Bearing force-free anti-knock steel support system

A technology of support system and seismic steel, applied in earthquake resistance, building components, building structure, etc., can solve the problems of prolonged construction period, prolonged construction period, inconvenience, etc., and achieve the effect of delaying degradation, improving seismic performance and slowing down degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

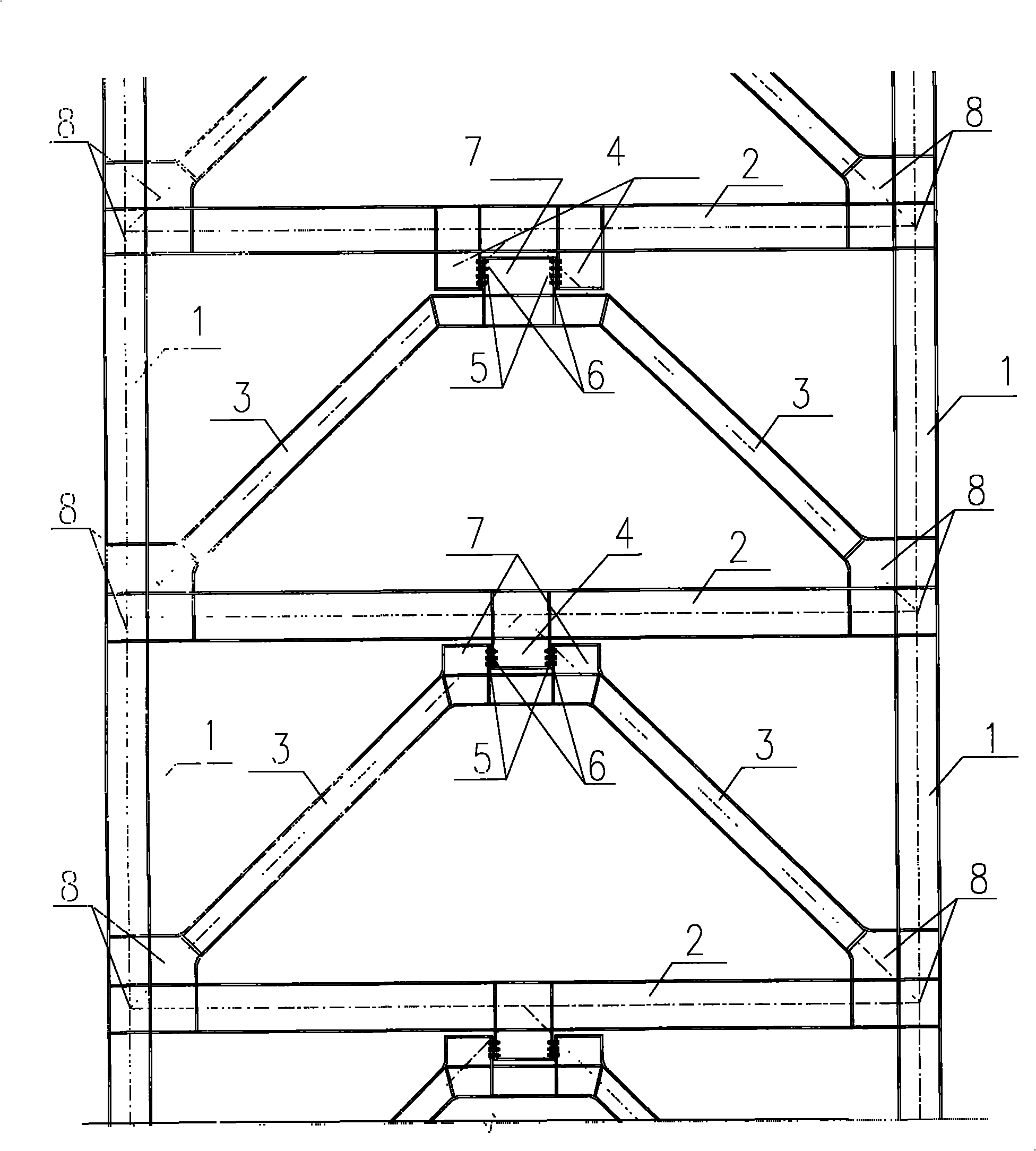

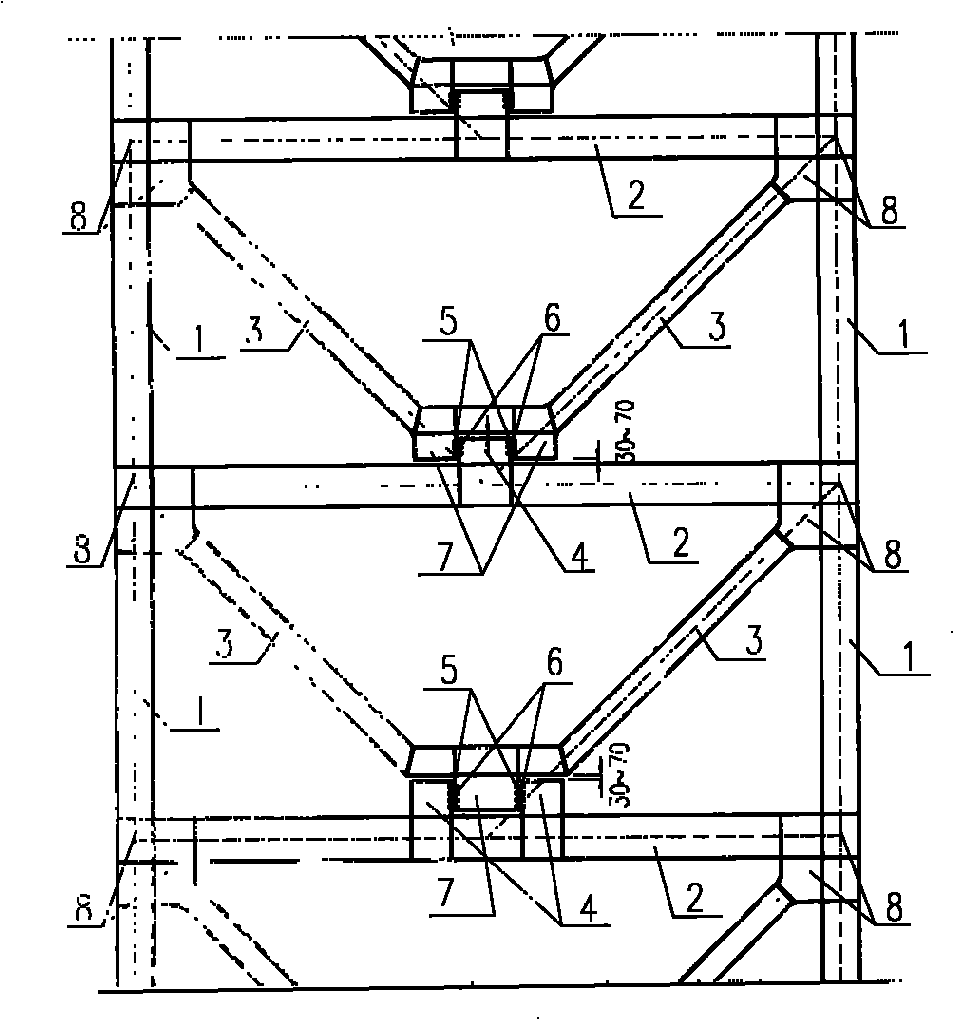

