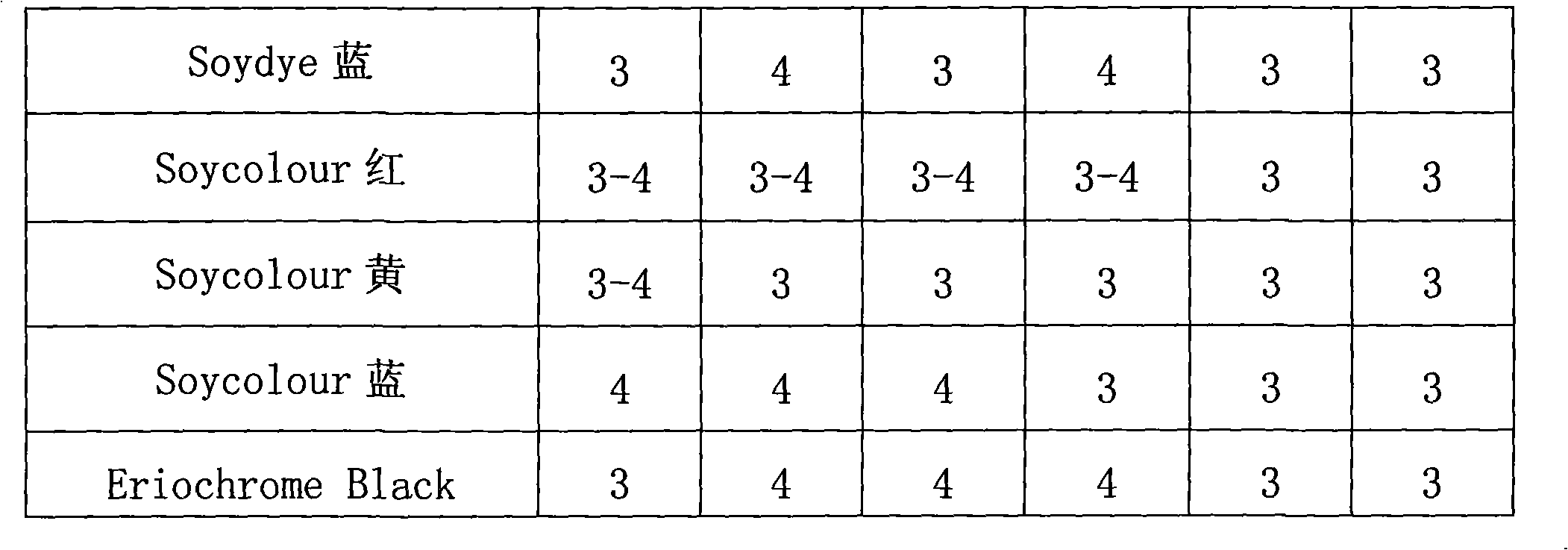

[0007] Example 1: Zhejiang Jiaxing Huameng Wool Textile Co., Ltd. conducts specific tests on the color fastness of all dyes processed in actual production according to national standards. The tested dyes are all dark product samples, and the amount of dye is 5 -6%, the test data is as follows:

[0008] Soy protein fiber dark product color fastness test results (grade)

[0009]

[0010]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a micro-soliquid dyeing technique, which solves the problem that the soybean fiber is difficult to dye. The dyeing technique is characterized in that the dyeing formula is that 0.01 to 0.6 percent of Soydye, 0.2 to 0.5 percent of Soyprom I dye, 1.5 percent of formic acid and 1.2 percent of Soyprom II dye; at the temperature of 30 DEG C, the four dye formulas are added into a dye bath with a pH value of 4 in sequence, stable dye micro-soliquids are formed rapidly in the dye bath and are dyed by certain dyeing method, afterwards, the conventional dye post treatment is adopted to process and the whole dye process is finished. The micro-soliquid dyeing technique improves the dye uptake, the fixation ratio and the color fastness of the soybean fiber; moreover, the dyed product has bright color and soft tactility and accords with the 'clean production'.

Description

Technical field [0001] The invention belongs to the field of dyeing and finishing, in particular to a micro-suspension dyeing technology. Background technique [0002] At present, the use of existing dyes and corresponding traditional dyeing processes to dye soy protein fibers will have the problems of low dye uptake and poor dye fastness. The main reason for the decrease in the dyeing percentage of soy protein fibers by dyes is that the surface of the dye fibers has poor adsorption capacity for dye molecules, which causes a large amount of dyes to stay in the dye bath. The main reason for the poor color fastness is also that the fiber macromolecule itself cannot form an effective combination with the dye. When dyeing with conventional wool dyes, the above two problems are very prominent. Even if the traditional reactive dyes are used for dyeing, since the hydroxyl group on the side chain of the polyvinyl alcohol macromolecule is a secondary hydroxyl group, its reflection activit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06P5/00D06P3/04

Inventor 王永根

Owner JIANGSU HUAJIA SILK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com