Sea floor corrosion-proof and silt-promoting system and its uses

An anti-erosion and seagrass technology, applied in marine engineering, pipeline laying and maintenance, water conservancy engineering and other directions, can solve the problems of increased construction difficulty due to self-weight, poor effect, slow subsidence, etc., to improve the bearing capacity of the seabed and improve the effect. , good effect of wave elimination and slow flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] The difference from Example 1 is:

[0047] Wherein the blade is made of polypropylene material with a specific gravity of 0.68g / cm 3 .

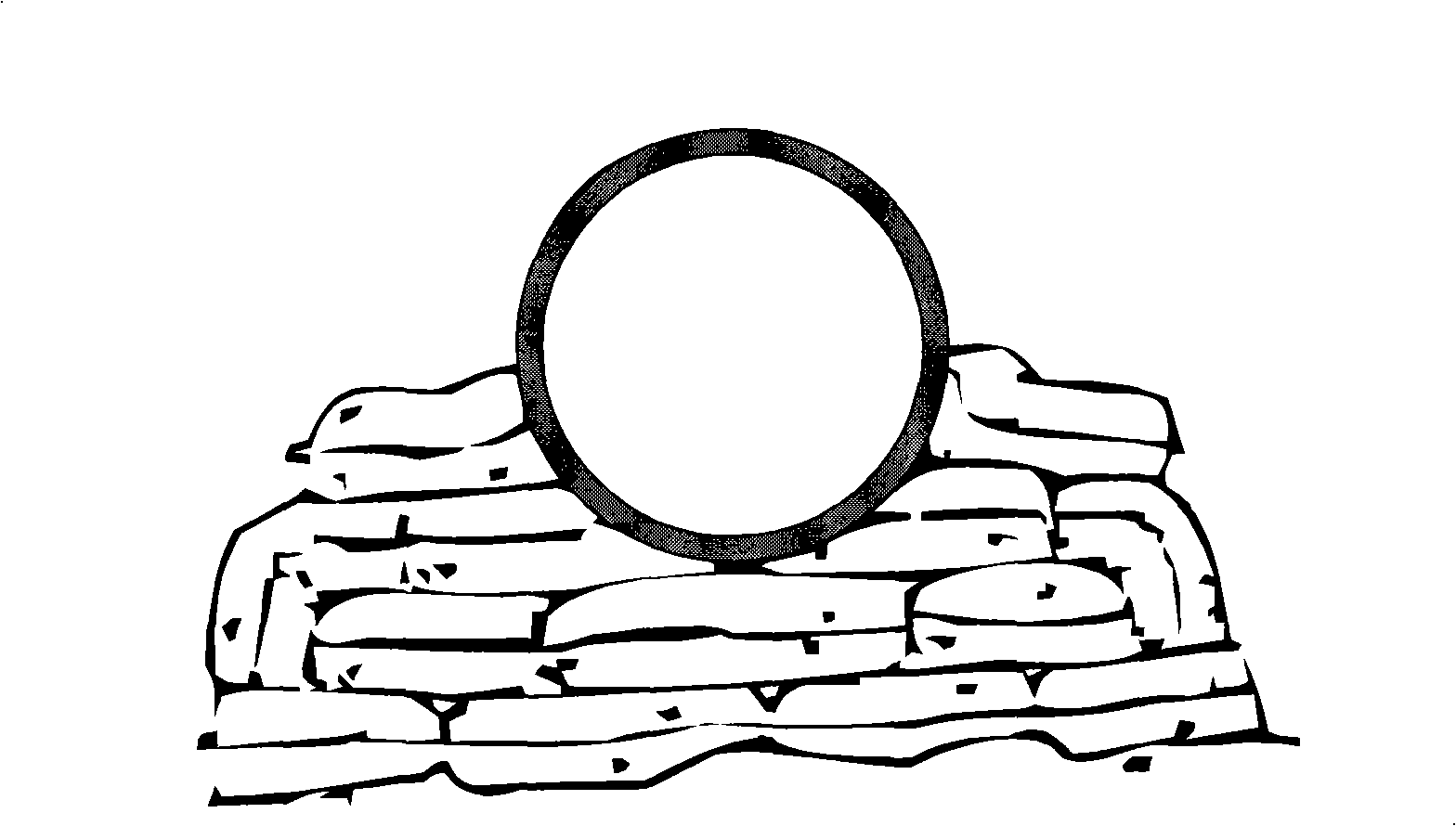

[0048] Submarine anti-erosion and silt-promoting system application: directly fix the artificial seagrass of the net-like flexible frame structure on the coastline where the seabed moves through the anchoring system (the seabed that needs to promote siltation or prevent erosion).