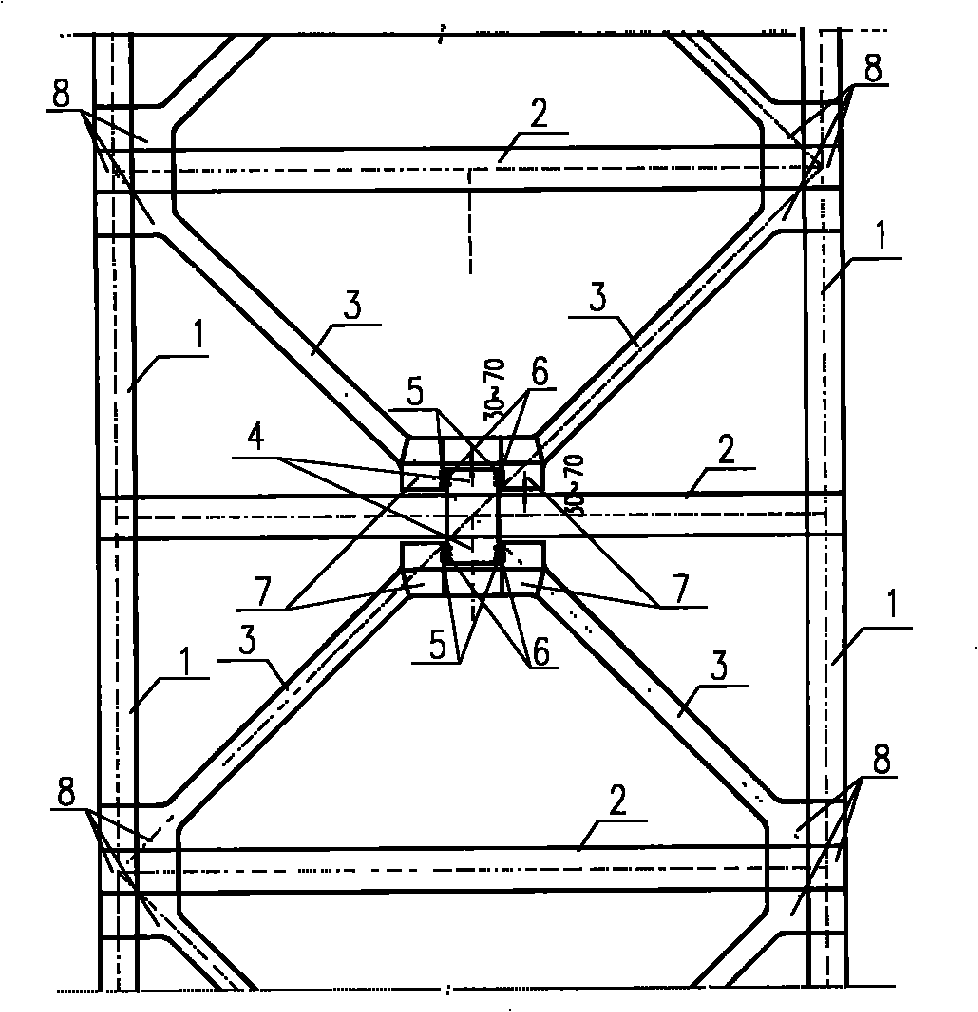

[0023] The gravity-free anti-seismic steel support system is composed of multiple splayed oblique support units, which include steel columns 1, steel beams 2, steel oblique supports 3, steel beam corbels 4, bolts 5, and thin steel pads Sheet 6, support corbel 7, support node 8, the bottom of the two steel diagonal supports 3 is connected with the intersection of the lower ends of the two steel columns 1 and the steel beam 2 via the support node 8, and the upper ends of the two steel diagonal supports 3 are provided with a support corbel 7 , the supporting corbel 7 is connected with the side of the steel beam corbel 4 fixed on the steel beam 2 through the bolt 5, the two ends of the steel beam 2 are connected with the upper end of the steel column 1 through the support node 8, the supporting corbel 7 is connected with the steel beam corbel A steel shim 6 is provided between the legs 4 . The thin steel gasket 6 has a thickness of 1-5 mm.

[0024] The bolt connection holes of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com