High-temperature metal organic chemical gas-phase deposition reactor

A metal-organic chemistry and vapor deposition technology, which is applied in the field of reactors, can solve problems affecting the growth mechanism of thin films and difficult to control, and achieve the effects of improving quality and uniformity, reducing pre-reaction, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

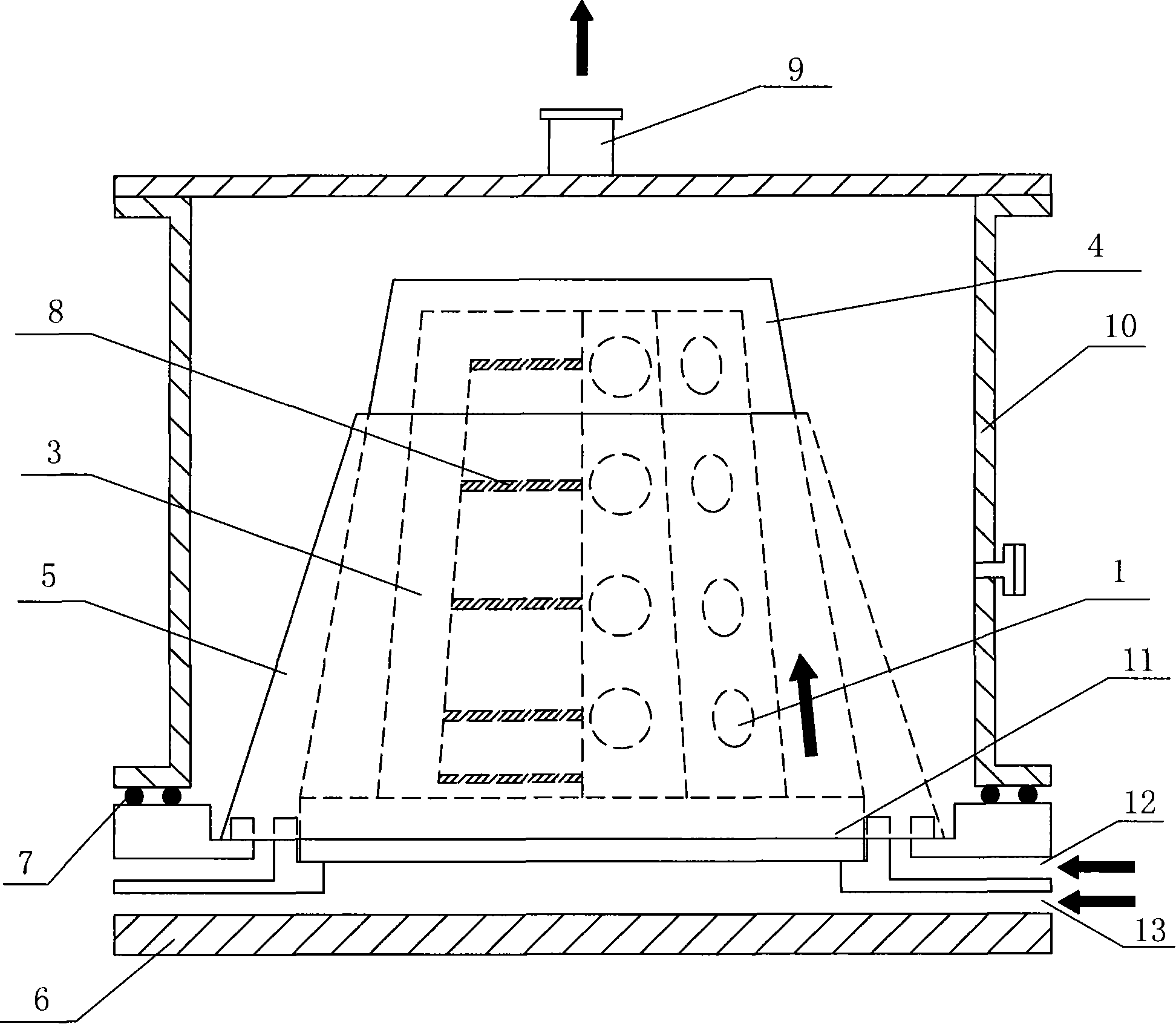

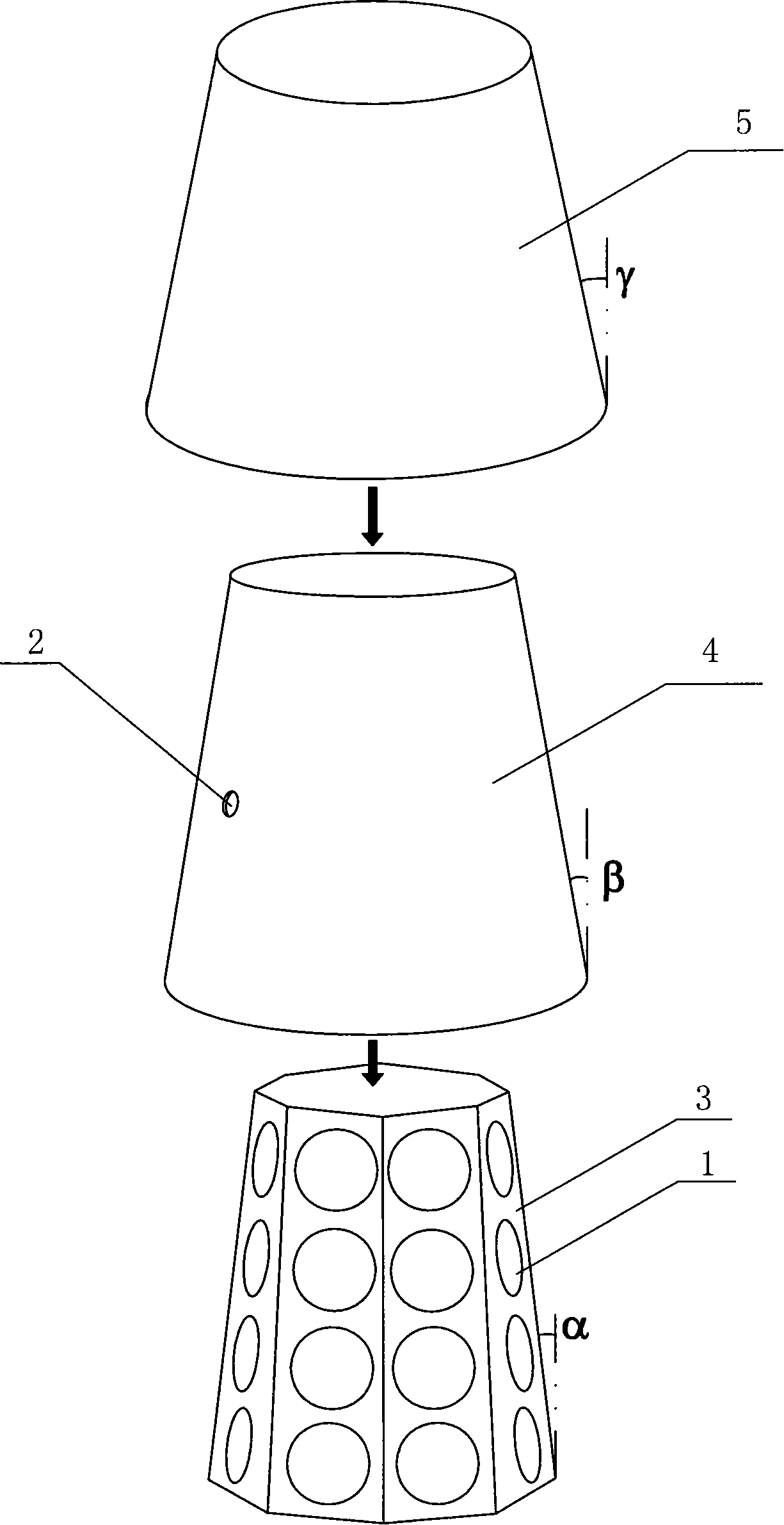

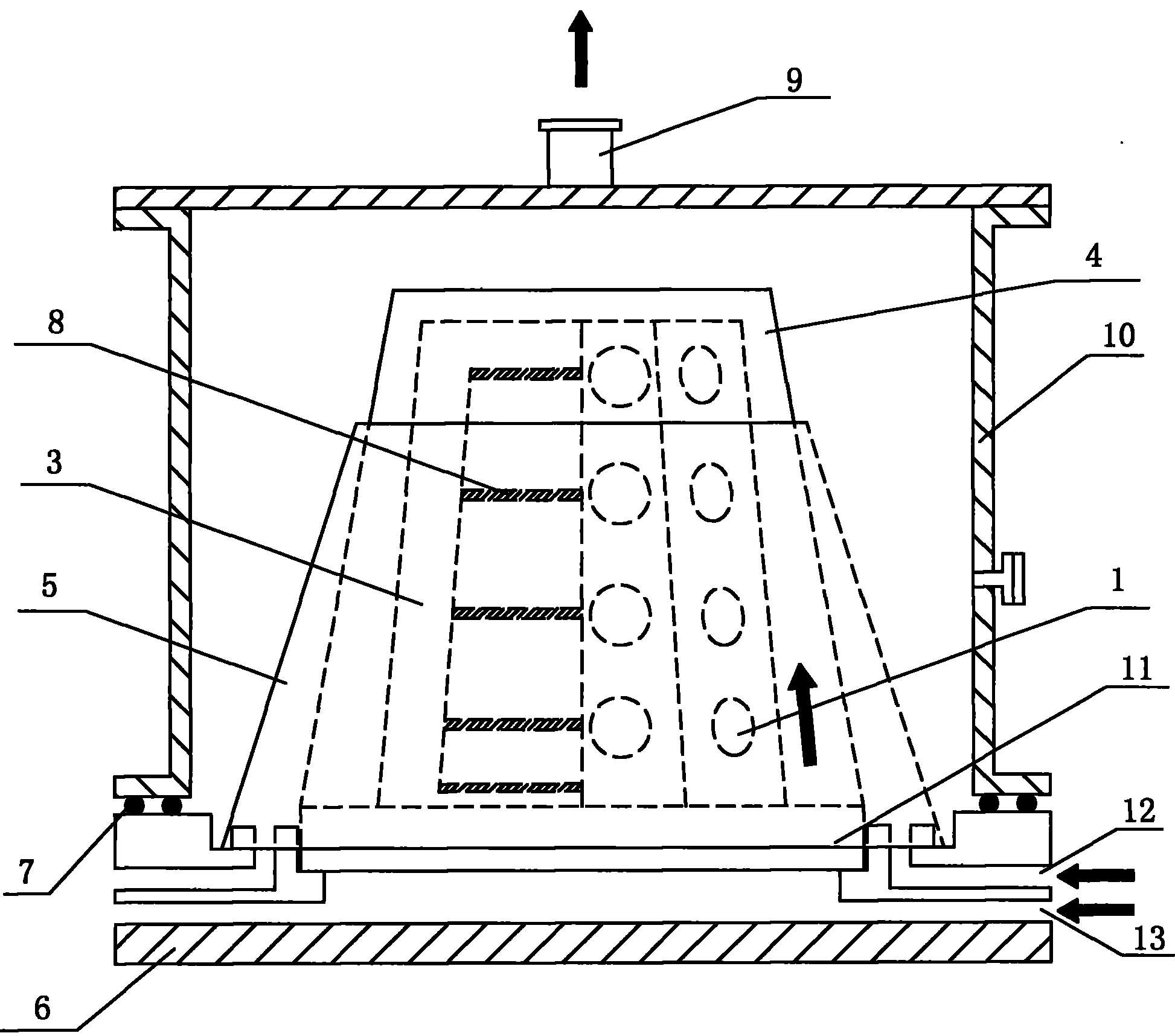

[0023] Embodiment one: see figure 1 , 2 As shown, a high-temperature metal-organic chemical vapor deposition reactor includes a shell, a reaction chamber, a sample delivery chamber, a vacuum device, an exhaust gas treatment device, and an operation control device. The substrate for the deposition reaction and the heating assembly for heating the substrate are placed in the reaction chamber. The reaction chamber is a cone barrel-shaped structure with an upper bottom surface smaller than the lower bottom surface, including an octagonal cone-shaped graphite substrate support 3 and a sleeve The inner cover 4 on the outside of the substrate holder, the inclination angle α of the substrate holder 3 is 3°, the inclination angle β of the inner cover 4 is greater than the inclination angle of the substrate holder 3 by 3°, and the inclination angle is 6°, forming a reaction in which the upper area is smaller than the lower area The gas channel, the reaction gas is discharged from the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com