[0049] The present invention carries out the research result of artificial seaweed promoting sedimentation experiment. The results showed that the greater and denser the seagrass laying, the greater the reduction in flow velocity near the seafloor surface. Figure 9 Shown is the comparison of seafloor velocity when the beach without seagrass and the beach with seagrass experience the same tidal process, and the measurement results show that the beach velocity with the seagrass of the present invention is obviously smaller than the beach velocity without th...

Embodiment 3

[0051] The difference from Example 1 is:

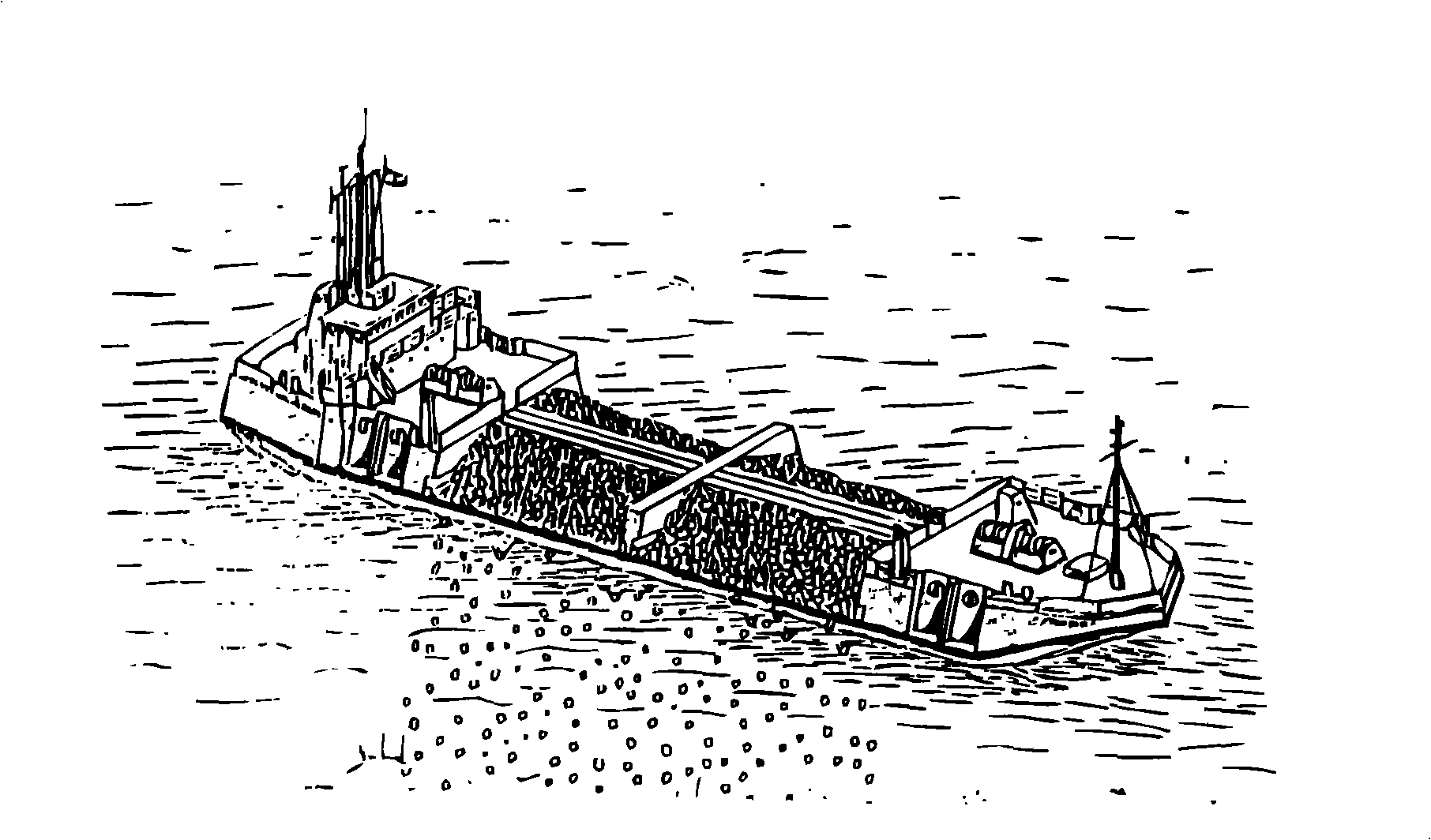

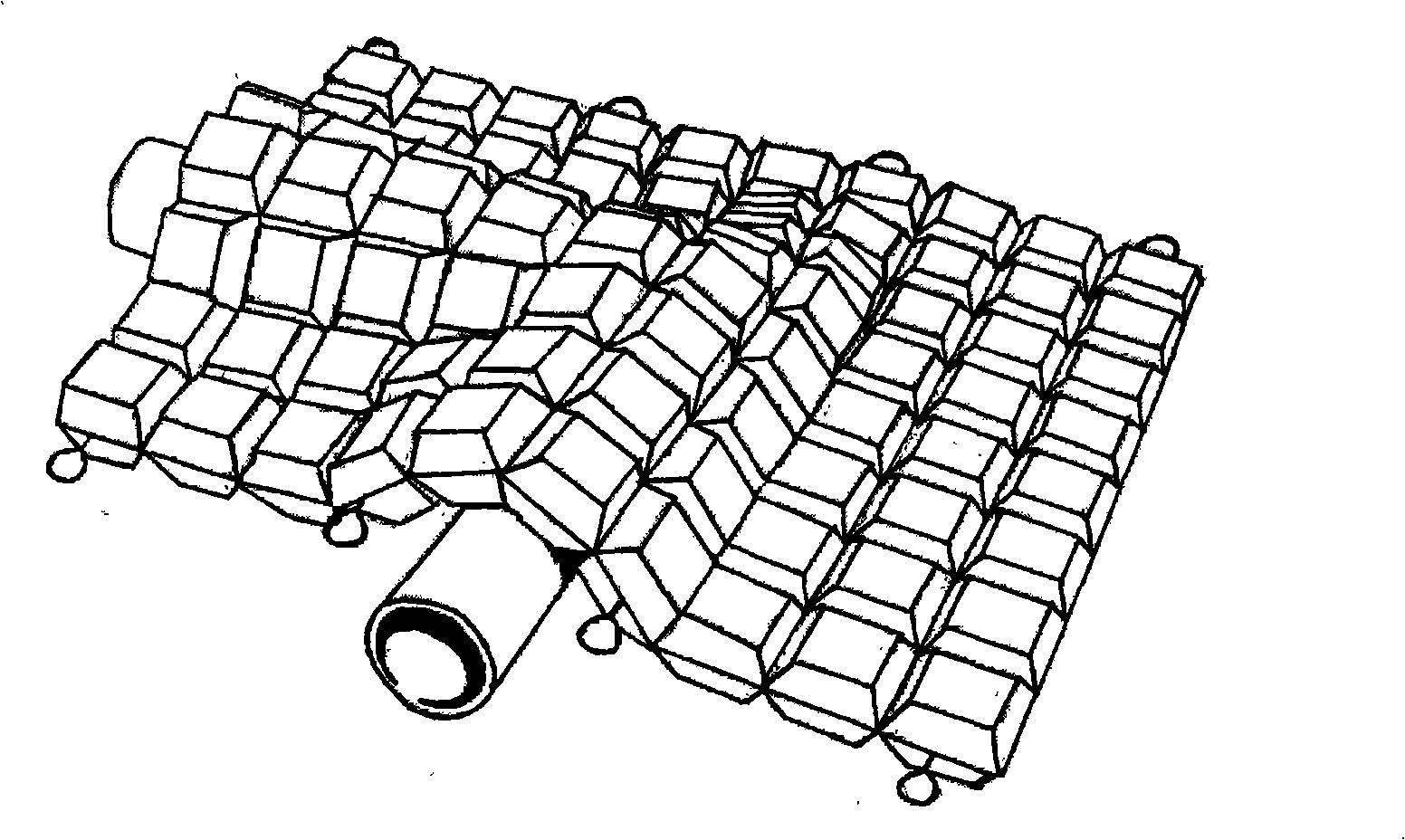

[0052] Wherein the specific gravity of the blade material is 0.4g / cm 3 . Subsea anti-erosion and sedimentation promotion systems are applied on the upper surface of pipelines laid on the seabed (see Figure 7-2 , wherein: the pipeline represented by the black long frame is covered by the artificial seaweed of the net-like flexible frame structure, 8 pieces of artificial seagrass of the net-like flexible frame structure in this embodiment are connected together and laid above the pipeline, and the position of each piece of anchoring system is laid see Figure 7-3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com